Do you know the large machine that creates things called an injection molding machine? It's quite fascinating! Now imagine that on an order of magnitude larger scale- one with a potential to produce parts as large as 4000 tons-and whose requirements specify precision levels in submicrons. Imagine how f***ing heavy that is!

This is what brings us to the subject of havoc, an indomitable force that lurks behind the intimidating visage of composite machinery which in this case happens to be a 400 Ton Injection Molding Machine, or rather confusion around it. This machine is in various factories around the world because it can churn out tons of product quickly. It works by melting the material directly into treating forms such as plastic, metal or rubber in a technique called injection molding.

The 4000 Ton Injection Molding Machine : Revolutionizing Processes And Productivity In The Manufacturing Industry Its remarkable resourcefulness saves energy and, by extension, cash. This leads to increased profitability and business growth as companies can expedite production while maintaining the highest quality. Certainly, it is one of those machines which has made manufacturing almost impossible without out in several sectors.

Utilized for mass production, the 4000 ton injection molding machine was a great solution to accommodate high demands and deliver orders quickly. Due to its many uses with a variety of mediums, it ranks as an extremely versatile ingredient in several industries. This machine is the essential part that businesses need in order to keep up with their production needs quickly and effectively.

4000 Ton Injection Molding MachineThe 4000 Ton injection molding machine stands out because of the impressive performances that make it unique when compared to other machinery. It is capable of producing items up to 4000 tons in weight, making it suitable for rendering large objects-such as car parts. Also, this machine plays a vital role in quality control by making the perfect shapes with precision and branded output; there was nothing to worry about it. We know that the 4000 ton injection molding machine is reshaping manufacturing with some really exciting attributes and its presence on-site.

To put it in simple words, a 4000 Ton Injection Molding Machine has become the backbone of mass production! Its effect on the industry is also observable, obviously increasing production procedures and helping resources with high demands become met quicker. This machine can work with a range of materials and ensures precision output each production cycle, it became the go-to tool for organisations all over the world. A 4000 ton injection molding machine is already at the forefront of disruptive technologies in manufacturing and will remain a key player for generations to come.

Pingcheng's 4000 ton injection molding machine and services are designed to helps customers meet their goals for business. We are focused on expanding and increasing the potential and lifespans of your productions. PingCheng is a dependable producers you are looking for. We are a suppliers that provides opportunities.

Our customer service focuses on your satisfactions. We have been offering an 4000 ton injection molding machine and developing a strong cooperation with industry well-known Japanese enterprises for over 20 years. Based on decades experience and comprehensions of this industry, Pingcheng is dedicated to offering our customers honest prices. We review the drawing using specialized software and provide most effective solutions at the most reasonable cost the moment we receives an inquiry for a quotes.

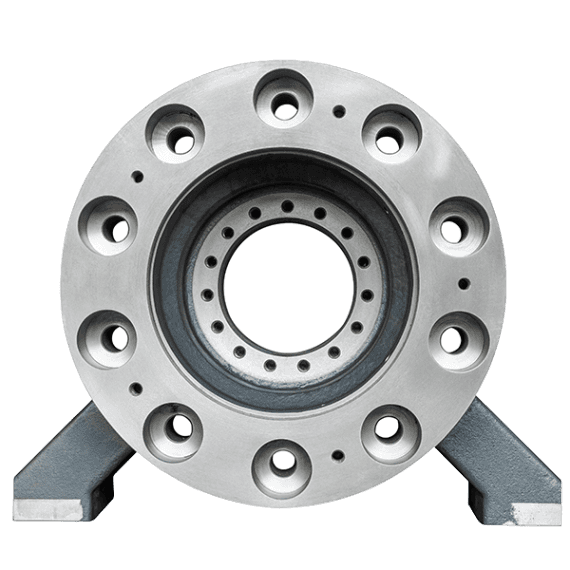

Pingcheng has at 4000 ton injection molding machine and 50 technical employees who have experiences. They are committed providing tops quality. Mitsutoyo's measuring instruments and CMM are calibrated regularly. The double-checking keeps quality reliable and accurate. Each keys part traceable and controlled during machining and assembly.

With decades of experience and comprehension of this industry, Pingcheng is dedicated to providing its customers with a fair price. Once we have received a the request for quote, we 4000 ton injection molding machine in our specialized software right away, and then provide the best solution for your cost.