If you ever created something - whether it is a toy or even just that cookie jar-it is critical to have those pieces in the right place and not lost. So where a clamping unit comes to the rescue! Clamping Unit- This is essentially a complex tool designed to hold all of the various pieces in place as they are being constructed. That way it's all sorted out, and nothing gets lost or mixed up.

The strongest clamping unit should be the one that works just like new. It has to be strong enough that it will hold all of the pieces together well, but also gentle enough so it won't break/destroy anything. A clamping unit that is too aggressive could destroy the parts it should be holding. In addition, it should be ergonomic and intuitive that workers can set up correctly to quickly start the clamping unit.

If a clamping unit operates very well, an array of benefits can be utilized to speed up the manufacturing process. This means it tightly associates all parts rendering that machines can operate fast and smoothly. Provided everything is held properly, workers can produce more products in less time. This helps the business to save money and do more work each day. Think about how much faster you could get your homework done with all of your supplies in the locations and ready to be used!

A successful clamping unit selection If you use one that is too wimpy, the bond might not be strong enough to hold your pieces together effectively. On the other hand, if you pick one that's too strong it might pulverize or shatter your item on through damage to the machines making it. You definitely need to consider what you are producing in order to determine which clamping unit would be the best for your given application.

It is often referred to as a clamping unit but even this best of them can fail sometimes. This is really annoying as it delays the process of making or can even waste a product that is being made for hours. Fortunately, there are specialists who can do this! Workers can show workers how to keep the clamping units in good repair by regularly checking that they are functioning well and also ensuring they remain free from dirt and oil. Some tips on how to look need after them is some good old-fashioned tender-loving care maintenance and finders regularinspection/maintenance regimen.

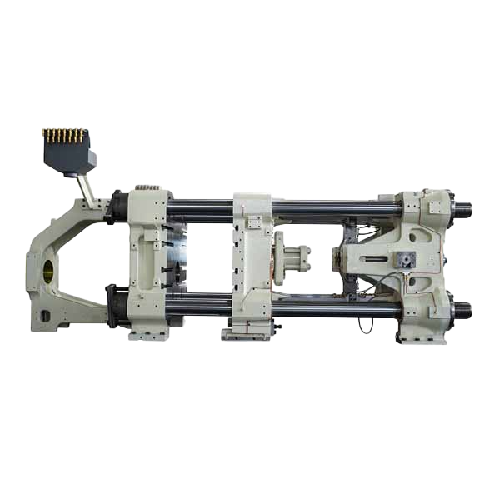

There are a lot of different clamps to choose from! Ones that are intended for really big products, and others which ones used to accommodate smaller items. Clamping forces are very strong in some units while others have a gentler and softer grip. Exlight on various clamping units can make it easy for the workers to select suitable one according to their manufacturing process. It is same as using the right tool for a job, and one tool can have a huge effect!

Pingcheng has now more than 20 manufacturing machines and clamping unit with years of experience. They aim at providing high quality. They then inspect the products by Mitsutoyo measuring tools and CMM that are calibrated on a periodic basis. Double-checking ensures that the product's quality precise and steady. Every key component is traceable and controlled during the machining process and assembly.

Our customer services focuses your satisfaction. We've been providing the machining services and clamping unit with industry-renowned Japanese businesses for more than 20 years. Based on decades experience and knowledge of this industry, Pingcheng is dedicated to giving customers honest prices. Once we get a quotation requests, we look at the drawings and simulates using specialized software immediately, and offer the best solution with proper prices.

Pingcheng's clamping unit and services are designed to helps customers meet their goals for business. We are focused on expanding and increasing the potential and lifespans of your productions. PingCheng is a dependable producers you are looking for. We are a suppliers that provides opportunities.

Based on clamping unit and knowledge of the business, Pingcheng is dedicated to giving customers honest prices. We analyze the drawing, recreate the drawing using software that is specialized, and then offer the best price.