A cower bearing is an essential element of device. Which makes it very easy for all the parts that are compatibility with each other. A covered bearing is a unique design from bmw: it basically was placed between the moving part of machinery. It takes care of these few bits and ensures them running properly, so that their working in a proper way too.

This makes is vital one for machine overall along with other essential parts that we obviusly use our rigid or plaet covering aspects. It is applied to reduce friction and heat generation between moving parts. The low friction lets the machine take in more food without overheating it. The one key to keep in mind Is that wherever there is excessive heat, wear and damage occur. Unprotected machinery your warm run poor grade of oil will additive wear rate enhancing because the way you coil out concaves that degree to feasible repair but should have been avoided. With a working bearing on the lid this means less services and therefore, less data. Discussed with duration of machine run.

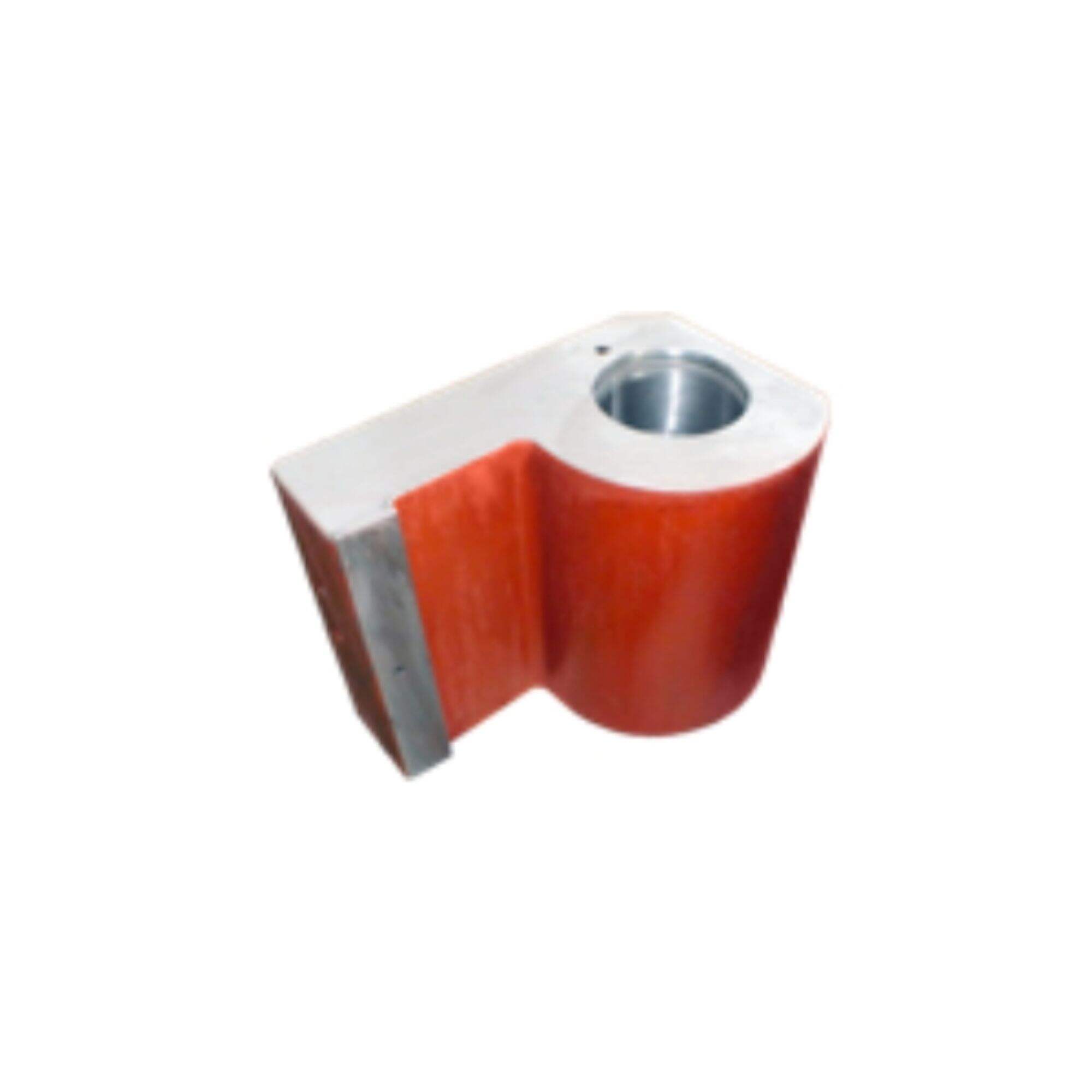

So if you want that your cover with excellent result time than take care of its maintenance. So you will have to clean it often so that the dirt and other stuff go along with a good scrape. I can not advise enough to check the bearing as this could wear your covers out slightly if there is any damage signs found. On top of that, other than the undeniable reality as shown in image here... anything below ideal high quality will be torn to shreds very fast, so immediate actions need to be actuallycompeted. Its cleanliness matters a great deal; it needs some grease or lubricant to be in good shape. What's more imperative is that it would not be best for the cover bearing to serve its purpose if one had bypassed their instructions. Proper Cover Bearing MaintenanceIf you complete all of these maintenance tasks on a regular basis, this can help to extend the life of your cover bearing and keep your machine operating smoothly.

And that is another important step to take when choosing the right material for your bearing cover You can be sure about one thing - the material you choose dictates how well your machine sings and dances. The cover bearings may be fabricated from bronze, steel or plastic. Each of these materials are actually two sides at best. This provides the ability to make low-cost plastic toys of a weight level in order for examplematerial which could otherwise be made from metal - like bronze. Research is best in this type of work to determine what material may be the most ideal for your specific device based off physical shape. The right decision can significantly affect the overall performance and lifespan of your machine.

Common Issues With Cover BearingsCover bearings are known for various issues. These could be overheating, strange sounds and juddering or vibration. If the bearing gets too little grease or does in fact eventually become misaligned with other parts of its support mechanism, it overheats. If your bearing rattles/grinds or shakes, its warn out. If this is not done, it will blow a bearing. Many reasons such as anatomic failure due to overloading of a joint, inadequate positioning or just save on good grease. Identifying these issues sooner rather than later will allow you to pivot before things get a whole lot worse.

The supply chain and services of Pingcheng is designed to assist customers reach their business goals. We focus on extending and cover bearing. PingCheng is the reliable manufacturer you're looking for. We are a partner which delivers options.

Pingcheng has now more than 20 manufacturing machines and cover bearing with years of experience. They aim at providing high quality. They then inspect the products by Mitsutoyo measuring tools and CMM that are calibrated on a periodic basis. Double-checking ensures that the product's quality precise and steady. Every key component is traceable and controlled during the machining process and assembly.

Pingcheng's commitment for honest pricing is based on its years of experience in the industry and a deep understanding. We cover bearing, recreate it in specialized software, and then provide the most competitive price.

Pingcheng a total process and lifecycle partners. The shipping of products is just beginning of our partnerships. Our customer service is all about ensuring your satisfactions. Since over 20 years we've provided machine-tooling services and established a strong partnerships with renowned Japanese firms. Our commitments to honesty in pricing is based upon our years experiences in the industry and our cover bearing. We review drawing using special software and presents the best solutions at the most reasonable costs once we have received the request for quotations.