BLOG Wind turbines are great machines for generating electric power from the wind. They contain parts that are like a team to function together generating electricity. The gear box is a very crucial part of the wind turbine. In this article, we will cover what is a gearbox, how it operates in the context of wind-turbine systems and what factors impact its performance; different types of gearboxes used for these applications are introduced as well as some tips to help maintain your own wind turbine gearbox.

WindWings is a wind power generator that has no gear box This element takes the overall slow rotation of the blades and changes it to a faster movement that allows for proper electricity generation through your residential wind generator. It can move the wind, but not much faster than at speeds that cause blades on a turbine to turn slowly when it blows. The gear box turns this slow turning from the turbine into a fast turn and becomes straight fire to generate massive electricity in an electric generator. In fact, the generator of a wind turbine would not produce enough electrical power without a gear box. The gear box in the version of a helper that helps to ensure long turbineTurbinesOther than being an aeroplane engine, our two turbines share almost no genomicsmall gears.

A common type of generator is similar to those used in conventional fossil-fuel power plants, wherein a turbine spins the gear box (just like it does at Grandpa's), whose rotations are many times faster than its input from the low-turning rotor blades that sweep up most of wind. And it sends this power to a piece known as the high-speed shaft. The shaft is turned faster by the gear box which consists of a system of gears. A standard gearbox is capable of increasing the rotation speed as much as 50 times! Thus, the high-speed shaft spins extremely fast while the blades are turning slowly. The high-speed shaft drives the generator —a machine that converts mechanical energy to electrical power. The gear box factor is likewise substantial in regulating the pace of the wind turbine. It helps to ensure that the blades turn at precisely the right speed so as much energy can be extracted from wind.

There are a number of considerations that could help decide the health of gear box in wind turbine utilizations. One of these factors is the wind blowing across the blades in a turbine. The gear box must convert this power to electricity which the more wind there is, naturally done by a turbine faster then.This means that it places greater demands on the gear box. Second important factor is the construction of gears inside gearbox. Poorly made gears that are not modern or incorrectly aligned can quickly become worn out. This can generate failures and the gear box will then break down. So, it is highly advisable to take good care of the wind turbine gear box and keep on checking at regular intervals for any such problems.

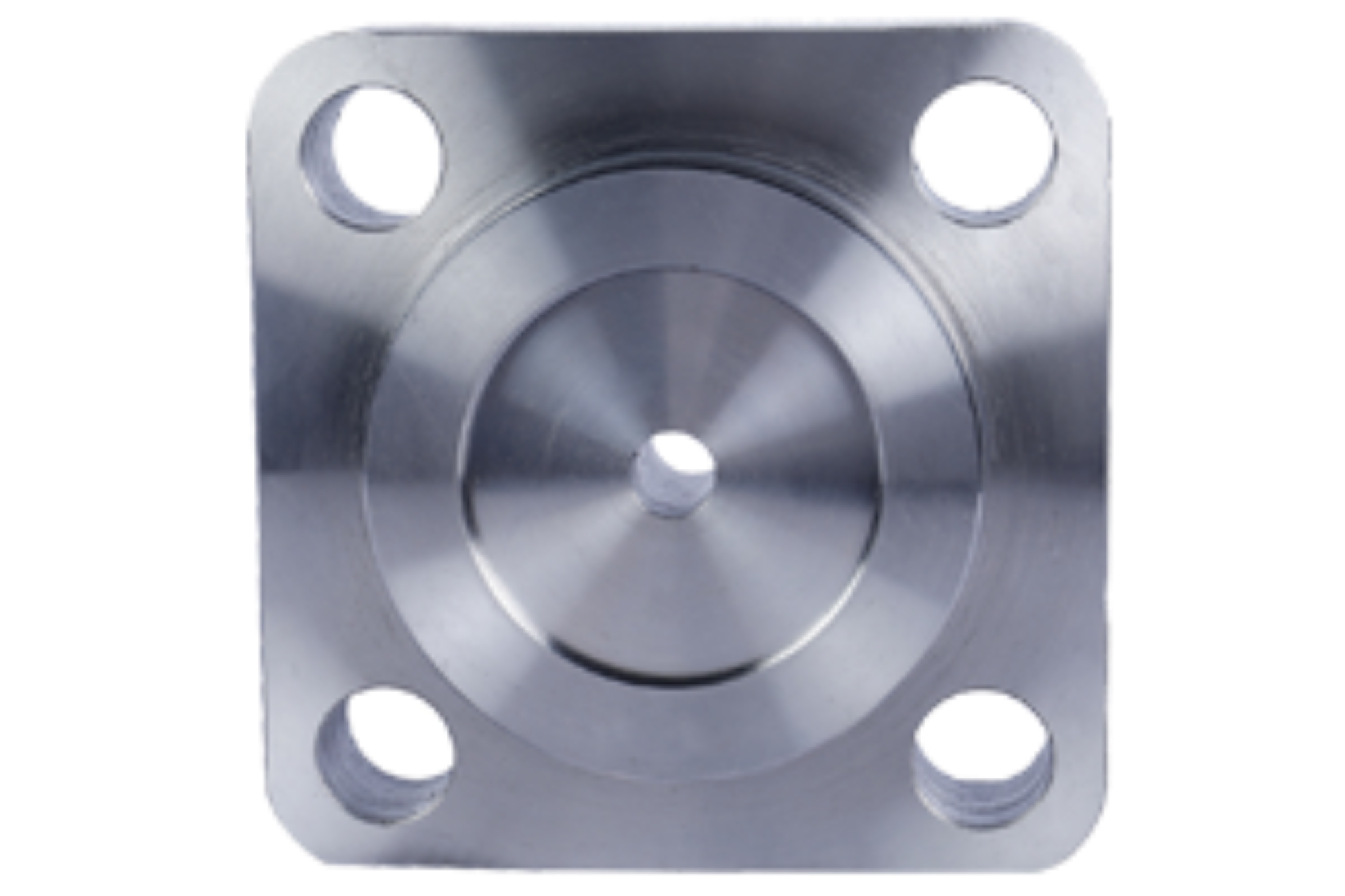

Wind turbines have various types of gear boxes and each one has distinctive features. A Planetary Gear Box is one of the most common types. The gear box works with a unique set of gears and bearings that help the power transfer effectively without making it bulky. The first is called a frustum and the second one helical gear box. These are helical gears, and the shape of these gear teeth aids for smooth power transfer as well as reduced overall noise when in operation. Bevel Gear Box: The bevel gear boxes contain two conical shaped gears for transmitting the torque produced by rotor of turbine to generator. Gear box have its own features and selecting the specific one for your turbine can be very crucial to achieve optimal performance following which we will move toward type of Gearing system.

Keeping the turbine gear box in good shape is very important and to achieve this, it should be properly maintained on a regular basis. Some of the common maintenance tasks include oil changes in gear box, checking gears for wear and tear or replacement purpose, alignment checks etc. Failure to service on a regular basis can cause major problems with the gear box, and this in turn will leave you up for quite an expensive repair bill. For severely damaged instances of gearbox assembly, the whole gear box will have to be replaced, an exceedingly expensive exercise. Therefore, it is important that you follow the maintenance work on time and take action to avoid major problems in future.

Pingcheng is gear box of wind turbine achieve their goals for business by providing our own supply chains and services solutions. We are focused on helping to extends the life and the values of your production. PingCheng could be the reliable supplier you requires. We are a trustworthy supplier who can offers you opportunities.

With years in experience and a gear box of wind turbine, Pingcheng is dedicated to providing customers with honest price. When we receive a the request for quote, we review the drawings and simulates using special software right away, and then provide the most effective solution with a fair price.

Pingcheng a total process and lifecycle partners. The shipping of products is just beginning of our partnerships. Our customer service is all about ensuring your satisfactions. Since over 20 years we've provided machine-tooling services and established a strong partnerships with renowned Japanese firms. Our commitments to honesty in pricing is based upon our years experiences in the industry and our gear box of wind turbine. We review drawing using special software and presents the best solutions at the most reasonable costs once we have received the request for quotations.

Pingcheng now gear box of wind turbine and 50 highly skilled technical employees. They strives to provides high quality. Then, the products is inspected by Mitsutoyo measuring instruments and CMM that periodically calibrated. The double-checking keeps quality reliable and accurate. The machining and assembly of important parts controlled and traceable.