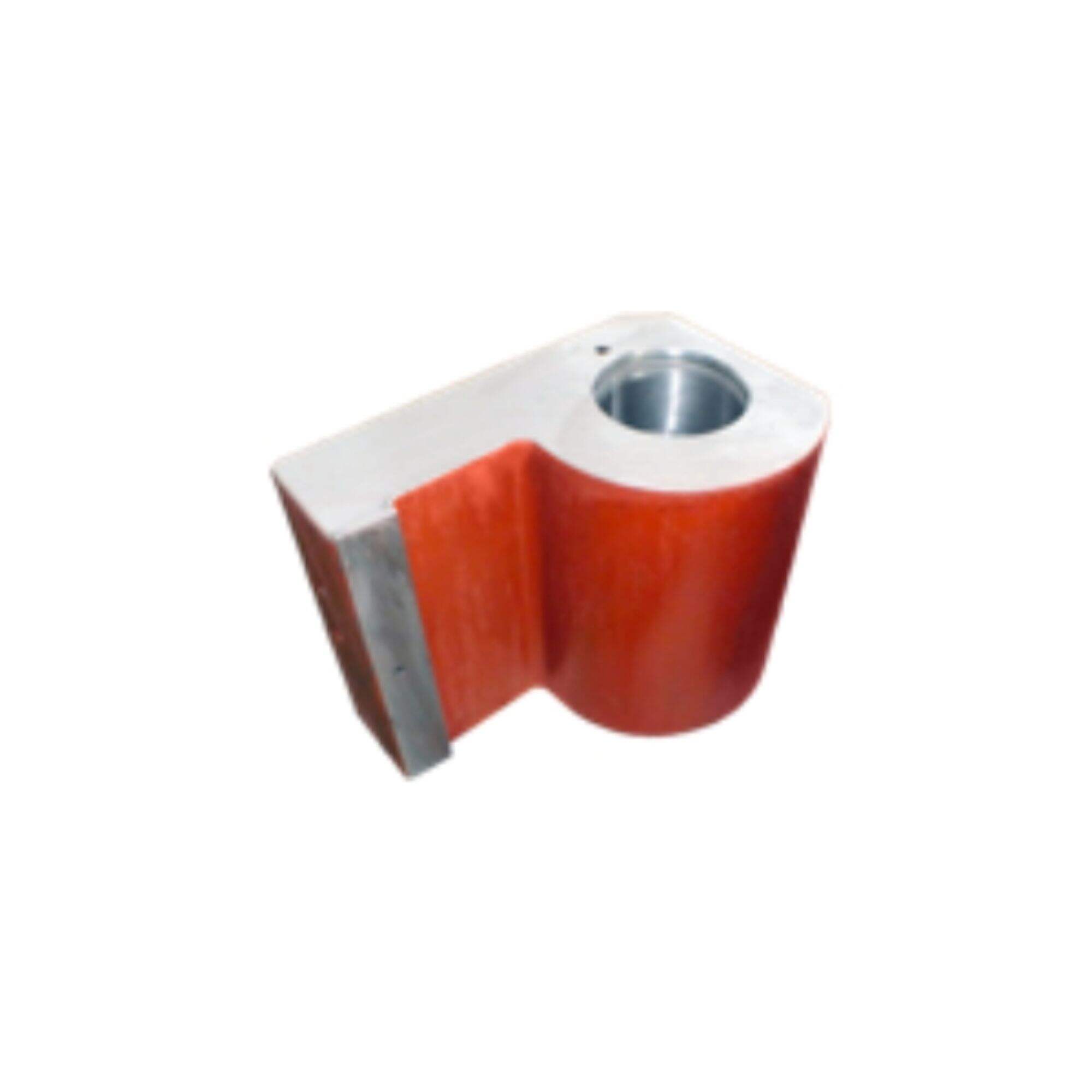

Hey kids! Interested in the heat platen hydraulic press, a dynamite machine? The Rachel Wolf used here was remarkable in that it accommodated a variety of materials (rubber, plastic and metal ores) for forming. They clamp these substances in the right shape utilizing an element know as pressure force, similar to how you can squash play dough out and make it look like a star or car!

We put it to work for countless tasks across different industries and this is still by far one of the best purchases we have ever made. Molding, laminating and bonding among others Actually Molding is to form materials, in lamniating both stuff get joined and bonding means meshing the things. On the day to day, this is a device car makers use when manufacturing cars, aerospace companies that are behind aircraft and even in any everyday production factory.

Heating is critical, for it quickens everything. Heating of compound are with less coolings after forming. This means that the machine can produce more products in less time. Therefore instead of having to wait long term for things cool down and require more time (which would be less productive)... this way whenever needs processing through just heat oil back up really quick than the stuff in there also becomes same tempate as well therefore making alot mroe widgets at one go then when parts have cooled off are moved out< shipped those all ready.

The truly remarkable thing about this machine, however, is that it can be amazingly precise. The ability to be accurate and precise is called Precision. The heated platen hydraulic press, on the other hand only maintains consistent pressure and heat levels per work cycle. This will be a way in determining that all the products produced are of the same sizes and shapes, which is greatly important when you consider what most businesses want to come out.

For example, airplane or medical instrument manufacturers are not allowed to produce anything less than perfection. You have to learn every little aspect of it, if one tiny thing goes wrong, then you can kiss everything goodbye! Hence an accurate device is required for the companies to produce such safe and well-treated products.

The heated platen hydraulic press is very easy to handle and maintain. For this reason, workers can be rapidly trained to learn how such a robotic system works and the best methods for its maintenance. It is a good tool to use if your business needs something heavy-dury that will get the job doney for years t same time there are some bugs part of objectegrate cage)

Now, how can heated platen hydraulic press help your production line? Utility - As we have already discussed, it is going to help you in more faster functioning which saves your time and money. But it also implies that those products are of quality, meaning they were built well than typical and will remain usable for long. Moreover, while the latter substitutes available on the market is there it will make these equipment capable of making products in different shapes as well as dimensions and departure this stuff significantly behind.

Pingcheng is total process and lifecycle partner. The supply of the products is just the start of our partnership. Our customer service about ensuring your satisfaction. We've been providing machining services and building close partnerships with heated platen hydraulic press for over 20 years. Based on decades of expertise and understanding of this industry, Pingcheng is dedicated to offering our customers honest prices. We examine the drawing with special software and presents the best solution the most reasonable costs when we receive offers.

Pingcheng currently has more than 20 manufacturing facilities and 50 highly skilled technical employees. They heated platen hydraulic press. Mitsutoyo's measuring instruments and CMM are periodically calibrated. The double-checking keeps our quality steady and accurate. The machining and assembly of all key parts are tracked and controlled.

With years in experience and a heated platen hydraulic press, Pingcheng is dedicated to providing customers with honest price. When we receive a the request for quote, we review the drawings and simulates using special software right away, and then provide the most effective solution with a fair price.

The supply chain and services of Pingcheng are designed to help clients achieve their goals in business. We concentrate on extending and increasing the potential and lifespan of your manufacturing. PingCheng is a heated platen hydraulic press you've been searching for. We are a partner which delivers opportunities.