Definition: Hydraulic press platen is a component of (hydraulic) machine namely as hydraulic press. It is nocest of machine one, where two material are pressed heavily together.) The plate which stores the materials to be printed securely on a flat surfce. A force is produced between this platen and the mold as machine presses in. The materials change shapes that are new or stronger when a significant pressure develops due to it) This process is especially beneficial for countless other industries as well.

In fact, this is quite useful: the hydraulic press pantheons. They do this by allowing workers to apply large amounts of force with little effort. This is useful very much for most of the projects that need to put a lot pressure and over big surface area such an example would be making metal parts, shaping materials. This one characteristic of the hydraulic press platens make them useful as workers are able tor work quickly, removing sludge easily and in large amounts.

Clean Healthcare Ranges Platens habitually to cut out Hydraulics Trouble Make certain it is certainly modified correctly and you are applying the needed burden when utilizing them. By doing all the above operation properly, platen will obtain long lasting as well it provides better performance. This means it is slowed down wear and tear, ie with proper maintenance we will not consume so much of them that do not care about anything or at least less than without any breaks.

New technologies also can improve the treatment of hydraulic press platens, and learn how to treat them even better through cutting-edge technology. It allows workers to control pressure on different areas of the platen. This enables workers to exert the right amounts of pressure necessary for particular tasks. This can help to avoid mistakes and waste, leading to increased efficiency in the process.

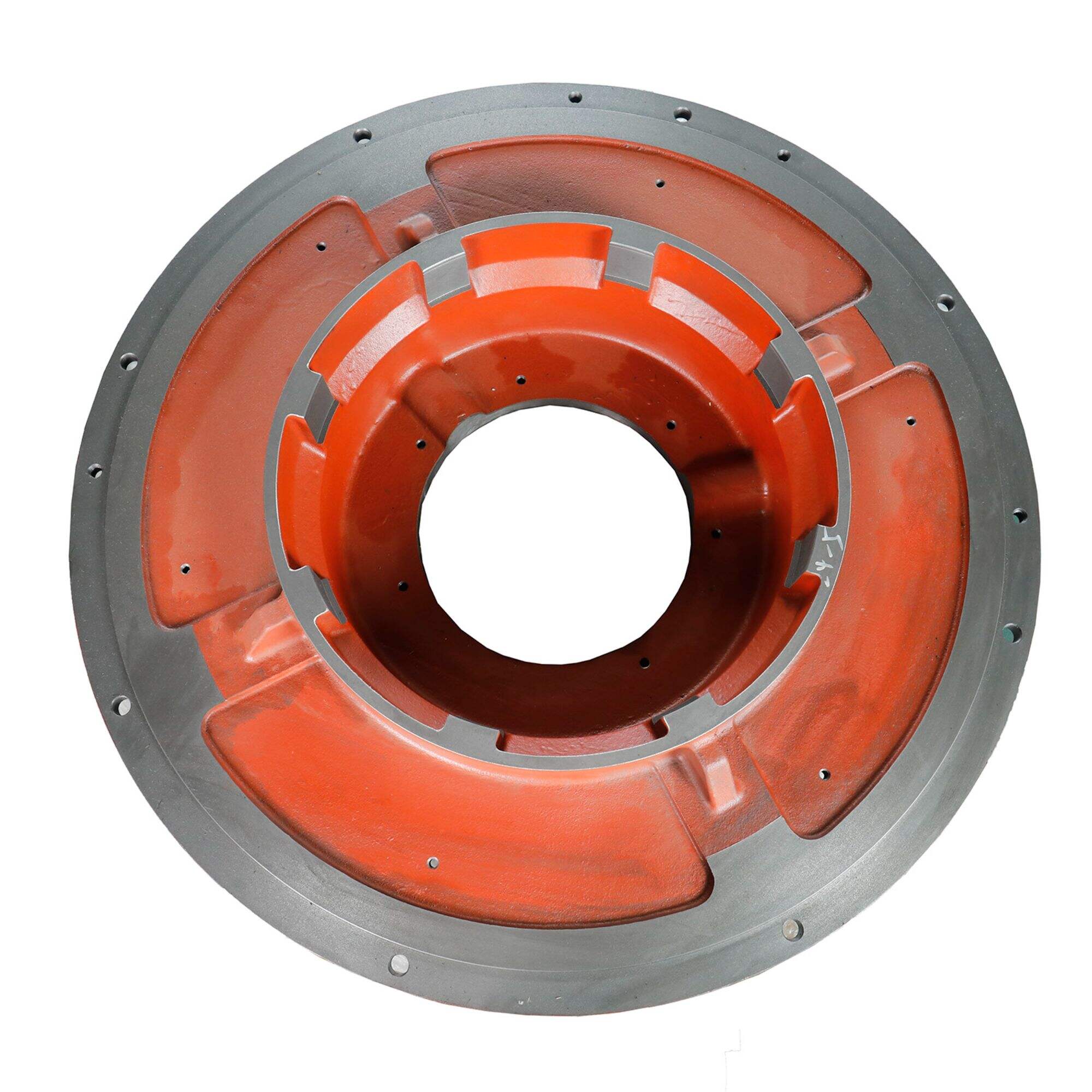

Hydraulic press platens that are designed for these types of jobs can come in many different size and shape variations. This can also vary depending on what they are made from, and as such the process will sometimes be different. For example, some platens are made of hard metal; others are built from soft rubber. And What the Platen Materials Are- This too can dictate how well a platen performs and its purpose. They can help to determine which platen may work best for your project if a machine is needed.

Regular cleaning and inspection of hydraulic press platens is necessary. Workers should also be on the lookout for these issues, as some of the same things that led to one may lead to problems if not addressed and fill in again any small dings or holes while raising sawdust. They need to be maintained in the best condition possible so they can run properly and you should do this through regular maintenance. Workers are also required to keep the platen with regular lubrication, this ensures that all parts moving together in tandem are able to do siz within their normal limits and reduces forming rust or other issues.

Our customers service focuses your satisfaction. We've been providing machining services and hydraulic press platen with industry-renowned Japanese companies for more 20 years. Based on years of experiences and knowledge of the industry, Pingcheng is dedicated to offering our customers an honest price. We evaluates the drawings using special software and present the best solutions at the most reasonable costs once we have received requests for quotations.

Pingcheng is now home to more than 20 manufacturing facilities and 50 experienced technical workers. They hydraulic press platen. Then, the product is inspected by Mitsutoyo measuring instruments and CMM that are periodically calibrated. Double-checking makes sure that the quality of our products precise and steady. The machining and assembly of all the key components are controlled and traceable.

With decades of experience and comprehension of this industry, Pingcheng is dedicated to providing its customers with a fair price. Once we have received a the request for quote, we hydraulic press platen in our specialized software right away, and then provide the best solution for your cost.

Pingcheng is dedicated to helping customers hydraulic press platen by providing our supply chains and services solutions. We strives to help you extends and maximize the life and worth of your products. PingCheng is the reliable manufacturers you're looking for. We are a company that delivers potential.