Those days, M/c was very much simple because it use to do only basic operations and hardly had some complex parts. Yet with an evolution in technology, machines too have refined. The linear slide rail guide is one important ingredient that has seen such subsequent development over time.

Linear slide rail guides were born in the 1930s with the first linear guide. Originally metal, this was to guide a drill press. In the following years, they made other packaging guides from new materials like plastic and so forth. Now, several types of linear slide rail guides are available which can be used for different machines and will demonstrate the evolution and multitude-readable this vital addition.

The basic info of the linear slide rail guide is that it helps a machine to move in one straight direction. This part allows a machine to move smoothly and accurately while working, helping make the machinery work faster with greater accuracy. All these, overall lead to a more accurate input and thus faster production with better quality of the output.

For example, when components in the creation of auto car parts are prime focus this ensures each part can be perfectly fitted together. If your DY parts are not accurate, they will not line up properly and this can cause the vehicle function improperly. A linear slide rail guide provides the accuracy ensuring that only high-quality parts are made over and over again

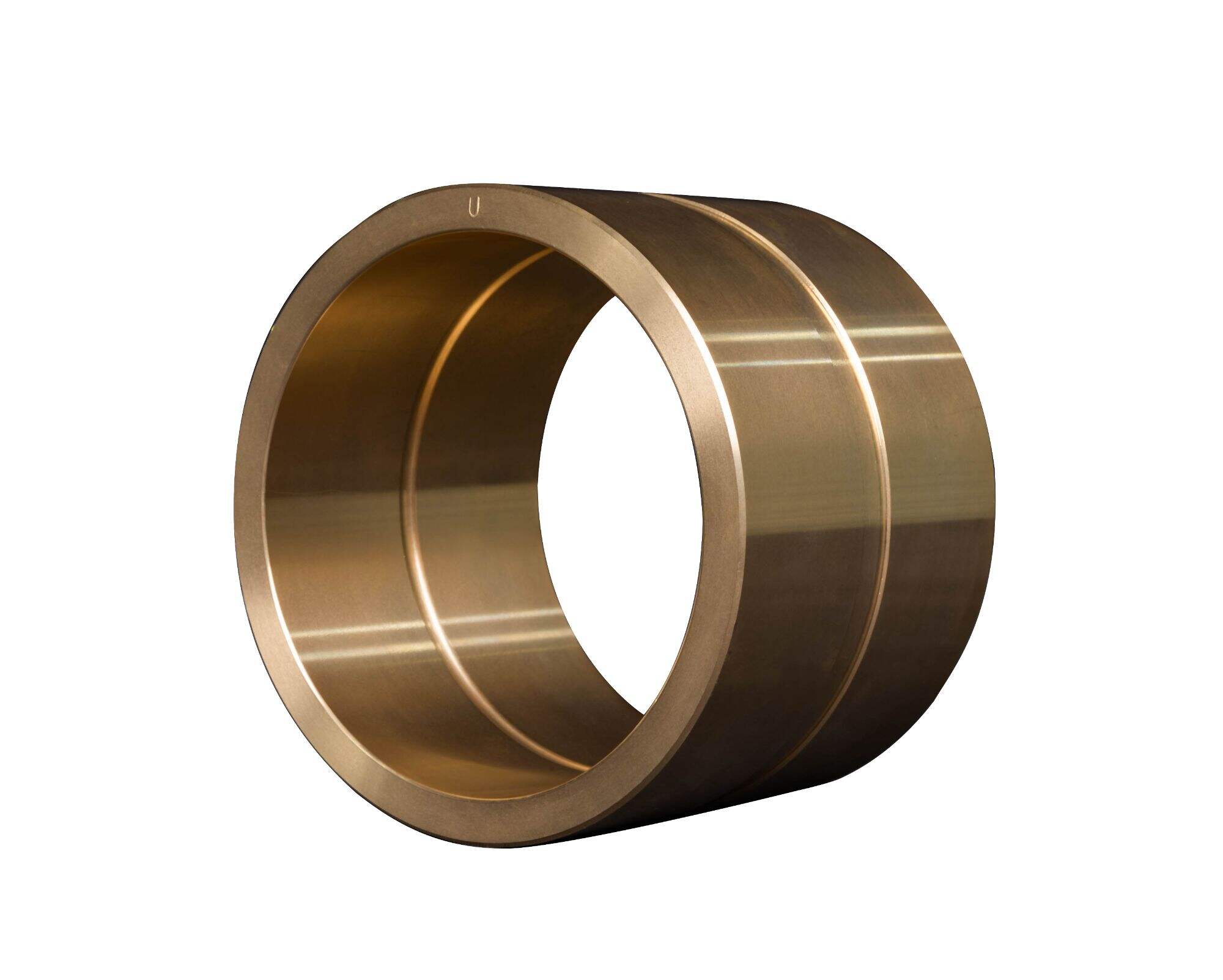

Linear slide rail guide is composed of two main components: the first one which iessentialy a lineare and could be seen anywhere, then there isthe block. The rail is something that the machine builds (usually out of metal or plastic) and the block represents a smaller part moving around on this constructed set.

The block, with the bearings in place travels along smoothly on the rail allowing for precise and smooth motion by our machine. Linear slide rail guides can be used in a wide variety of applications and machines such as lathes, mills, printers etcetera which states the importance it holds in different industries.

Industrial automation is the process followed where machines have taken over human labour in different tasks. This concept, of course drives us to automated machines which run on a single re-usable software - linear slide rail guides Industrial automation: In nearly all areas of production, and especially those that make use of mechanical processes, there exists a wide range of technologies Automation which including - but not limited to - electrical motors; fluid power actuators, sensors and so forth could be installed at the plants studied.

Linear slide rail guides add to the accuracy and precision of machines resulting in error free functioning, which is very important for light industrial used settings. This trust is critical in industrial automation which can quickly translate errors into dollar amounts.

In a machine that requires linear motion, a complete Linear Slide Rail Guide System can improve its performance. This includes the rail, block and bearings, all of which will enable you to move along the rail very quickly.

Types of Linear Slide Rail Guide systemLinear slide guide rail systems are available in different types. These can be made from metal, plastic and even a combination of the two materials together. Choosing the right system requires looking at what each machine is needing as machines differ from one another and require different solutions to ensure they are functioning properly.

To sum up, one of the most indispensable part in many machines is undoubtedly linear slide rail guides that enable you to move straight back and forth accurately. Machine operators can make sure that they are able to efficiently and effectively perform tasks at increased rates with the use of a proper linear slide rail guide system integrated into their machines. Therefore, machines that need linear motion typically and generally benefit from a little addition of the dose of highly regarded as well as quality Linear slide rail guide system combinations.

Pingcheng is committed to helping customers realize their business goals through our supply chain and linear slide rail guide. We concentrate on helping you increase the lifespan and potential value of your products. PingCheng can be the reliable manufacturer that you need. We are a trustworthy partner that can provide opportunities.

Pingcheng a total process and lifecycle partners. The shipping of products is just beginning of our partnerships. Our customer service is all about ensuring your satisfactions. Since over 20 years we've provided machine-tooling services and established a strong partnerships with renowned Japanese firms. Our commitments to honesty in pricing is based upon our years experiences in the industry and our linear slide rail guide. We review drawing using special software and presents the best solutions at the most reasonable costs once we have received the request for quotations.

Based on linear slide rail guide and knowledge of the business, Pingcheng is dedicated to giving customers honest prices. We analyze the drawing, recreate the drawing using software that is specialized, and then offer the best price.

Pingcheng is now linear slide rail guide and 50 highly skilled technical employees. They committed to providing highest quality. Mitsutoyo's measuring instruments and CMM are calibrated regularly. The double-checking keeps quality reliable and accurate. The machining and assembling of all keys components are easily traceable and controlled.