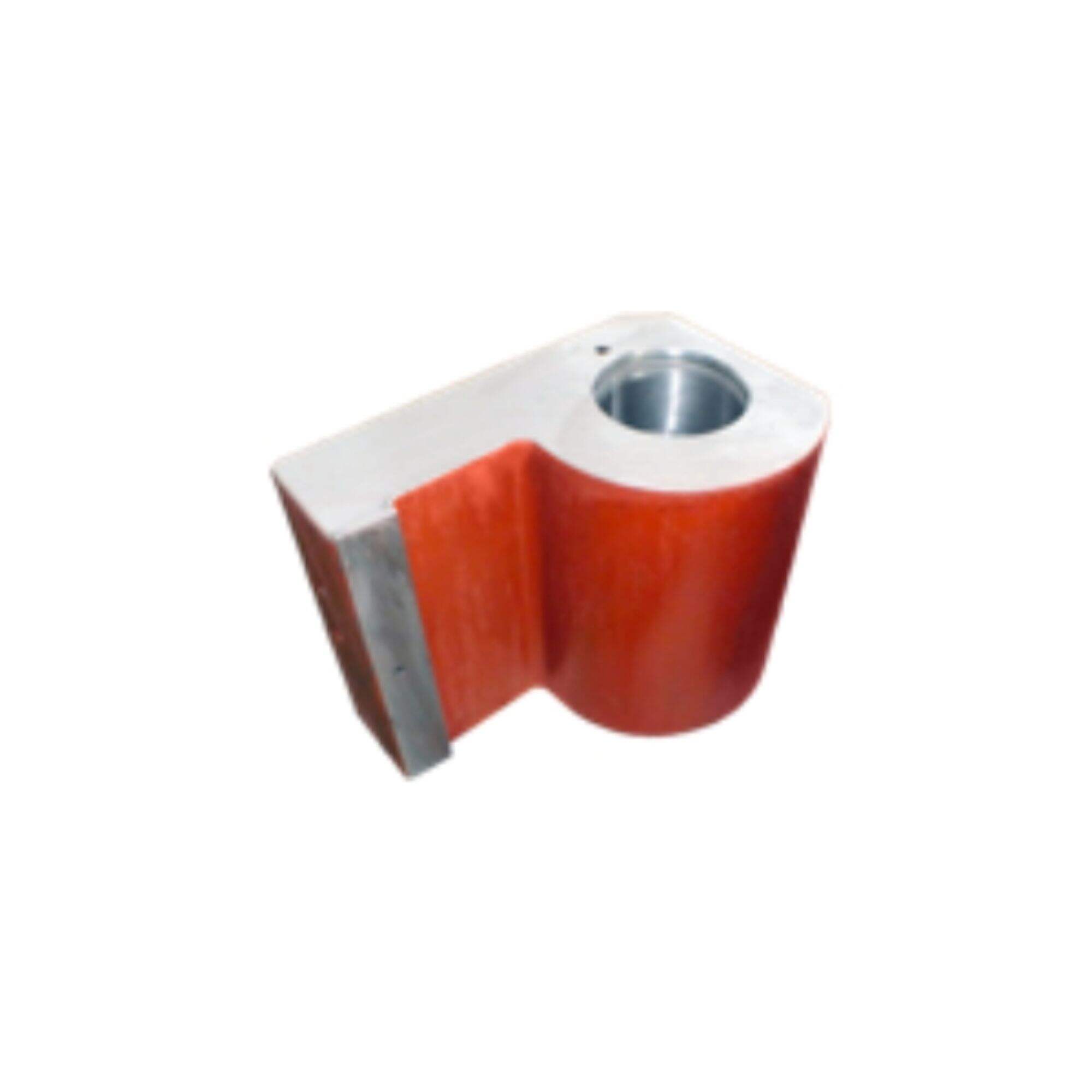

Manifold Block as a special part to make machines work better and in more effective way. It is actually constructed of robust steel and has many microscopic holes in it. These pores enable the liquids to flow through one location to another effortlessly without any choking or holdups. Here, we will look at the Manifold Block what it is and how does it work & why they are significant for machines across these diverse settings.

A typical application for using pressure to facilitate the transfer of a liquid (usually oil or water) from one part of a hydraulic system to another. These systems have many complex elements that must function together in unison to provide their intended use. Manifold Block Is a Key Component of this System The Manifold Block acts as if it were the brain of liquids, diverting them where you need to. Liquids may not get to where they should, or the liquid may flow poorly. That can cause dysfunction and limit the systems efficiency of carrying out its tasks.

A pneumatic system, by contrast uses air to power machines. These systems also demand that few components must be operating in symphony. The HIGHEST PIECE THAT IS USED IN THE PNEUMATIC SYSTEM WHICH WHAT WE GONNA TALK ABOUT IT Manifold Block. Think of the Manifold Block as a traffic light for air- it tells the air where to go and helps in guiding its movement through your system! That is critical as it demonstrates where the air should be sent and when so that there are no delays or disruptions.

It is also simple to connect the Manifold Block with other parts of a pneumatic system. These small and compact design reduced the space genome, as well employed in hydraulic system. You can simplify things even further by replacing the three-way valve with an additional Manifold Block. This simplification then allows the system to operate much more fluid and reduces the chances of issues or failures happening.

There are so many different pieces that need to fit together perfectly in the realm of industrial automation. There has to be some reliability and ease of maintenance in these parts. In this scenario, a Manifold Block is essential because it helps in directing the flow of liquids or gases to where they are supposed to be which ensures machines function as intended. It enables the smooth operation of various equipment in a factory or industrial setting.

Fresh installation of a Manifold block obviously saves your time and money for maintenance and replacement costs in case you encounter failures everyday during operation of the pneumatic unit. This purpose of the Manifold Block is so you can easily service and replace blocks, if one breaks you don't have to stop all your system. This way, your work may proceed with ease. A well functioning Manifold Block offers you peace of mind that your automation system will work productively and earn you profits in the long run.

A Manifold Block helps you facilitate better, more reliable flow for those liquids in your fluid power systems. This improved flow makes the machines durable in longer run and helps them execute their task more efficiently too. It also helps to minimise the costs of unscheduled maintenance. The Manifold Block is as simple to set up, keep and change that it actually ends up being a cost-effect system for your plant.

Pingcheng today has more than 20 manufacturing facilities and more than manifold block. They aim at providing high quality. Mitsutoyo's measuring devices and CMM are regularly calibrated. Double-checking helps keep the accuracy of our products and steady. Every single component can be traced and monitored during machining and assembly.

Based on manifold block and a deeps understanding of the business, Pingcheng dedicated to providing its customers with a fair prices. When we receives a an inquiry for quotes, we look at the drawings and simulates using special software immediately, and offer the most effective solutions with a fair costs.

Pingcheng is committed to helping our customers reach their goals in business through our own supply chain and services solutions. We are focused on helping to extend and manifold block of your products. PingCheng is a dependable manufacturer that you're searching for. We are a trustworthy supplier of opportunities.

Pingcheng is a manifold block and lifecycle partners. The shipping of our products is only the beginning of our partnerships. Our customer services is about ensuring your satisfaction. Since more than 20 years ago, we have offered manufacturing services and have built a closed collaboration with well-known Japanese firms. Pingcheng's dedications to fair pricing is based upon our years of experiences and understanding of this sector. We analyze the drawing in an advanced software program and then provides the most efficient solution at the most reasonable cost once we have received the requests for quotation.