With CNC milling machines, every type of shape and design can be used. They are widely used for many sectors, including manufacturing of aircraft, automobiles and electronic devices. A CNC mill is a piece of equipment that uses a computer to control parts that cut, shape, and drill materials. This allows the machine to perform extremely fine tasks. It removes material from a larger lump to yield a finished product often highly intricate. What Are The Essential Components Of A CNC Milling Machine?

CNC milling machine has one of the crucial components called spindle motor, also the Pingcheng's product such as gearbox for small wind turbine. It is used to rotate the tool that cuts or shapes the material. The computer that is controlling the spindle motor keeps it spinning at the correct speed, which is essential for clean and accurate cuts. If the spindle motor does not spin correctly, the tool may not function properly, causing the final product to be unsightly.

The tool holder is another component used to hold the cutting tool in position as the machine works, the same as linear slide guide rail developed by Pingcheng. The caliper has a wide base, which allows for stabilization while cutting. If the tool wobbles or shifts, that can cause issues in the finished shape. Tool holders can are available in few shapes and are manufactured from high-quality-holding metals, these type of tool holders are made from durable steel or carbide, which makes them have improved durability and prolonged performance.

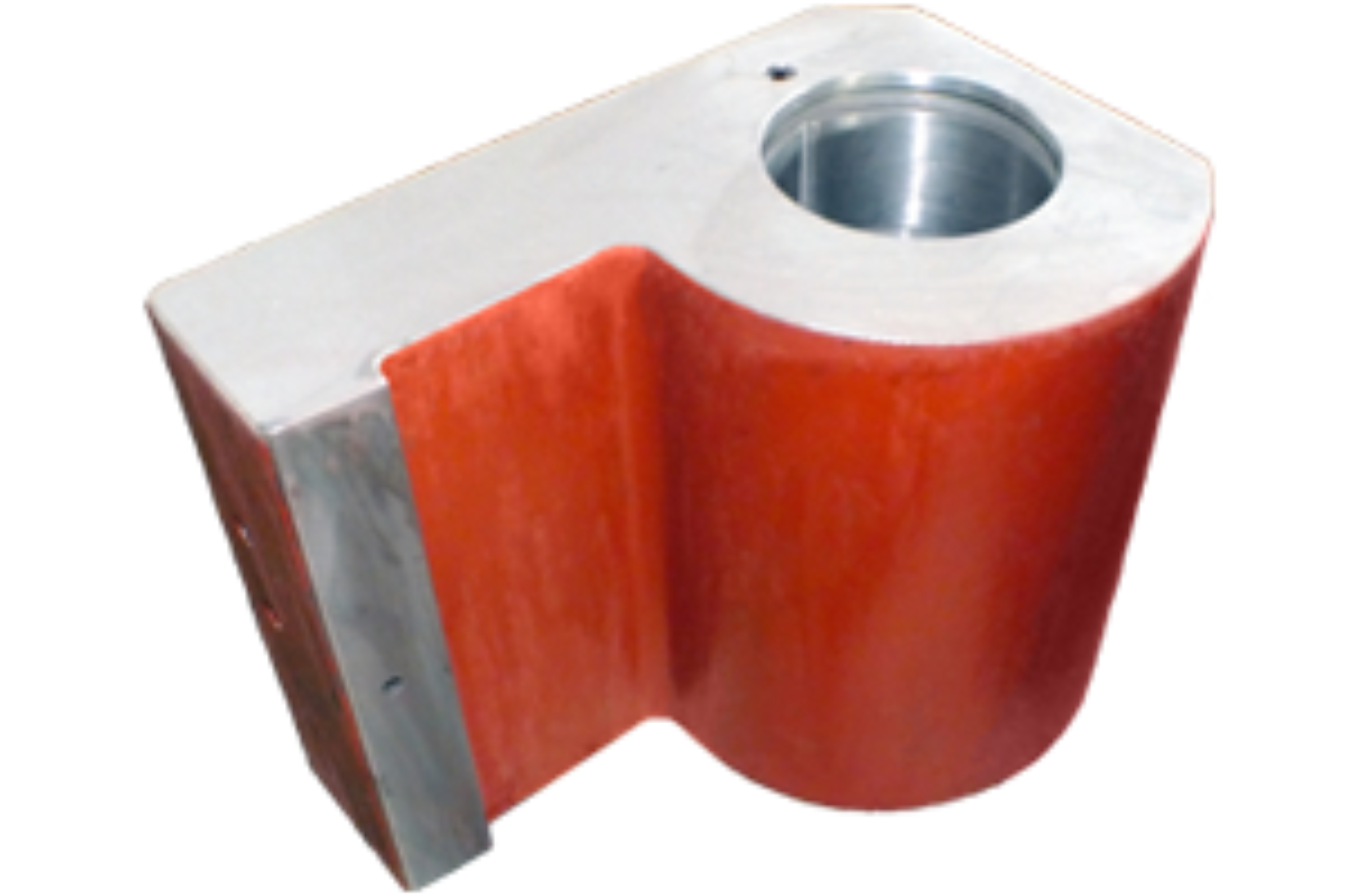

Another important part of a CNC milling machine is the ball screw, similar to the Pingcheng's product like heat press sleeve platen. They aid in converting rotational motion into linear movement. Meaning, they operate the spindle motor and cutting tool. They are manufactured for high precision and thus are used extensively in CNC milling machines. It is this accuracy which lets the machine produce extremely intricate designs and shapes.

A coolant system is an essential component for each CNC milling machine, along with the air manifold block built by Pingcheng. This helps maintain lower cutting tool and material temperatures during machine operation. Heat unpleasantment is when it gets so hot, it can urn into bad quality work. The coolant system helps to prevent the tool from getting too hot, which ensures that everything is working correctly and that the final product comes out in excellent condition.

The table is one of the significant components of CNC milling machine, similar to the Pingcheng's product like different types of flange. It is mounted on the bed and serves as the surface for the material to sit on as it is being cut. The top should also be flat and solid while supporting the weight of the workpiece. Issues with the Stability of the Table: If the table is unstable or not level, it can cause problems with the cutting process.

Based on Cnc milling machine components and knowledge of the business, Pingcheng is dedicated to giving customers honest prices. We analyze the drawing, recreate the drawing using software that is specialized, and then offer the best price.

Pingcheng is now Cnc milling machine components and 50 highly skilled technical employees. They committed to providing highest quality. Mitsutoyo's measuring instruments and CMM are calibrated regularly. The double-checking keeps quality reliable and accurate. The machining and assembling of all keys components are easily traceable and controlled.

Pingcheng is committed to helping customers achieves their business goals through our Cnc milling machine components and service solutions. We concentrates on helping you extend the life and values of your production. PingCheng is the dependable manufacturers you're looking for. We are a company that delivers options.

Pingcheng a total process and lifecycle partners. The shipping of products is just beginning of our partnerships. Our customer service is all about ensuring your satisfactions. Since over 20 years we've provided machine-tooling services and established a strong partnerships with renowned Japanese firms. Our commitments to honesty in pricing is based upon our years experiences in the industry and our Cnc milling machine components. We review drawing using special software and presents the best solutions at the most reasonable costs once we have received the request for quotations.