Why Hydraulic Accumulator Pressure is Important in Hydraulic Systems - An Overview

Within the hydraulic system world, an important element for boosting efficiency is presented by Pingcheng low pressure hydraulic accumulator because these parts are important to work as whole in the most optimum manner for hydraulic systems. A key consideration with hydraulic accumulators is how much pressure they can hold. This pressure is the force acting of fluid in an accumulator called as Hydraulic accumulator pressure.

With respect to performance, the key parameter in a hydraulic accumulator is pressure when used with other hydraulics. This pressure decides how large an accumulator is and, hence, its fluid holding ability. More nuanced for other hydraulic system parts, especially those requiring the correct pressure to operate properly. The hydraulic accumulator receives fluid, and stores its pressure then lets it out when the system needs some extra power. As such, the pressure level has a direct impact on how much energy in total can be held by the system.

Furthermore, it largely controls the performance of Pingcheng low pressure hydraulic accumulator in that they provide smooth functioning. Its function is to absorb pressure spikes and maintain system pressure under a low-pressure drop for some hydraulic pressures, it can change a lot (forcing both pumps and motors or actuators wear faster). However, an accumulator evens out system pressure changes when under a drop in pressure by decreasing pressure fluctuations and stress on other parts of the system.

Avoiding Subgrade Downtime with the right Pressurized Hydraulic Accumulator Pressure

Maintaining the pressure of hydraulic accumulators to appropriate levels is essential for reducing failures and other system problems before they occur. An excellent way of keeping up with pressure levels is by having the accumulator checked on a regular basis. Maintaining oil release; Monitoring the pressure level of other components and testing accumulator parts for signs of wear, leaks.

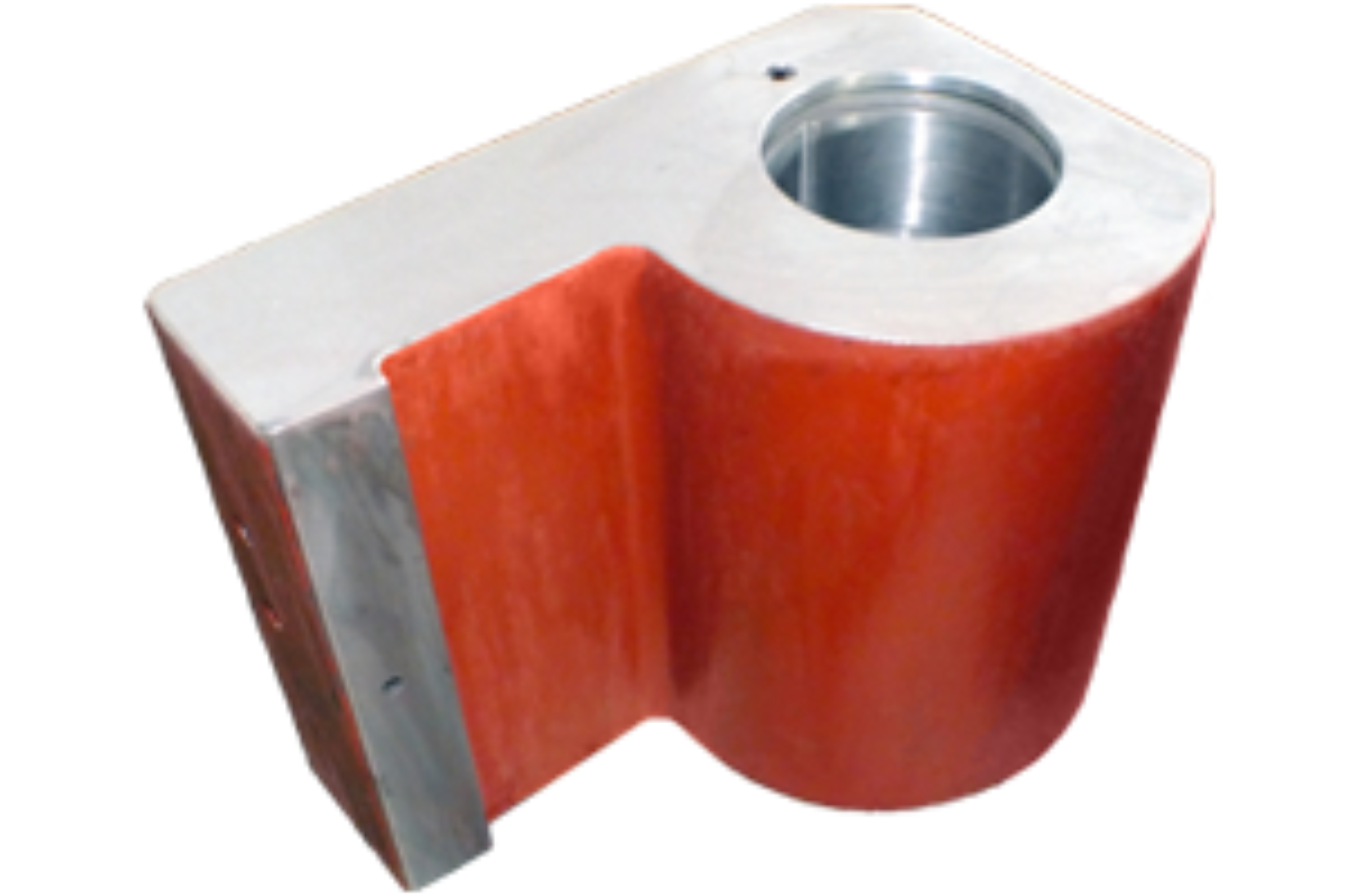

The cleanliness of the Pingcheng accumulator cylinder is another significant part to avoid dirt and debris from contaminating. Contamination can hasten seal degradation, which will cause the seals to leak pressure within the accumulator. Also, the hydraulic accumulator must be separated from their systems and act to remove all pressure before commencing any job.

Low hydraulic accumulator pressure can lead to decreased efficiency, extended downtime and premature failures within the hydraulic system. Deaths due to low pressure levels most commonly occur when the bladder or piston in the accumulator fails. When an accumulator fails, it will lower pressure levels and sound alarms of vibrations and the hydraulic system overheating.

In addition, not having the accurate Pingcheng accumulator cylinder pressure-maintained overloading on systems parts such as pumps, motors, valves and actuators. This strain speeds up system wear and tear, which can reduce performance. In more extreme events, such as when hydraulic accumulator pressure is low enough that a pressure drop within the system occurs it may generate failures or damage to sensitive components.

· Maintain peak hydraulic system performance by following these recommendations and best practices.

· Frequently check the hydraulic accumulator and system components for signs of maintenance needs.

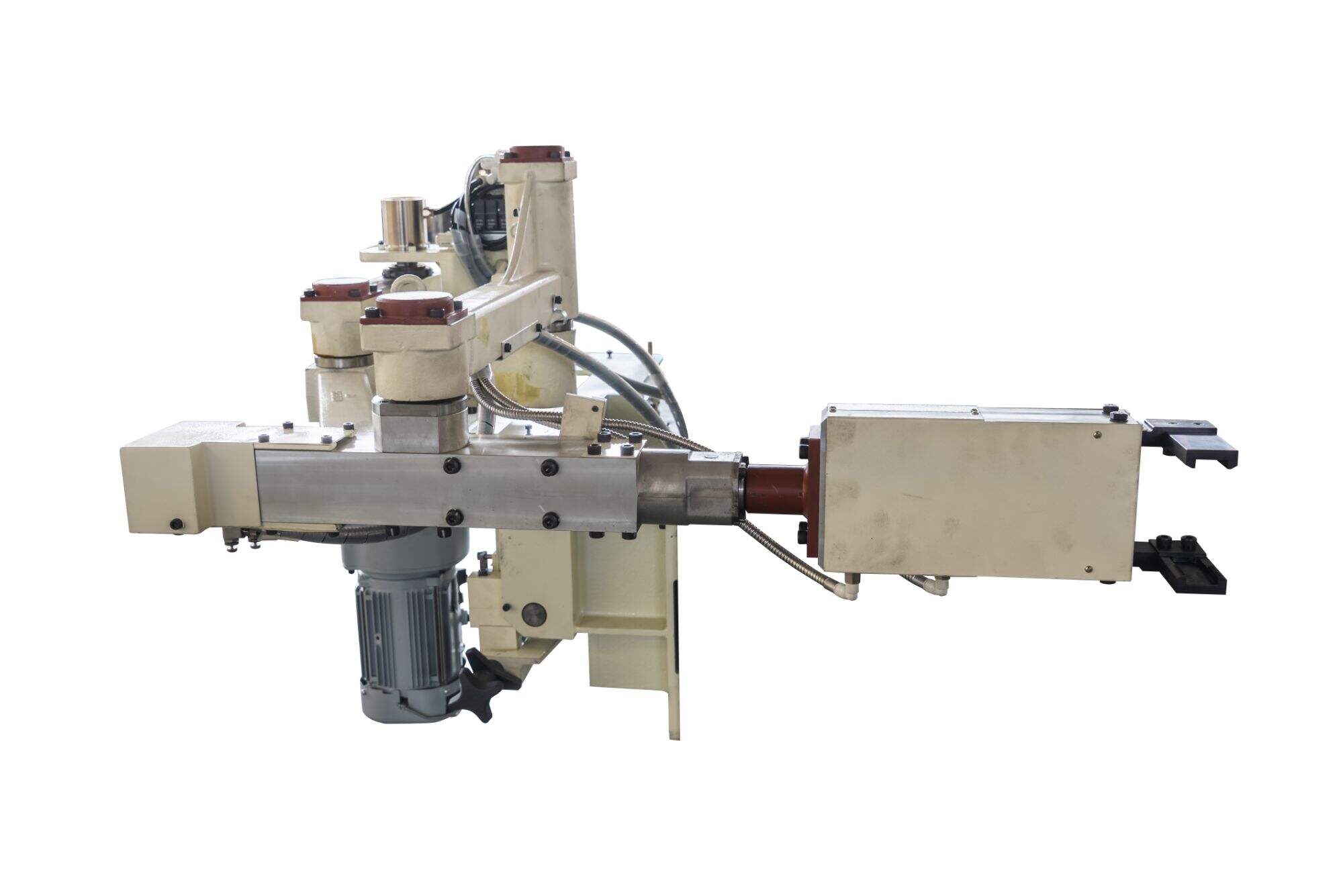

· Before carrying out maintenance work, isolate the Pingcheng vertical injection machine from the system.

· Keep the hydraulic system clean from contaminants that can cause leaks and low-pressure results.

· Make sure that your piston, bladder and valves are in good shape on every accumulator component.

· Avoid or at least minimize wear and contamination by using hydraulic oils and lubricants of high quality that meet the specific requirements to which they should comply within your system.

In hydraulic systems, industrial applications are plagued by pressure problems in the accumulators that cause system inefficiency and downtime. Troubleshooting the Pressure-related errors: The 1st action regarding solving pressure problems will be to discover just what is that triggers all of them and repair this.

A common problem with pressure related issues is having a faulty accumulator bladder or piston which both lead to low accumulator pressures. The defective part must be replaced to have the system up and running fully again. Finally, if the pressure problems result from large pressure drops that occur in a short distance such as those caused by oil control valves; examine whether this is occurring and replace hydraulic valve associated with these oil circuits visiting an application specialist to adjust the system - both (proportional) are options.

To sum up, Pingcheng vertical injection machine has a major impact on the efficiency of all that goes in our systems. Proper pressure management is essential to reduce downtime, improve system efficiency and prevent equipment failures. Following these precautionary measures and Best Practices as detailed above in this article, one could ensure the smooth operation of a system without any effect on hydraulic accumulator pressure industrial environment.

Pingcheng is Hydraulic accumulator pressure achieve their goals for business by providing our own supply chains and services solutions. We are focused on helping to extends the life and the values of your production. PingCheng could be the reliable supplier you requires. We are a trustworthy supplier who can offers you opportunities.

Pingcheng has at Hydraulic accumulator pressure and 50 technical employees who have experiences. They are committed providing tops quality. Mitsutoyo's measuring instruments and CMM are calibrated regularly. The double-checking keeps quality reliable and accurate. Each keys part traceable and controlled during machining and assembly.

Our customer services is Hydraulic accumulator pressure. For over a decades we've offered services for machining and developed a close cooperations with well-known Japanese companies. Pingcheng's adherence to truthful pricing is based on decades of experience and a deep understanding of this fields. When we receive a an inquiry for a quote, we review the drawings and simulations in our specialized software as soon as we can, and provides the most appropriate solution at an affordable prices.

Based on decades in experience and a deep understanding of the industry, Pingcheng is dedicated to offering customers a fair price. When we Hydraulic accumulator pressure, we examine the drawings and simulate using specialized software right away, and then provide the best solution for your price.