Have you ever seen a train on tracks and thought about how smoothly it moves? It’s pretty amazing! They have CNC rail which is a unique technology that supports trains to run smoother. It is disrupting the entire framework for thinking about transport and construction, to make things more efficiently

CNC is short for Computer Numerical Control. Computers assist in controlling how the rails are produced and machines' movement. Cool technology is used to create CNC rails, which helps heat accumulator machines move precisely where required. All trains in Ping Cheng are CNC rails that allow various parts to help a machine run in a better fashion in a timely manner. This allows us to build things more accurately and efficiently.

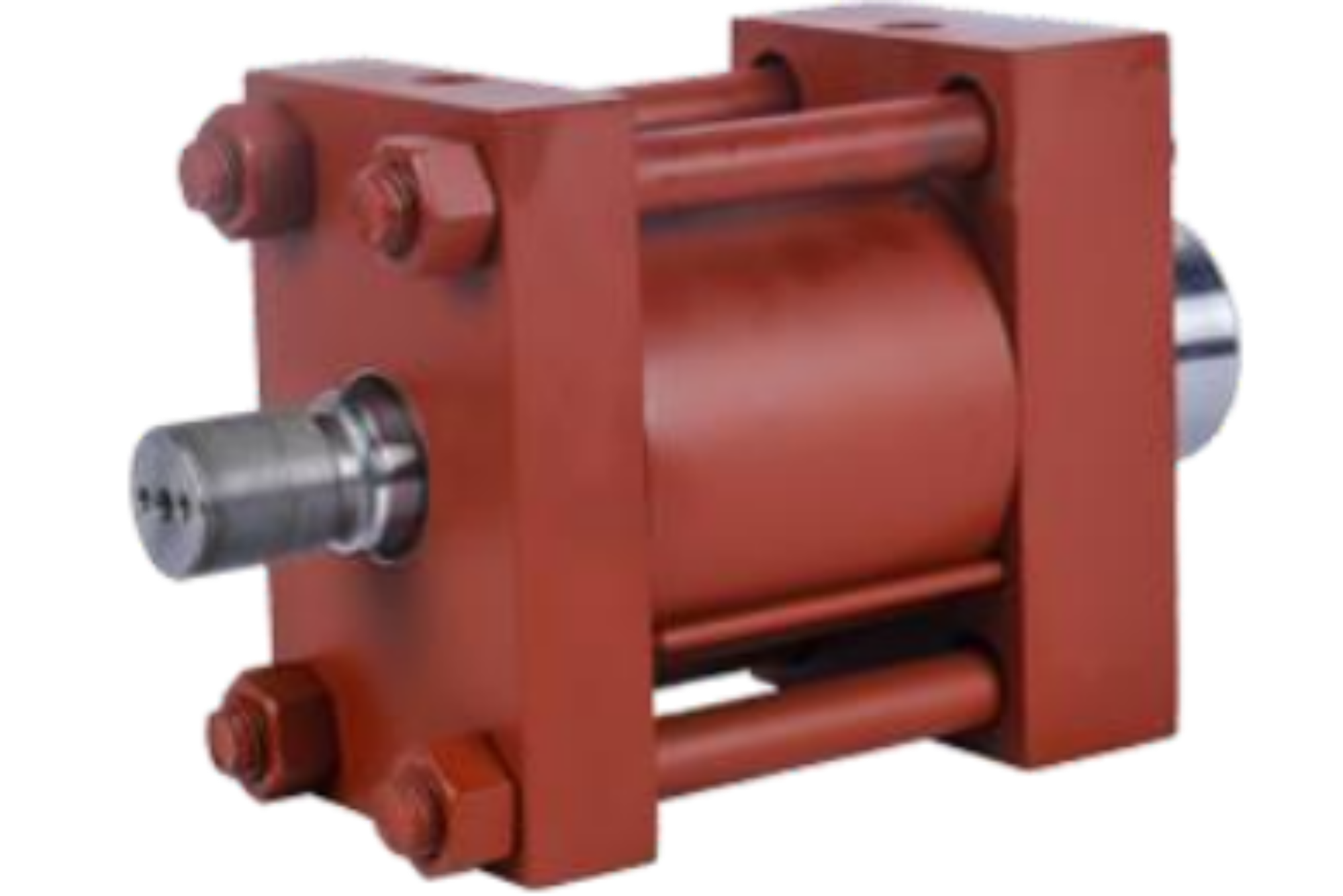

Well, CNC rails are revolutionizing production in factories and workshops. They speed up and refine the process. This technology helps machines to move in the right places without error. This enables us at Pingcheng to producing high-quality accumulator cylinder products to meet our customers' needs for the right fit. Using CNC rails also saves time and material, which is beneficial to everyone

Rail CNC technology is widely used in transportation and construction. In transportation, CNC rails are used to create the tracks that steer trains and others vehicles. The rails allow for safe passing and seamless functioning. They also keep cars from getting damaged while in motion, which is crucial for safety.

Get in Lean CNC rails form work is an important part of the construction process, aiding in constructing robust and sustainable structure. Thanks to this technology builders can now construct tall accumulator aircraft buildings such as skyscrapers withstanding various weather patterns while managing to last a lifetime. With CNC rails, we able to construct homes, schools and offices which are used by people on a daily basis.

The railroads are constantly evolving and changing. CNC, and new automation technology, allows us to make better parts for trains and other vehicles. These advances mean we can build rails that require less maintenance and last longer. This is amazing because it makes transportation and construction companies save time and money while remaining safe and reliable.

We aim to lead the industry in Pingcheng and continue innovating. With our latest technologies of CNC and automation investments, we can produce rail parts of world-class quality. It also helps us find ways to be less damaging to the environment, and also products that cost less for our customers.

Pingcheng has at Cnc rail and 50 technical employees who have experiences. They are committed providing tops quality. Mitsutoyo's measuring instruments and CMM are calibrated regularly. The double-checking keeps quality reliable and accurate. Each keys part traceable and controlled during machining and assembly.

Pingcheng a total process and lifecycle partners. The shipping of products is just beginning of our partnerships. Our customer service is all about ensuring your satisfactions. Since over 20 years we've provided machine-tooling services and established a strong partnerships with renowned Japanese firms. Our commitments to honesty in pricing is based upon our years experiences in the industry and our Cnc rail. We review drawing using special software and presents the best solutions at the most reasonable costs once we have received the request for quotations.

Pingcheng's Cnc rail and services are designed to helps customers meet their goals for business. We are focused on expanding and increasing the potential and lifespans of your productions. PingCheng is a dependable producers you are looking for. We are a suppliers that provides opportunities.

Pingcheng's Cnc rail is founded on decades of industry experience and a deep understanding. After we receive quotation requests, we examine the drawing and simulate in specialized software right away, and then provide the most effective solution with a fair price.