Ever wonder how your favorite toys, colorful cups and other plastic treasures are made? A great machine that we know from producing common-side walk things is the injection molding equipment. This is a process where that machine works by melting plastic then injecting it along with pressure in a mold to cool down and take shape. Conventional Injection Molding Machine Conventional injection molding machines use oil or gas which heat the plastic, while on electric injecting press uses electricity.

Introduction of Description electric injection molding machines are a revolution in manufacturing processes. These new ingenious machinery is efficient and was proved to produce more products in a lesser time that works on fast track mode. When companies are able to efficiently produce the things that people love they save money and can be more responsive to consumer preference.

In terms of sustainable manufacturing methods, the use of electric injection molding is a commendable option. These machines are part of a cleaner and healthier environment for all, as they use less energy and give off fewer pollutants.

While there are several advantages to electric injection molding, manufacturers still face certain difficulties. One thing to take care of, it should be clean because even a single drop or dirt can obstruct the production. It is also important to test the machine as well when it comes to proper calibration in order for one to heat up a plastic with uniform temperature if they want quality final products.

In the case of technology, innovation has been a crucial tool to drive progress in manufacturing. One of the most fascinating developments in this industry is 3D printing or creating molds for different and complicated shapes that can be applied to electric injection molding. In fact, robots have been found to be more efficient and accurate in the production process.

In summation, this advancement represents a groundbreaking manufacturing evolution electric injection molding machines. They do not only optimize the production cycle but also enhance sustainability by reducing energy and pollution. As with any new technology, electric injection molding has its own set of challenges which need to be addressed; but the potential for success and the never-ending evolution of ideas and technologies bodes well as it develops. An important teaching material in the future of manufacturing!

Pingcheng is dedicated to helping customers electric injection by providing our supply chains and services solutions. We strives to help you extends and maximize the life and worth of your products. PingCheng is the reliable manufacturers you're looking for. We are a company that delivers potential.

Based on decades of experience and electric injection, Pingcheng is dedicated to providing its customers with a fair price. We examine the drawing, model it with specialized software and then give you the most affordable price.

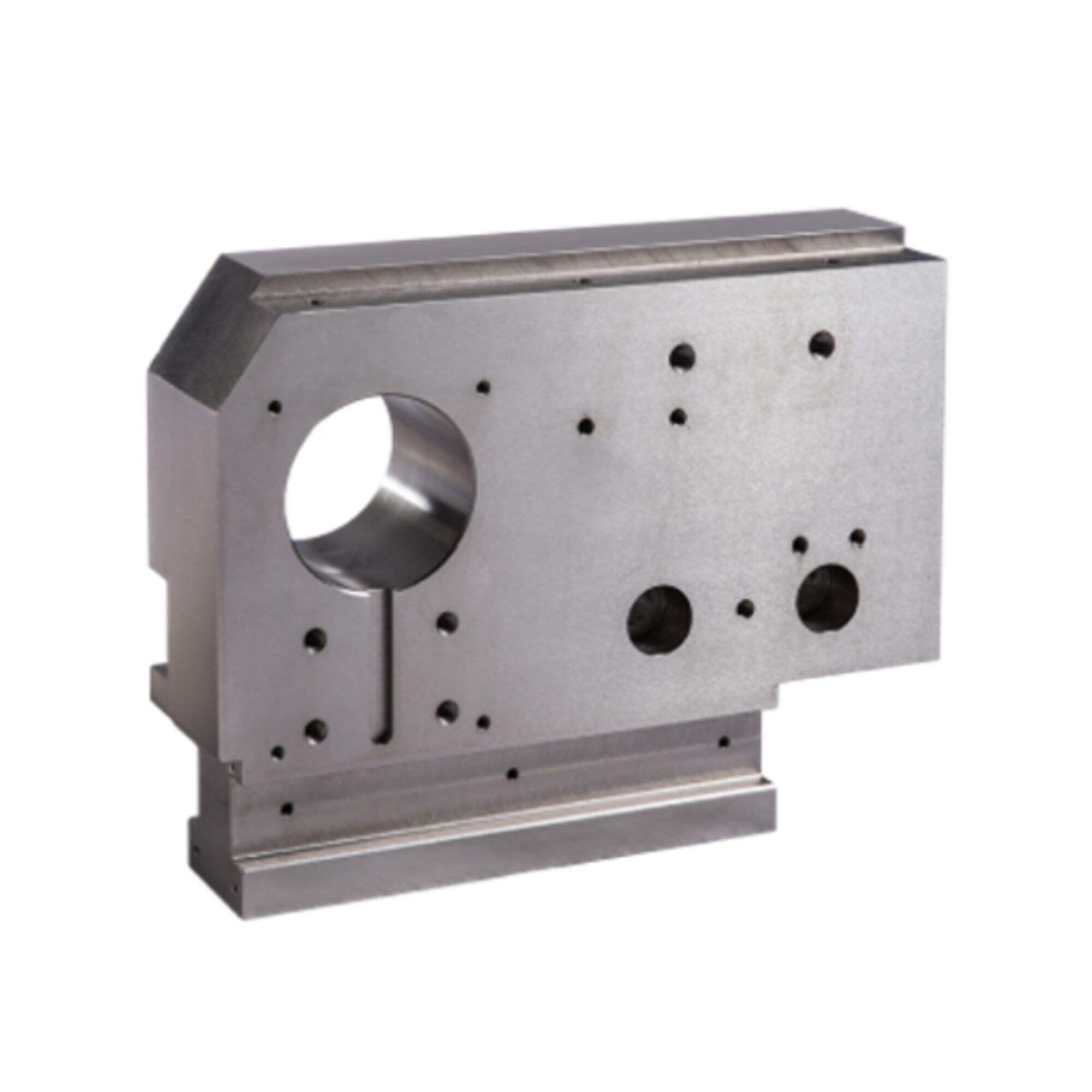

Pingcheng currently has more than 20 manufacturing facilities and 50 highly skilled technical employees. They electric injection. Mitsutoyo's measuring instruments and CMM are periodically calibrated. The double-checking keeps our quality steady and accurate. The machining and assembly of all key parts are tracked and controlled.

Our customer services focuses your satisfaction. We've been providing the machining services and electric injection with industry-renowned Japanese businesses for more than 20 years. Based on decades experience and knowledge of this industry, Pingcheng is dedicated to giving customers honest prices. Once we get a quotation requests, we look at the drawings and simulates using specialized software immediately, and offer the best solution with proper prices.