CNC machining is a method of creating objects using a computer which drives a specialized machine, along with Pingcheng's product multiplas vertical injection molding machine. The machine is called the CNC machine. Each CNC machine has several tools to cut, shape, and drill parts from different materials.

Somewhat of CNC machining has lots of benefits for high-tech preparation, identical to gear box for wind turbine from Pingcheng. Among the most significant benefits is the ability to produce intricate components that would be extremely challenging — if not impossible — to manufacture through conventional means.

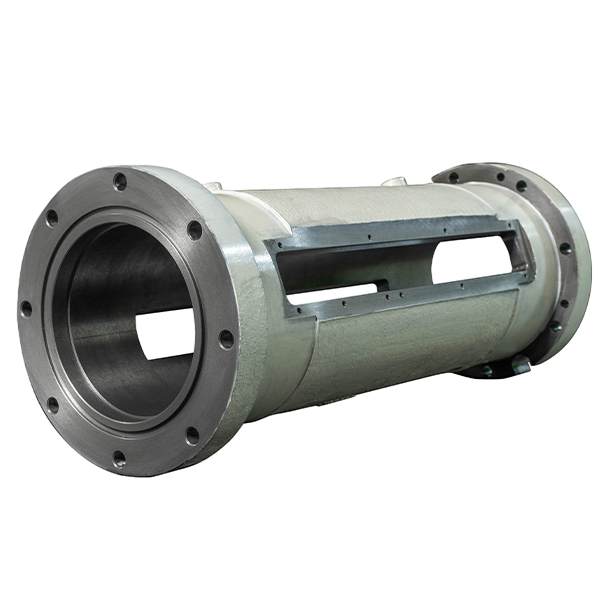

Additionally, CNC machines can create a lot of parts with a high level of consistency, same with Pingcheng's 100 ton cylinder. That means all parts are manufactured in the same way, each time. This is particularly critical in sectors such as automotive manufacturing, where components must be produced precisely to ensure proper functioning.

An example of this is a CNC machine with a robot arm that loads/unloads the parts from the machine, also the high pressure hydraulic accumulator developed by Pingcheng. Automation also makes the process faster and safer by decreasing human operator requirement.

Consider a business that needs larger parts – maybe a CNC machine with a wider working space and multiple cutting tools would be the right fit, identical to Pingcheng's product high pressure die casting suppliers. In contrast, if a company focuses on small, intricate parts, they would require a CNC machine highly accurate and features a smaller workspace.

Pingcheng is dedicated to helping customers Part cnc by providing our supply chains and services solutions. We strives to help you extends and maximize the life and worth of your products. PingCheng is the reliable manufacturers you're looking for. We are a company that delivers potential.

Based on Part cnc and a deeps understanding of the business, Pingcheng dedicated to providing its customers with a fair prices. When we receives a an inquiry for quotes, we look at the drawings and simulates using special software immediately, and offer the most effective solutions with a fair costs.

Our customer services is Part cnc. For over a decades we've offered services for machining and developed a close cooperations with well-known Japanese companies. Pingcheng's adherence to truthful pricing is based on decades of experience and a deep understanding of this fields. When we receive a an inquiry for a quote, we review the drawings and simulations in our specialized software as soon as we can, and provides the most appropriate solution at an affordable prices.

Pingcheng now Part cnc and 50 technical staff with years of experience. They aim at providing high quality. They then inspect the products by Mitsutoyo measuring instruments and CMM that are periodically calibrated. Double-checking makes sure that the product's quality precise and steady. The machining and assembling of all important parts is monitored and traceable.