Ever listened about high precision die casting? This is a unique method to manufacture your metal parts. So what we do in this process is that hot metal which is melted or liquid means it is not hardened so you will understand and then poured into the shape with called mold. The mold, in this case, can be thought of as a two part interlocking container. The metal will melt, and once it is poured into a mould to cool off or solidify. Once the metal has cooled and solidified, those parts are carefully extracted from the mold and tidied up to remove any extraneous bits. It takes great skill to manufacture parts in this way. There have to be a lot of attention and meticulous detail at its finest, performed by the worker so it all gets set up just around right.

High precision die casting allows you to create the most exact, thinnest parts. These are made with great precision to provide the parts of high quality. They are able to precision craft the parts and with such a low margin of error, these finished components will be very reliable. When you install these parts, then it provides maximum functionality and gives stable performance every time. This is concerning for a software intended to be used in situations where safety and security are paramount.

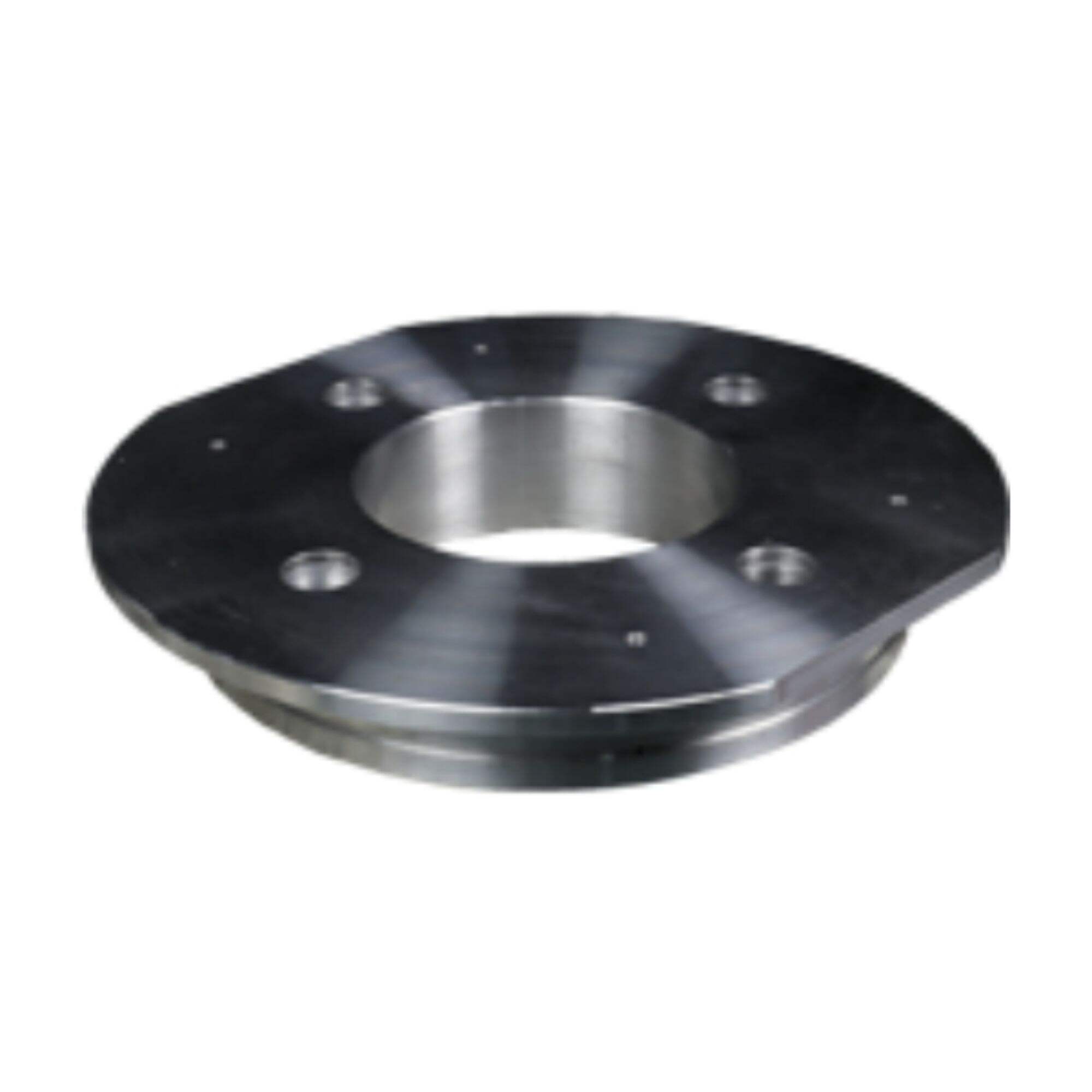

One of the greatest advantages of high precision die casting is that the components this manner produces are extraordinarily robust. These molds are made in a way that it can produce parts which will not shatter under high forces applied to them. That makes it useful the countless applications where strength is required, including vehicles and machinery. If a part is strong and durable, it can last ages even in extreme conditions- ultimately saving you money by reducing the need for replacements.

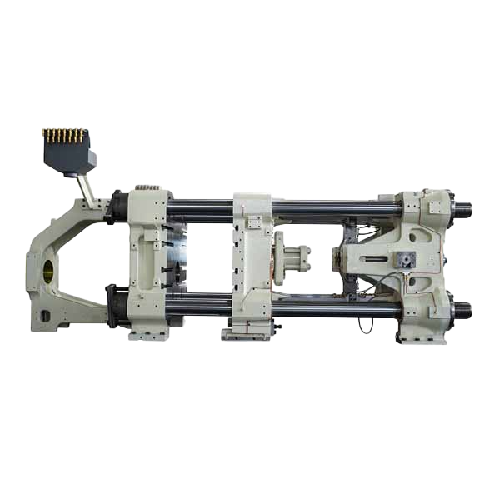

High precision die casting is a speedy process as well, which means less money and time spent in the production of parts. The molds help in fast part production and it helps companies to produce parts on a very large scale in shorter period. This is of course essential for those companies who are processing large product runs on tight deadlines. High precision die casting makes high quality parts quickly, helping companies to fulfill orders and keep their customers happy.

High precision die casting advances due to its capacity for effortlessly manufacturing complicated shapes. The molds created with this process are able to make parts that have a lot of fine, detailed work which is important for lots of applications. This allows not only for parts with extremely thin walls, but also geometry that can be impossible — or at least very difficult to build from other manufacturing methods. This adaptability makes high precision die casting an essential solution to a range of applications and various businesses.

Pingcheng is a high precision die casting and lifecycle partners. The shipping of our products is only the beginning of our partnerships. Our customer services is about ensuring your satisfaction. Since more than 20 years ago, we have offered manufacturing services and have built a closed collaboration with well-known Japanese firms. Pingcheng's dedications to fair pricing is based upon our years of experiences and understanding of this sector. We analyze the drawing in an advanced software program and then provides the most efficient solution at the most reasonable cost once we have received the requests for quotation.

Pingcheng's commitment for honest pricing is founded on years of experience in the industry and knowledge. After we receive the request for quote, we review the drawings and simulate high precision die casting as soon as we can, and provide the best solution for your cost.

Pingcheng is committed to helping customers achieves their business goals through our high precision die casting and service solutions. We concentrates on helping you extend the life and values of your production. PingCheng is the dependable manufacturers you're looking for. We are a company that delivers options.

Pingcheng is now home to more than 20 manufacturing facilities and 50 experienced technical workers. They high precision die casting. Then, the product is inspected by Mitsutoyo measuring instruments and CMM that are periodically calibrated. Double-checking makes sure that the quality of our products precise and steady. The machining and assembly of all the key components are controlled and traceable.