DIY stands for "do-it-yourself. “It’s a fun way to just start DIY-ing things at home. Homemade CNC mill: if you're a tool user, you've probably told yourself you need a CNC mill, if you don't already have one. This is a special kind of machine that you can use to make precision cuts and designs in a workshop setting. If you want to find out more about how to build this great tool for you, read on! We will also show you how to make your own cnc mill by step.

A CNC mill is a machine that allows you to fit and designs various materials with extreme precision. It is a versatile tool that can cut through various materials like wood, plastic, and even metal! You can thus make whatever design you like, be it one that is elaborate and complex or one that is simple and easy. Building your own CNC mill means you can make your own custom builds within the comfort of your own home! You may create your toys as well as some models and certainly can make useful items for your house. Yes, the possibilities are endless!

If you have a workshop and enjoy building and planning projects, adding a DIY CNC mill to your collection can radically elevate your productivity. This machine is used for creating precise cuts and designs in various materials, including wood, plastic, and metal. You will be able to take on unique jobs and be able to design things specific to whatever you are working on, enabling you to start some really unique projects. It would amazing to be able to print your own furniture or be able create artistic pieces in your o patent!

So, now you know what a CNC mill is and what you can do with one, time to get started building! If you want to build your own put your skill to the test with an open source CNC mill project. In order to do this project well you need at least a basic understanding of the tools and materials you will be using. This is to say you shouldn’t be afraid of using things like saws and drills. Building the CNC mill will take time and patience, but the results will be very gratifying!

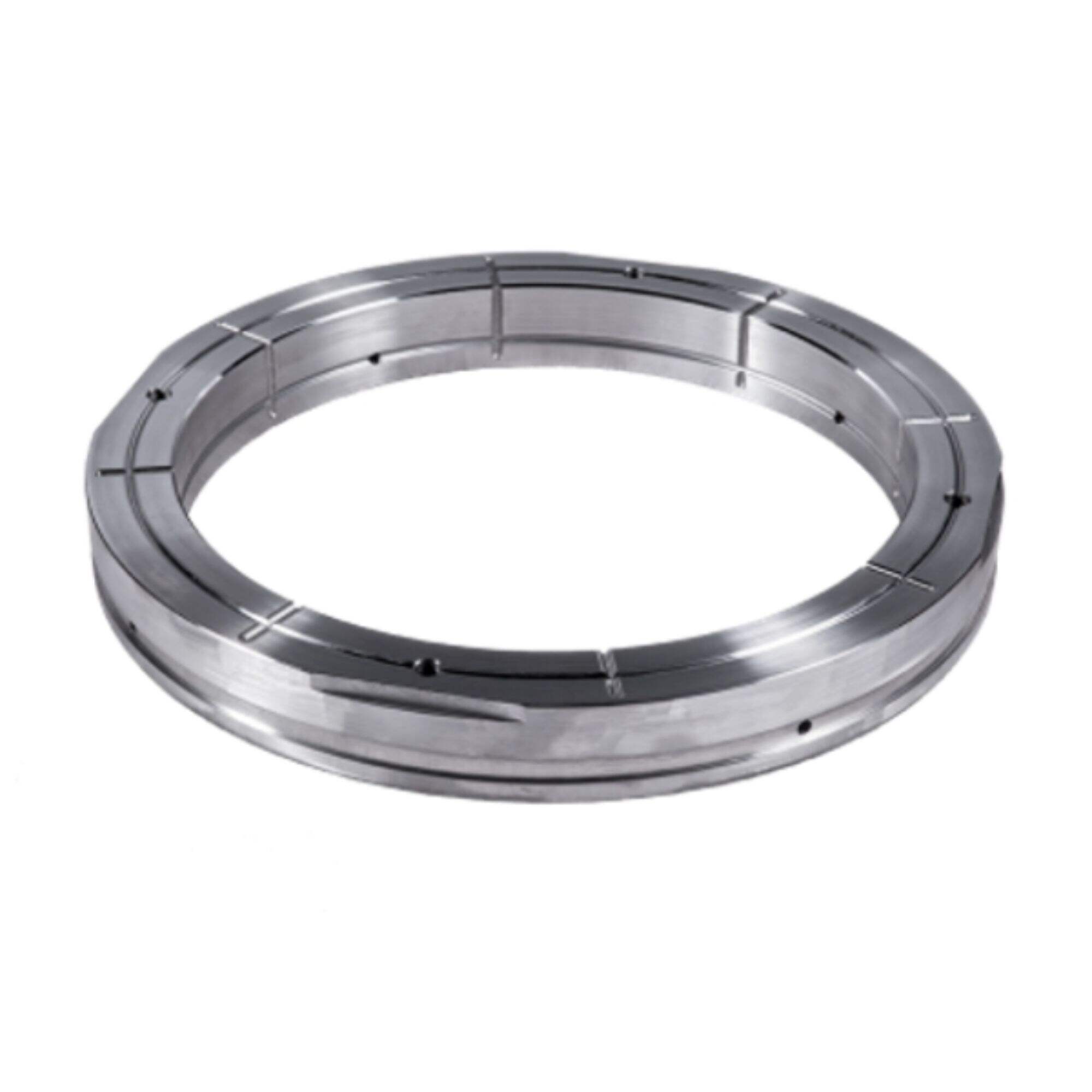

You will need some tools and materials for building your own CNC Mill at your home. You'll just need to gather some things: Aluminum sheets, steel plate, ball bearings, stepper motors, screws, etc. You'll also need a computer to run the CNC program to control the Machine. If you are in pausing on where to find these electronics or tools, you can search the internet for guides that can help you with your CNC mill building process.

Lastly, verify that everything works by sampling the CNC mill. So you want to make sure you have everything configured correctly before you use it.

It takes a little work and know-how to build your own CNC mill, but it's a fun project. Once you build it, its just gonna be there for you to use when building whatever comes to your mind. You can create new toys, tools, decorations for your home, etc.

With years in experience and a home made cnc mill, Pingcheng is dedicated to providing customers with honest price. When we receive a the request for quote, we review the drawings and simulates using special software right away, and then provide the most effective solution with a fair price.

The supply chains and services of Pingcheng are home made cnc mill achieves their business goals. We concentrates on extending and maximizing the values and life of your production. PingCheng is a dependable manufacturer that you're looking for. We are a reliable partners that can provide opportunities.

Pingcheng is a full-service and home made cnc mill. The shipping of our products is just the beginning of our partnership. Our customer service about ensuring your satisfactions. For more than 20 years we've provided manufacturing services and have built close collaboration with well-known Japanese companies. Pingcheng's adherence to truthful pricing is based our decades of experiences in the industry and understanding this sector. We analyze the drawing in special software and present the best solution at an affordable costs once we have received an inquiry for quote.

Pingcheng now home made cnc mill and 50 technical staff with years of experience. They aim at providing high quality. They then inspect the products by Mitsutoyo measuring instruments and CMM that are periodically calibrated. Double-checking makes sure that the product's quality precise and steady. The machining and assembling of all important parts is monitored and traceable.