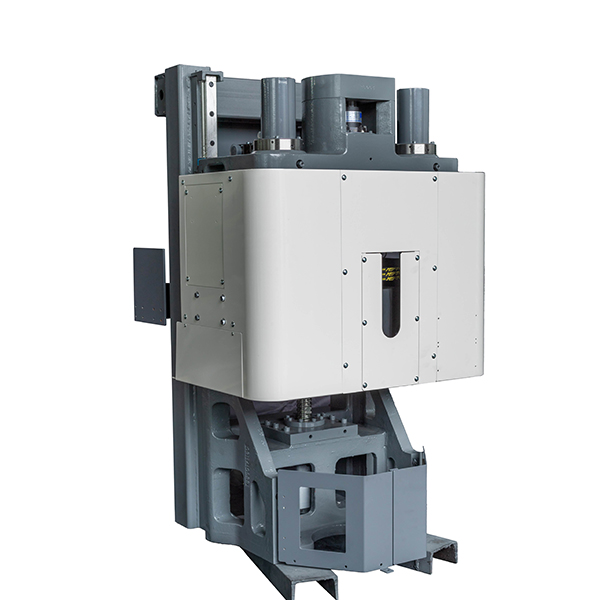

So, let's get started with one of most exciting machines in the world Hydraulic moulding machine which is so common in factories but has a vital role to play when it comes to manufacturing several items from car parts, toys etc. They work by using the power of hydraulic pressure - similar to strong water force - to shape materials such as plastic or metal into particular shapes. But this is precisely why the technology impresses: how well it can control pressure and make something that looks exactly like what someone designed.

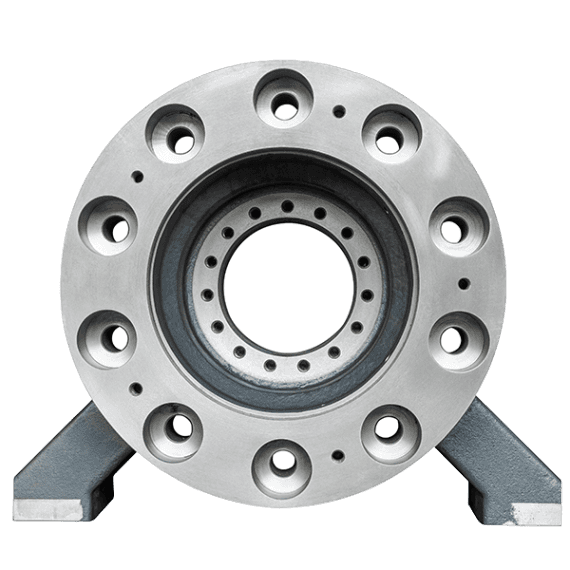

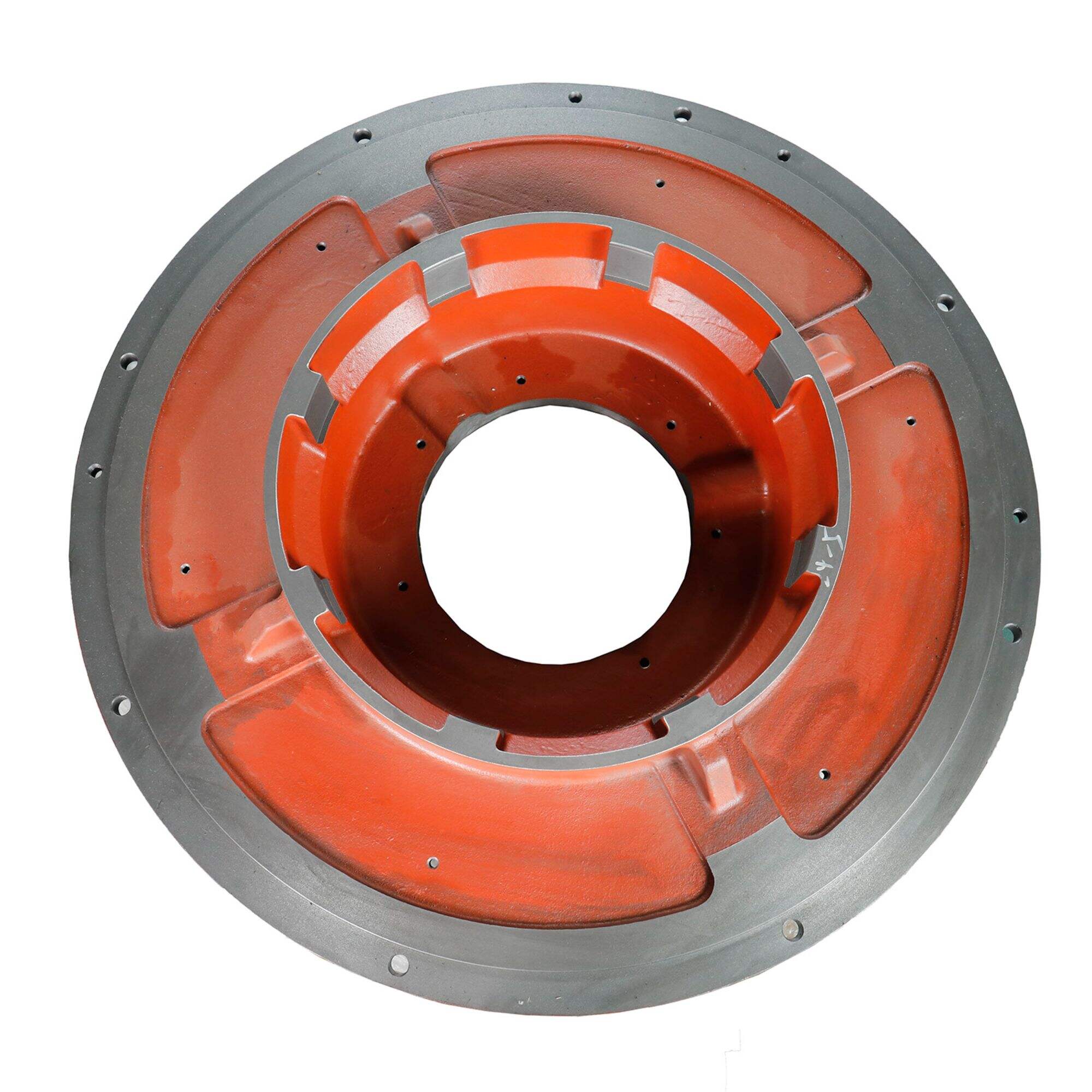

The ability to produce high volume output is one of the most conspicuous advantages that hydraulic molding machines have. This starts with the heating of some material, plastic pellets or metal powder, to a state where it is malleable. From there, the material is then placed in a this specialized mold as a metal puzzle piece of sorts perfectly carved out to be what you are making; While the mold surrounds and fits tightly around this material, pressure from hydraulics within is used to compress it into the form of said mold. Opening the mold up and you have a finished product that is ready to use.

A number of review particular features are common on these machines, all in the name to protect output quality as much as possible. You can finely adjust the pressure to exactly what you need for exact molding of material. Secondly the machines can be programmed to a perfect temperature and pressure setting for each specific material helping create consistency in production. Finally, the molds themselves are produced with high precision so that products look exactly like their design.

Hydraulic molding machines are easily the most cost-effective solution for production. The same mold can be used over and over, reducing the cost associated with establishing new molds containing different items. Moreover, the machines are quick on their feet and allow an immediate production that ultimately results in a fast selling of the product which eventually improves efficiency.

There are a number of reasons why Hydraulic molding machines serve such an important function in the production lines of just about every modern product around. In the ability to quickly and accurately produce goods, factories allow for mass production capability of customer requirements. Besides, their performance is consistently at a high level which assured customer satisfaction and devotion. The hydraulic molding machines, in addition being cost-effective helps enterprises to save money and stay competitive with those device.

At the end of the day, hydraulic plastics machines are a significant advancement in technologies for fast and accurate low-cost production and manufacturing numerous products. The importance of this form in contemporary production is obvious: it sustenance the creation of multitude objects we use on a daily base.

Our customers service focuses your satisfaction. We've been providing machining services and hydraulic molding machine with industry-renowned Japanese companies for more 20 years. Based on years of experiences and knowledge of the industry, Pingcheng is dedicated to offering our customers an honest price. We evaluates the drawings using special software and present the best solutions at the most reasonable costs once we have received requests for quotations.

Pingcheng has now more than 20 manufacturing machines and hydraulic molding machine with years of experience. They aim at providing high quality. They then inspect the products by Mitsutoyo measuring tools and CMM that are calibrated on a periodic basis. Double-checking ensures that the product's quality precise and steady. Every key component is traceable and controlled during the machining process and assembly.

Pingcheng's commitment for honest pricing is based on its years of experience in the industry and a deep understanding. We hydraulic molding machine, recreate it in specialized software, and then provide the most competitive price.

The supply chain and services of Pingcheng are designed to help clients achieve their goals in business. We concentrate on extending and increasing the potential and lifespan of your manufacturing. PingCheng is a hydraulic molding machine you've been searching for. We are a partner which delivers opportunities.