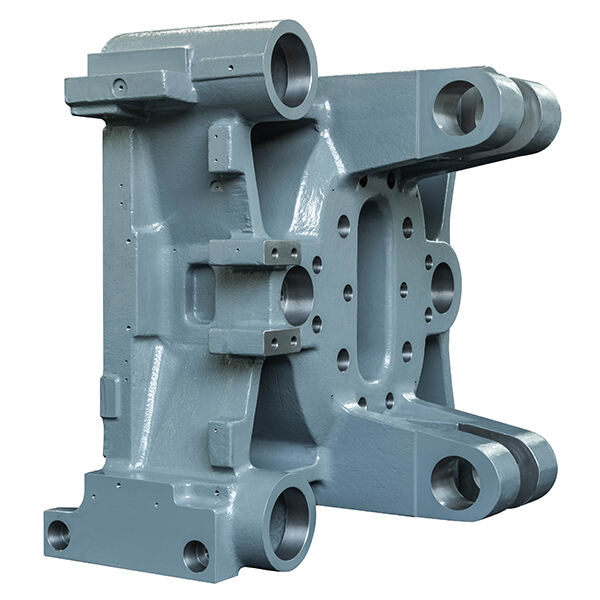

Mobile/dsk2-samplesWhen we need to manufacture parts that are strong and lightweight, one of the methods used is high vacuum die casting. It is a method to produce parts by pouring metal in molten state into the mold after also making vacuum, which is clever thinking. Our job is to assist the metal in order to fill that mold completely and all correctly, by sucking out the air. This means we could build parts that are very high quality, and repeated (the same each time).

Waster is a major problem with regular die casting. At times, due to the few gas pockets inside mold some of the metal gets wasted. This trapped air is able to create faults or issues on the parts we are attempting to produce. In high vacuum die casting the metal fills out the mold in a more complete manner leading to higher yields and less melting down of good partsание. This also leads to better aesthetics and stronger parts compared to regular manufacturing techniques. The end products come out of such machines, with better finish and minimal or no holes that make them more dependable.

The high vacuum die casting is a good choice as it creates parts which are strong, ensure that the strength of produced castings increases following heat treatment and yet remains light-weight. One of the main aspects that find a reduction in this process is, air and gas are trapped inside whereas here hardly any amount remains trapped due to its vigorous agitation. The finished part is lighter because there is less air and gas. Products made with this method are durable and can be use in every way such as automotive, electronics using everyday even up to a medical devices. And hence the high vacuum die casting can be said to a most versatile.

There are several reasons to why using high vacuum die casting is the sensible option. For starters, it is a lot more precise than typical die casting which means we can presume the parts will be exactly how we want them to be. Secondly, it can save us money by reducing the waste and getting a good end product. The quality and texture of the parts created this way are superior. This also gives us the ability to design more intricate shapes or features that may be too challenging, if not impossible with other methods. A designers and engineers dream.

High vacuum die casting is widely used in all walks of life. One common use case today is the automotive industry where it can be used to fabricate car parts, which require high strength and low weight. Its also used in medical tools because it is very precise and reliable. Applications that further benefit from this approach include marine applications, which need parts that can endure the harshest of elements and aerospace components in a lighter design for flight. For this fact, vacuum die casting is the preferred choice in many of these applications due to fast and accurate production for lightweight parts.

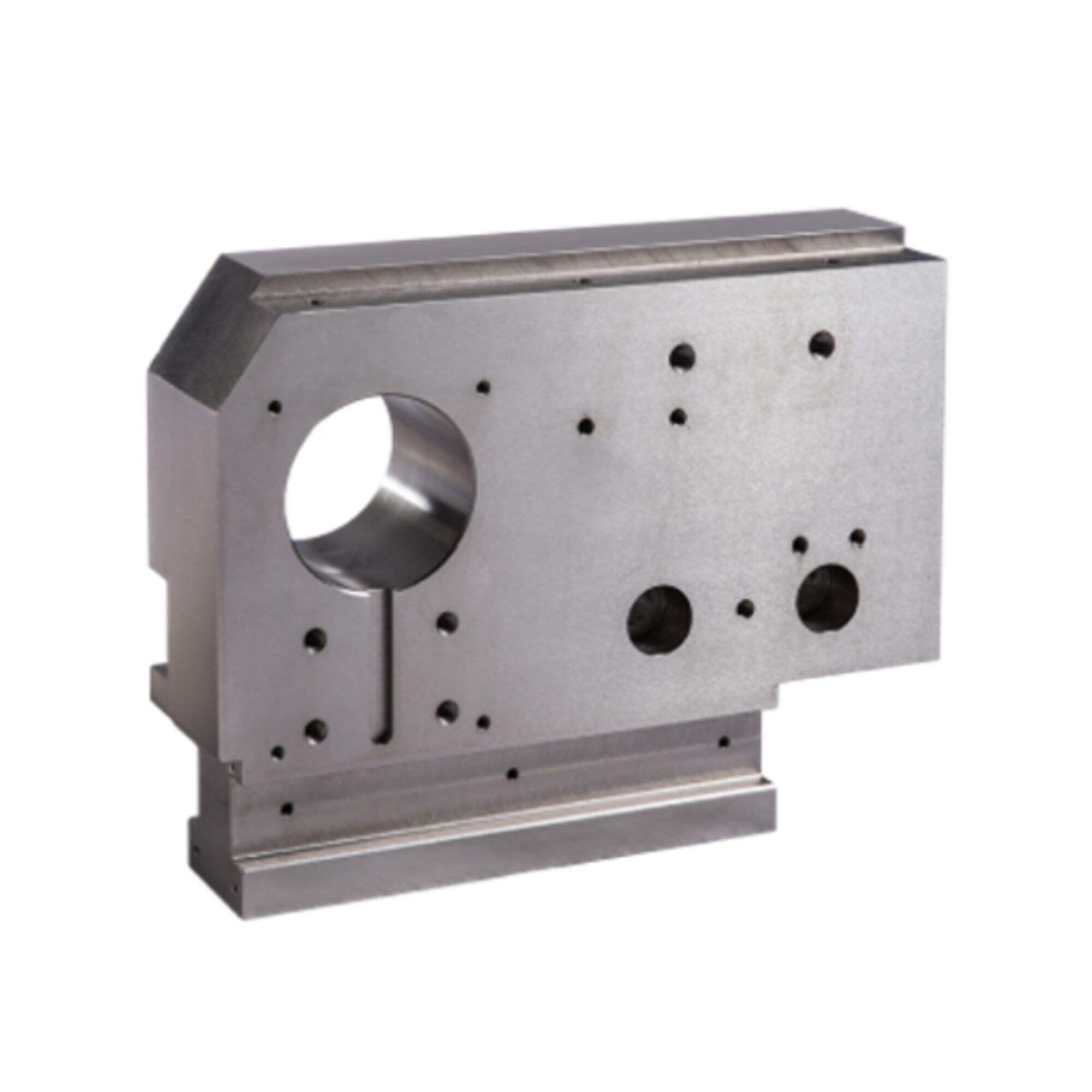

Pingcheng is now high vacuum die casting and 50 highly skilled technical employees. They committed to providing highest quality. Mitsutoyo's measuring instruments and CMM are calibrated regularly. The double-checking keeps quality reliable and accurate. The machining and assembling of all keys components are easily traceable and controlled.

Pingcheng is dedicated to helping customers high vacuum die casting by providing our supply chains and services solutions. We strives to help you extends and maximize the life and worth of your products. PingCheng is the reliable manufacturers you're looking for. We are a company that delivers potential.

Pingcheng's commitment for honest pricing is founded on years of experience in the industry and knowledge. After we receive the request for quote, we review the drawings and simulate high vacuum die casting as soon as we can, and provide the best solution for your cost.

Pingcheng is a high vacuum die casting and lifecycle partners. The shipping of our products is only the beginning of our partnerships. Our customer services is about ensuring your satisfaction. Since more than 20 years ago, we have offered manufacturing services and have built a closed collaboration with well-known Japanese firms. Pingcheng's dedications to fair pricing is based upon our years of experiences and understanding of this sector. We analyze the drawing in an advanced software program and then provides the most efficient solution at the most reasonable cost once we have received the requests for quotation.