For example, think about everything we see and use on a daily basis that is made of metal. Metal is quite important resource which widely used in a plenty of everyday items. For example, it is used in cars that drive on the road, bikes we ride for fun or exercise and pots and pans you cook with; even in parts of buildings where we live & work. High pressure die casting is a remarkable method to manufacture metal components, and in fact today nearly all of the metallic items we use are probably created through this very technique.

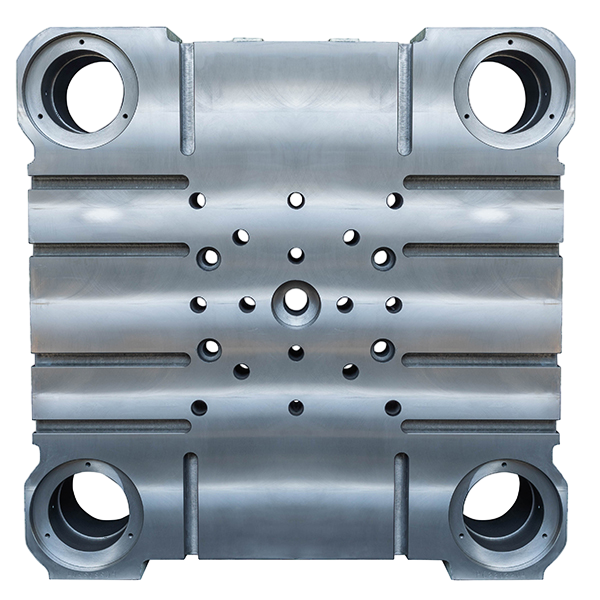

So how does high pressure die casting work, simply spoken the liquid metal is pushed into a mold at gigantic amounts of pressures. Imagine a big squeeze! It solidifies when the metal fills up in a mold and cools down. It is typically employed to make small and mid-sized parts that require unique shapes or designs. High pressure die casting is so popular since it creates parts that are both strong and long lasting, allowing for a high level of use without breaking.

Needless to say, if you are fabricating metal parts, it´s crucial that every part functions correctly and looks the same. When the need is for parts which are very accurate and nearly equal, high pressure die casting process prove to be a preferred solution. This leads to identical-looking pieces, similar to those on a lego model that ensure for simple assembly in larger products. If you're building a machine, parts that fit together nicely can greatly ease your task and guarantee everything works optimally.

Another thing that makes high pressure die casting beneficial is its capability of producing a wide variety of shapes and sizes. The molds in this technique are also highly robust and long-lasting. They can fabricate tens-of-thousands of parts before needing to be replaced, that is very cost efficient for manufacturers. This versatility has since established high pressure die casting among the many industries such as automotive, aerospace to defense in which products ranging from small parts up to complete systems are designed and developed.

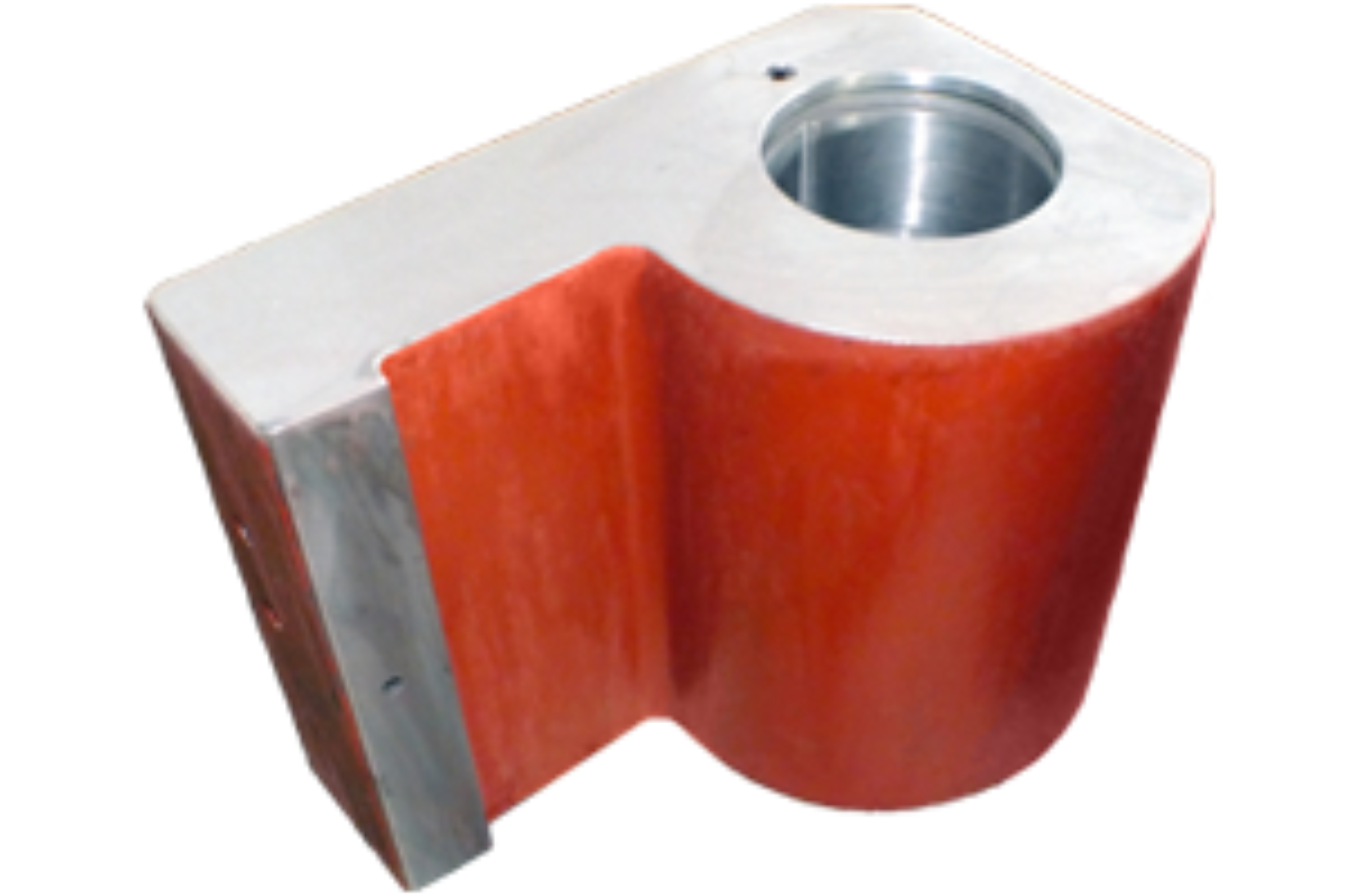

Metal products often suffer much stress and pressure from such processing operations. The high-pressure die casting parts are specially designed to be very firm and can withstand the pressure for much longer without breaking it in between. This feature is essential for components used in cars, bikes and similar products that require trustworthiness and security. A weak or strong part can be the difference between running correctly and potentially catastrophic failure.

Metal part fabrication involves painstaking attention to detail. Step 1: The castings of high pressure die casting parts have to undergo through various quality checks, in which checking sizing and shape is a part of it. This makes certain that everything corresponds with the way it ended. Moreover, quality metal is needed to design these parts so they do not become wear and break down over time. Manufactures are concerned about quality control to ensure each part is the highest of quality.

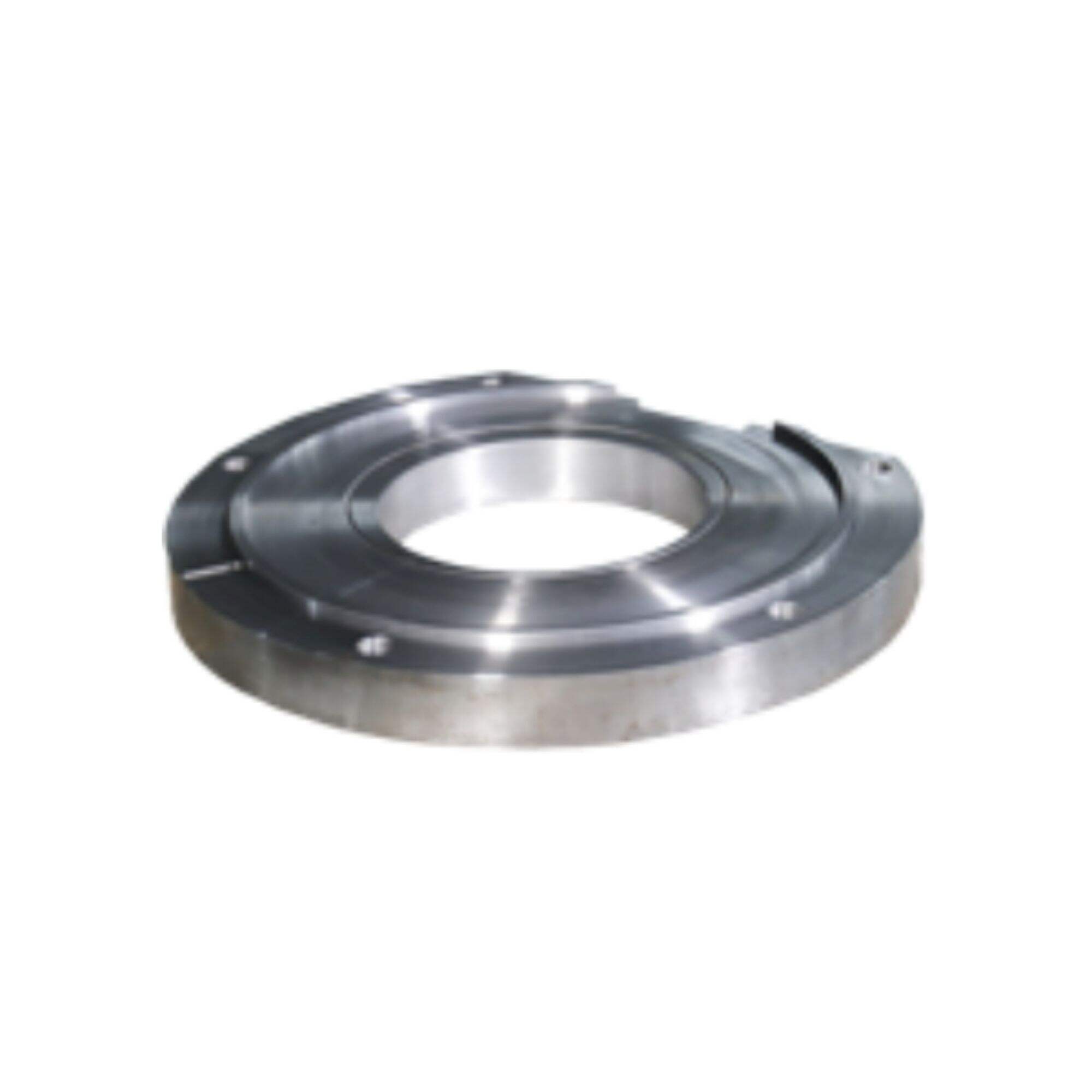

Pingcheng now high pressure die casting components and 50 technical staff with years of experience. They aim at providing high quality. They then inspect the products by Mitsutoyo measuring instruments and CMM that are periodically calibrated. Double-checking makes sure that the product's quality precise and steady. The machining and assembling of all important parts is monitored and traceable.

The supply chain and services of Pingcheng is designed to assist customers reach their business goals. We focus on extending and high pressure die casting components. PingCheng is the reliable manufacturer you're looking for. We are a partner which delivers options.

Pingcheng is a full-service and high pressure die casting components. The shipping of our products is just the beginning of our partnership. Our customer service about ensuring your satisfactions. For more than 20 years we've provided manufacturing services and have built close collaboration with well-known Japanese companies. Pingcheng's adherence to truthful pricing is based our decades of experiences in the industry and understanding this sector. We analyze the drawing in special software and present the best solution at an affordable costs once we have received an inquiry for quote.

Pingcheng's high pressure die casting components is based on decades of industry experience and understanding. We review the drawing, model it using specialized software and then provide the most competitive price.