Например, подумайте обо всем, что мы видим и используем ежедневно, сделанном из металла. Металл является весьма важным ресурсом, который широко применяется во множестве повседневных предметов. Например, он используется в автомобилях, которые ездят по дорогам, велосипедах, на которых мы катаемся для развлечения или спорта, и в кастрюлях и сковородках, которыми вы пользуетесь для приготовления пищи; даже в частях зданий, где мы живем и работаем. Высоконапорное литье под давлением — это замечательный метод производства металлических деталей, и на самом деле сегодня почти все металлические изделия, которые мы используем, вероятно, созданы именно этим способом.

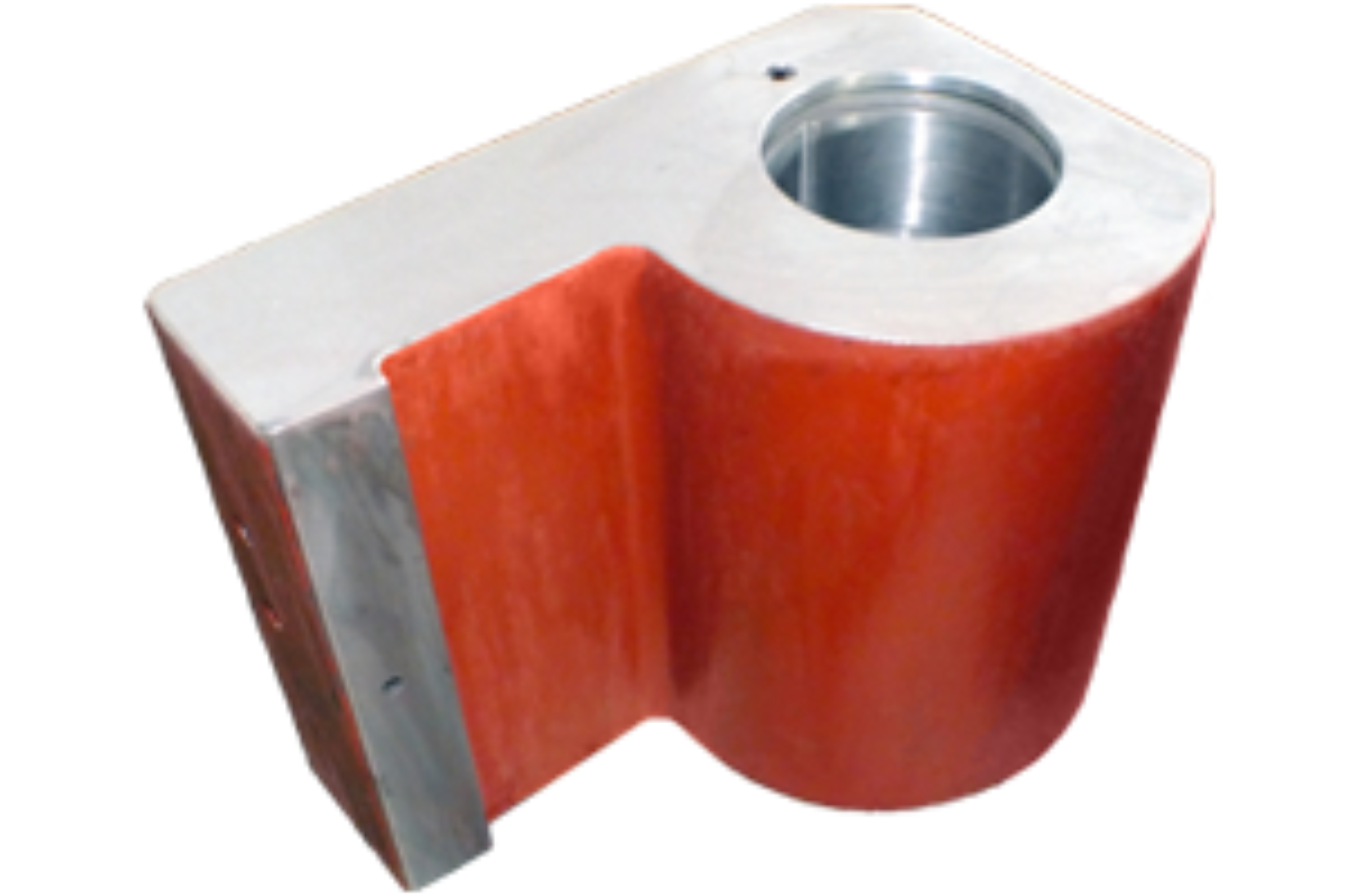

Итак, как работает высокотемпературная штамповка под давлением? Простыми словами, жидкий металл впрыскивается в форму под огромным давлением. Представьте большую сжатию! Он затвердевает, когда металл заполняет форму и остывает. Этот метод обычно используется для производства маленьких и средних деталей, которым требуются уникальные формы или дизайны. Высокотемпературная штамповка под давлением так популярна, потому что она создает детали, которые прочные и долговечные, позволяя использовать их на высоком уровне без поломок.

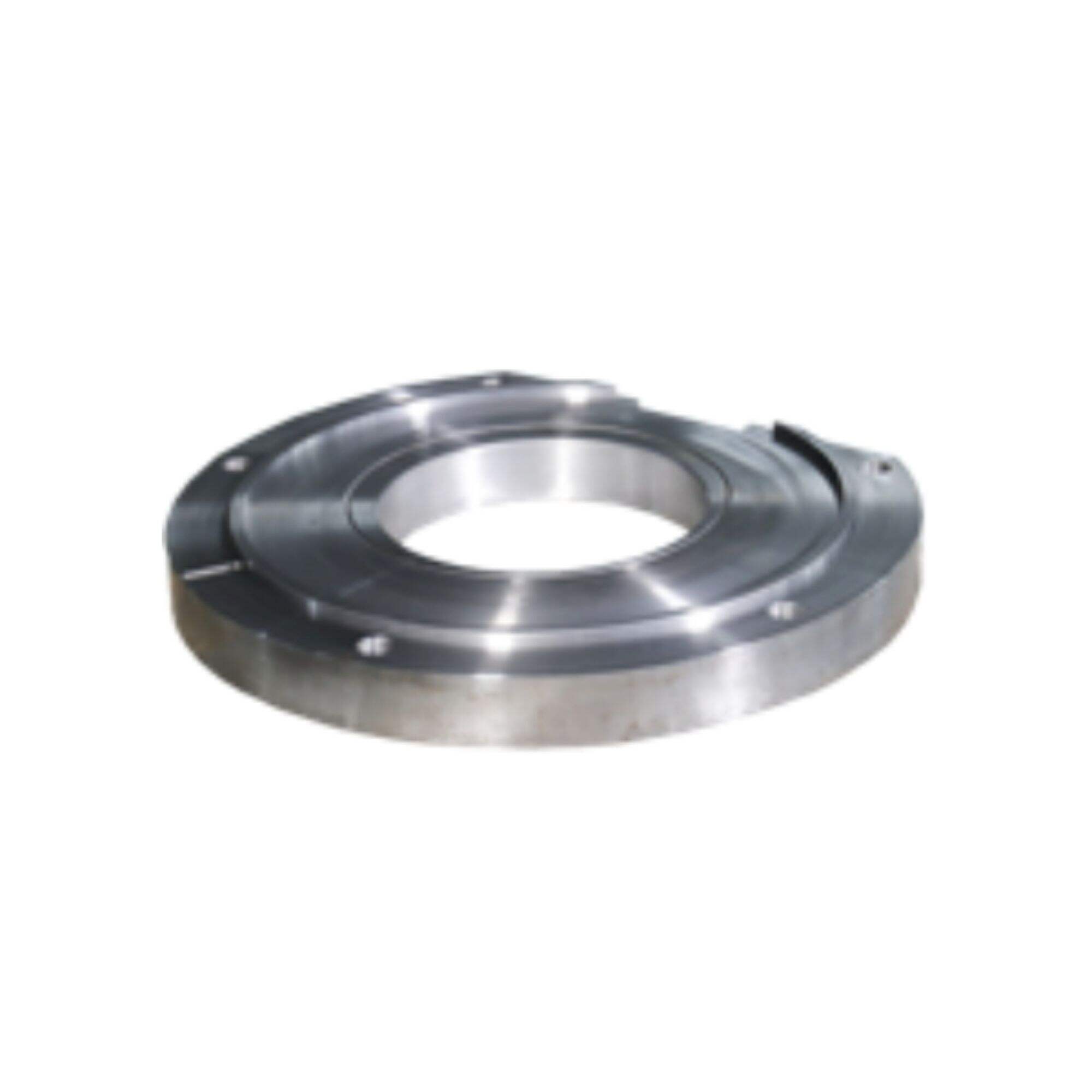

Безусловно, если вы изготавливаете металлические детали, крайне важно, чтобы каждая деталь работала правильно и выглядела одинаково. Когда требуется высокая точность и практически идентичные детали, процесс литья под высоким давлением становится предпочтительным решением. Это приводит к деталям с одинаковым внешним видом, похожим на элементы конструктора лего, что обеспечивает простую сборку в более крупных продуктах. Если вы собираете машину, детали, которые хорошо подходят друг к другу, могут значительно облегчить вашу задачу и гарантировать оптимальную работу всего механизма.

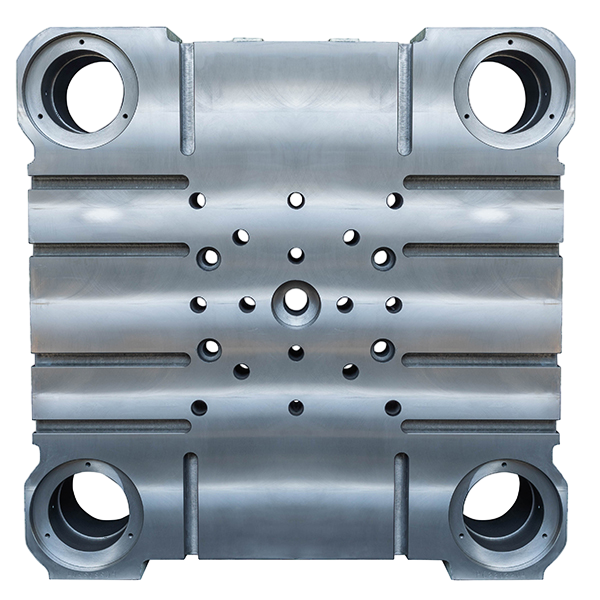

Другой фактор, который делает высоконапорное литье под давлением выгодным, — это его способность производить широкий ассортимент форм и размеров. Формы в этой технологии также очень прочные и долговечные. Они могут изготовить десятки тысяч деталей до необходимости замены, что очень экономически эффективно для производителей. Благодаря этой гибкости высоконапорное литье под давлением получило распространение во многих отраслях, таких как автомобильная, авиакосмическая и оборонная промышленность, где создаются продукты — от маленьких деталей до полных систем.

Металлические изделия часто подвергаются большим нагрузкам и давлению во время обработки. Детали высокоточной литья под давлением специально разработаны для того, чтобы быть очень прочными и выдерживать давление в течение гораздо более длительного времени без разрушения. Эта характеристика является ключевой для компонентов, используемых в автомобилях, мотоциклах и других продуктах, где требуется надежность и безопасность. Слабая или прочная деталь может стать разницей между корректной работой и потенциально катастрофическим отказом.

Изготовление металлических деталей требует тщательного внимания к деталям. Шаг 1: Литые детали высокоточного литья под давлением должны пройти различные проверки качества, включая проверку размеров и формы. Это гарантирует, что все соответствует результату производства. Кроме того, для изготовления этих деталей необходим качественный металл, чтобы они не изнашивались и не разрушались со временем. Производители уделяют особое внимание контролю качества, чтобы каждая деталь была максимально качественной.

Компания Pingcheng сегодня производит компоненты методом литья под давлением высокого давления и располагает командой из 50 технических специалистов с многолетним опытом работы. Их цель — обеспечение высокого качества продукции. Затем изделия проверяются измерительными приборами компании Mitutoyo и координатно-измерительными машинами (КИМ), которые регулярно проходят калибровку. Двукратная проверка гарантирует высокую точность и стабильность качества продукции. Обработка и сборка всех важных деталей находятся под контролем и подлежат полной прослеживаемости.

Цепочка поставок и услуги Pingcheng разработаны для помощи клиентам в достижении их бизнес-целей. Мы специализируемся на расширении и компонентах высокотемпературной штамповки под давлением. PingCheng — это надежный производитель, которого вы ищете. Мы являемся партнером, который предоставляет варианты.

Pingcheng — это полный комплекс услуг по производству компонентов методом литья под давлением высокого давления. Доставка наших изделий — лишь начало нашего партнёрства. Наша служба поддержки клиентов направлена на обеспечение вашего полного удовлетворения. Более 20 лет мы оказываем услуги в области производства и выстроили тесное сотрудничество с известными японскими компаниями. Принцип честного ценообразования Pingcheng основан на многолетнем опыте работы в отрасли и глубоком понимании её особенностей. После получения запроса на расчёт стоимости мы анализируем чертёж в специализированном программном обеспечении и предлагаем оптимальное решение по доступной цене.

Компоненты Pingcheng, изготавливаемые методом литья под давлением высокого давления, основаны на многолетнем отраслевом опыте и глубоком понимании рынка. Мы проверяем чертёж, создаём его цифровую модель в специализированном ПО и затем предлагаем наиболее конкурентоспособную цену.