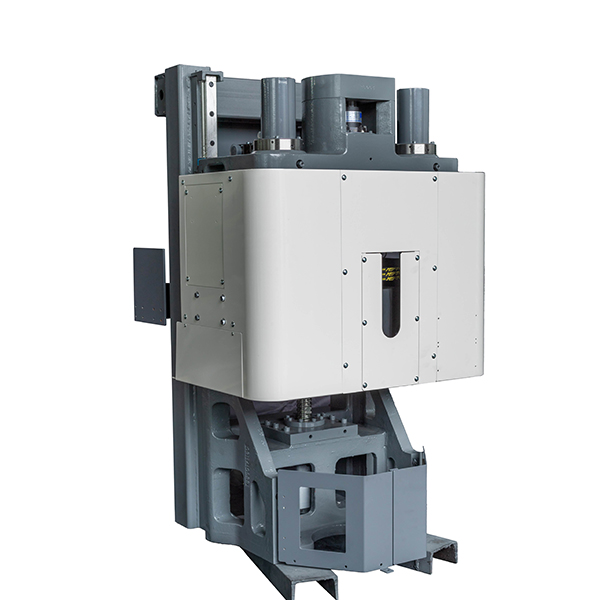

Injection molding: It has been also found, that the injection molding is one of the most important tools for the production of the resin items as soon as and easy for the plastic product. In factories it is used to in the formation of the small plastic products such as toys and large containers. The injection unit is primary mechanism of an IM machine. The Pingcheng injection molding machine involves heating of the plastic and thereafter injecting it in a mold that forms the required shapes of parts. The functioning of the machine itself is almost impossible in case if this particular part is missing. The most critical component as we discuss injection molding machine is injection unit which makes definite that plastic melts suitably plus personnel gets formed in the requisite manner for the final product.

Injection molding process has some stages: one of them is injection unit. The injection unit has to function efficiently or else everything around it will not go well, and this entails that the quality of the parts that you are manufacturing, may not be the best. What one should have in mind when utilizing the injection unit to function properly and make good prints?

One thing which you ought to consider here is the heat. The last requirement to be met is temperature: the material has to be adequately hot for it to melt adequately in the injection unit. Further, the temperature of the plastic must be high enough in order that it would properly flow into the mold. Stress is also one of them. Another condition that exerts major influence is pressure. It has to be forced or pressed with enough force that the plastic occupies the mold from one end to the other. If the pressure is not enough, means can be insufficient to fill some parts of mold completely with the result being unsatisfactory. Proper usage of the injection unit makes it possible to get the best and quality and identical products all the time.

Products of high grade have to be injected formed with great deal of care. Throughout the entire process, care must be taken to meticulously check for things like: Pingcheng vertical injection machine is the unit that guarantees that products produced here are of equal size, shape and quality. Consistency is critical, and this is mainly true for manufacturing companies attempting to meet the needs of the customers.

According to the specific types of plastic used, there may be some things which must be transparent, other must be bendable and still others must be strong as maybe determined by the manufacturers. The injection unit gradually dominates heat, pressure and the way material is fed into the mold. If these factors are controlled properly then the end products will indeed be as required and will enable the intended use as required.

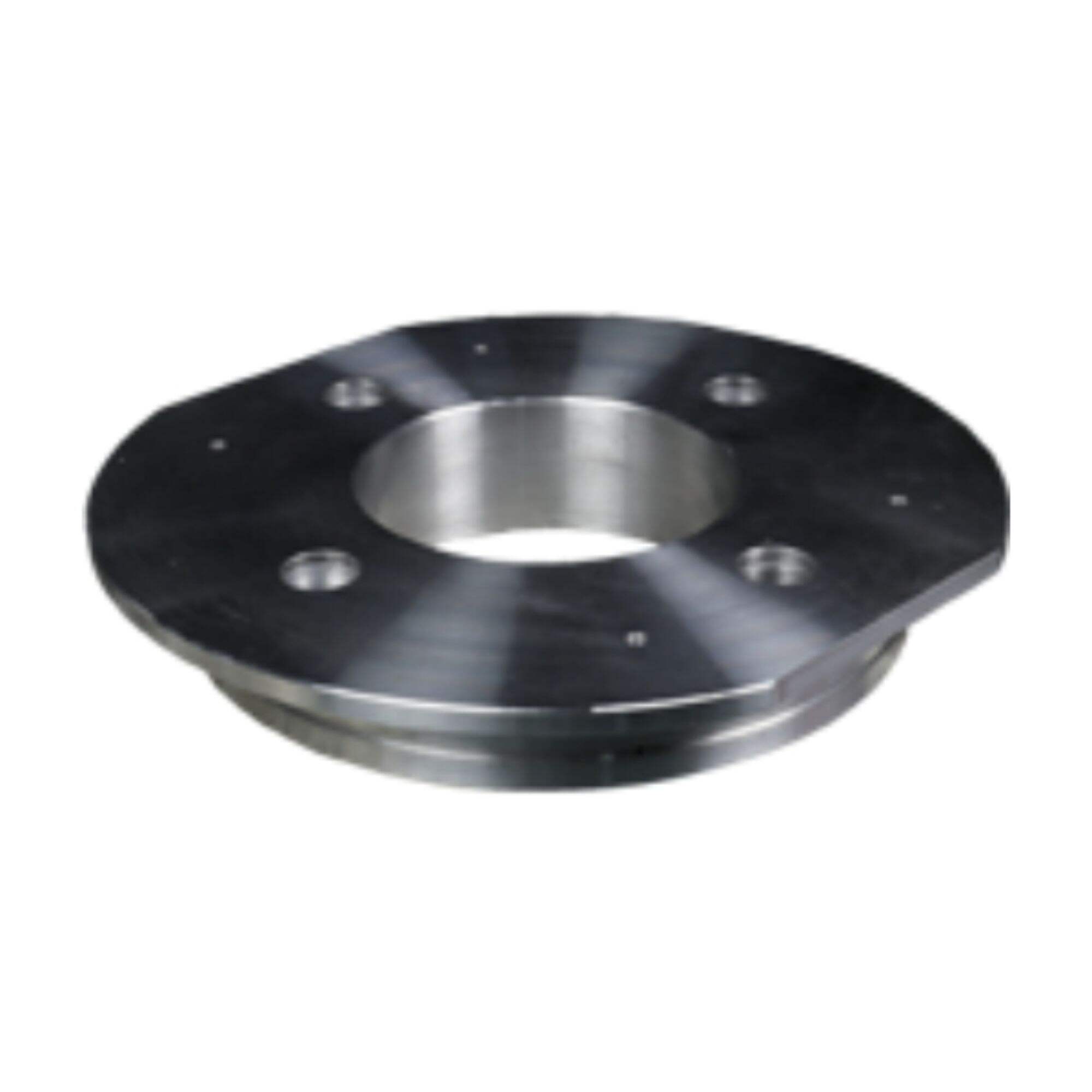

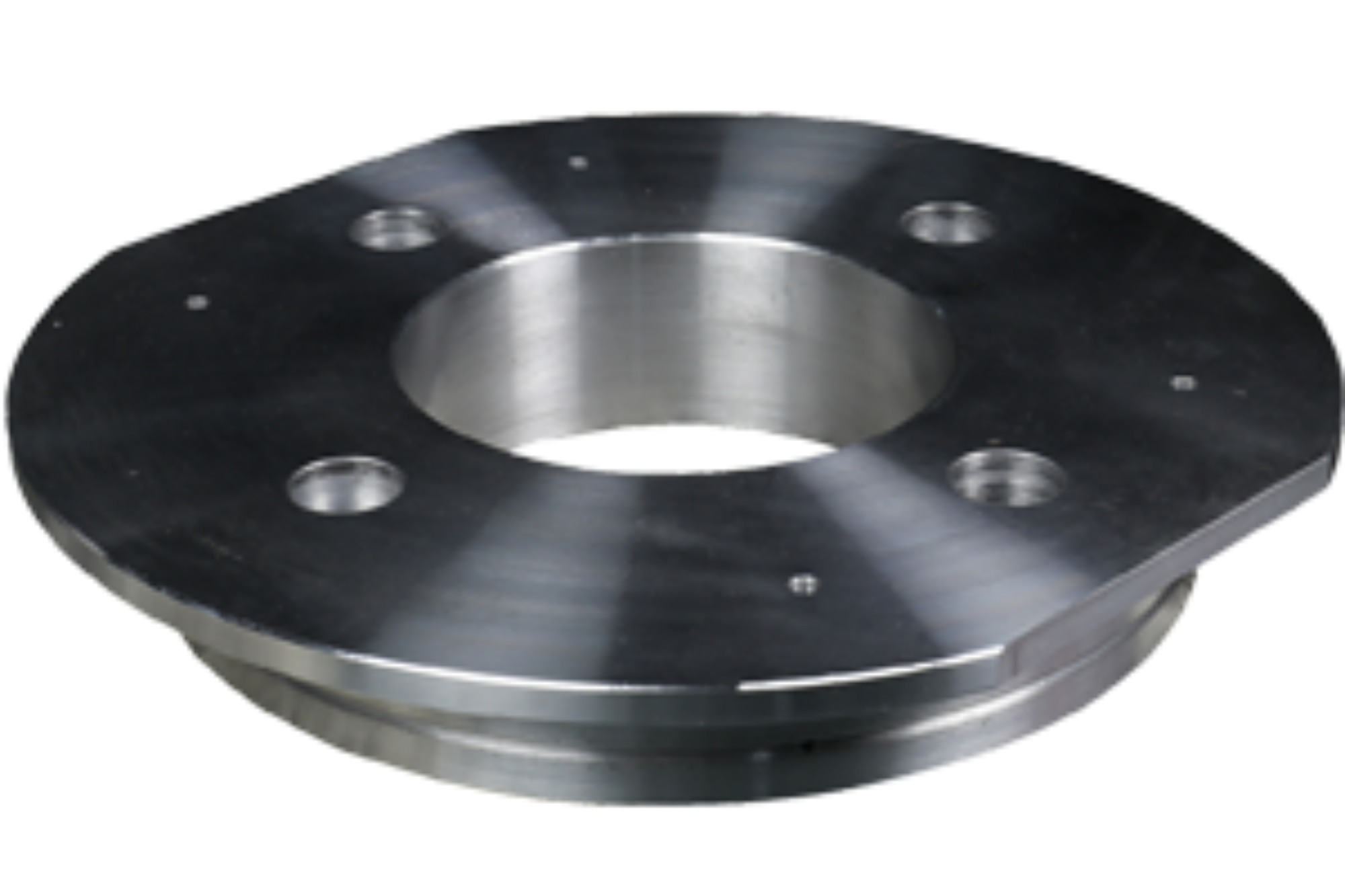

They are the main component of injection molding machine whose function is to inject the melt polymer through a sprue gate into the mold cavity. It needs to be very strong and it will remain as such for a long time to ensure that the machine does its work commendably. This is because an excellent injection unit is one that will be more heat and pressure resistant quickly without degrading or wearing out. And this is where durability plays its most crucial role: to ensure that the rate at which a factory or production line is delivering its products is consistent, and the quality of these products as well.

A well working injection molding machine with a powerful shot unit will go a long way in the successful of products, increasing production capacity and hence improve on the quality of the produced products. The last factor that should be taken in to consideration is the way by which the injection unit can be taken care of. In any case it is possible to ensure long operation of your Pingcheng vertical injection molding machine without any problems if you perform maintenance and check-ups on time.

Pingcheng has now more than 20 manufacturing machines and Injection molding machine injection unit with years of experience. They aim at providing high quality. They then inspect the products by Mitsutoyo measuring tools and CMM that are calibrated on a periodic basis. Double-checking ensures that the product's quality precise and steady. Every key component is traceable and controlled during the machining process and assembly.

Pingcheng's Injection molding machine injection unit and services are designed to helps customers meet their goals for business. We are focused on expanding and increasing the potential and lifespans of your productions. PingCheng is a dependable producers you are looking for. We are a suppliers that provides opportunities.

Pingcheng's Injection molding machine injection unit is based on decades of industry experience and understanding. We review the drawing, model it using specialized software and then provide the most competitive price.

Our customers service focuses your satisfaction. We've been providing machining services and Injection molding machine injection unit with industry-renowned Japanese companies for more 20 years. Based on years of experiences and knowledge of the industry, Pingcheng is dedicated to offering our customers an honest price. We evaluates the drawings using special software and present the best solutions at the most reasonable costs once we have received requests for quotations.