Wind turbines are great sources of green energy. They are the way to make electricity without further damaging our environment or polluting it. A specific type of wind turbine is the high gear box wind turbines. This turbine works little differently than the previous one due to this having a gear box used for stepping down and then finally transmitting power produced from wind energy.

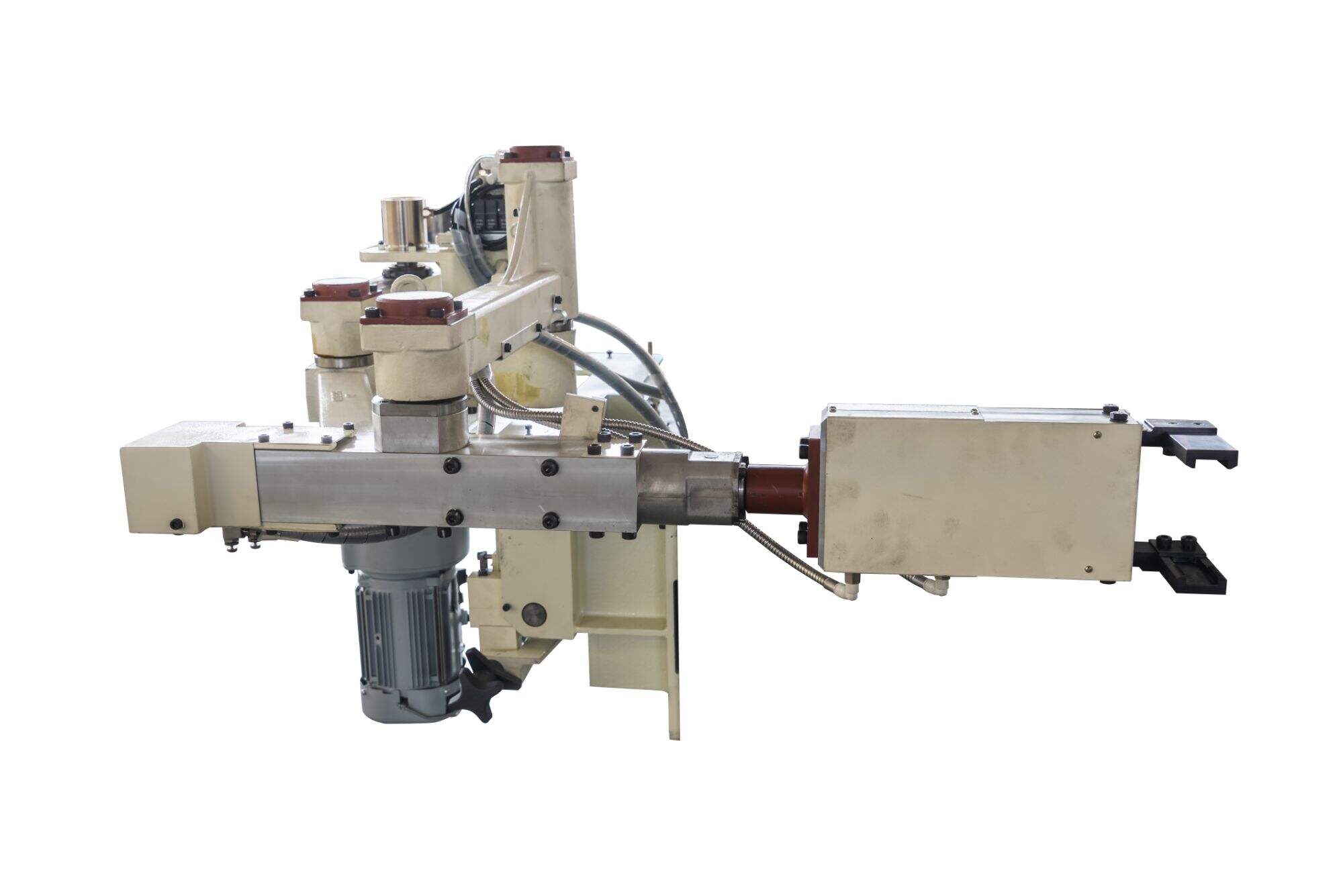

Interesting Things About Gear Box Wind Turbine On the turbine, wind catches blades first. The wind when blows, makes the blades move performing a circular motion. It spins a part called the rotor. The rotor is coupled to a gearbox -- essentially, it's the same thing that gives an electric motor its "flop-torque" at extremely low rpm conditions. The gearbox takes this rapid rotation and passes it to the generator, which spins at the speed required for efficient generation. Generator — This is possibly the most crucial component of all because it converts a spinning motion into electricity. From here, the electricity is distributed to homes and businesses. We power a lot of things on it — lights, computers and other appliances.

In recent years there have been many improvements made in gear box wind turbines. But they have scaled these turbines up in size and strength, enabling them to capture more wind which enables the production of even more energy. Moreover, materials for the boxes themselves were upgraded. The bulletproofing makes the gear boxes tougher, allowing them to weather tough conditions such as high winds or heavy rain. So in other words gear box wind turbines will perform better and have a longer shelf life, which is good for green power.

The wind turbines needs to be serviced so that the gear box there-in will not damage. That is why maintaining them well increases their lifeline and helps them work in an optimum manner. Care of the equipment includes routine checking and cleaning up from the gear-box to make sure it is not dirty or damaged. It is also key to replace any worn parts, that way your turbine works at peak performance. This is where mechanical oil aids in lubricating the moving parts to reduce friction and wear. The gearbox is an important part — should it go wrong, it must be fixed or a replacement fitted without delay. This easy step can help avoid larger issues farther down the road.

The wind turbines are made in two types: gear box and direct drive. The main difference between the two types of wind turbines is that direct drive wind turbine has no gearbox. Its rotor is simply directly connected to the output shaft with a generator on top. This means they have fewer components that can wear out. Currently, the gearbox wind turbine is one of the least expensive to produce, so it is often seen. These are also easier to maintain as the tech is well known. Yet direct drive turbines are typically more compact and with less moving parts than gear box units, meaning they should be well maintained to provide reliable electric power equipment for years.

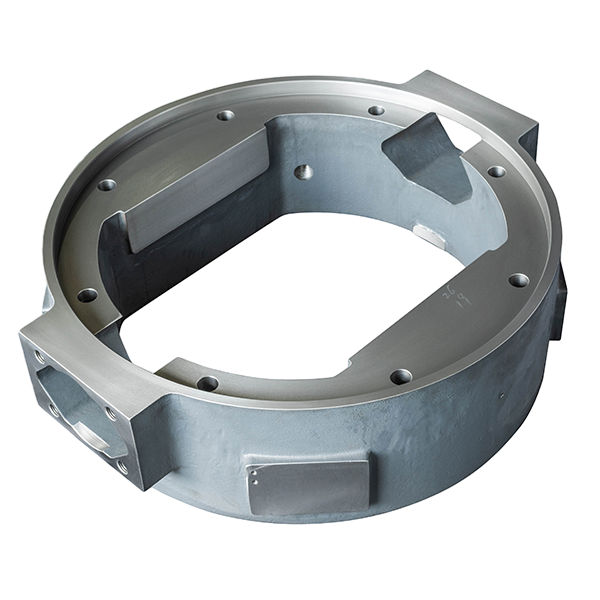

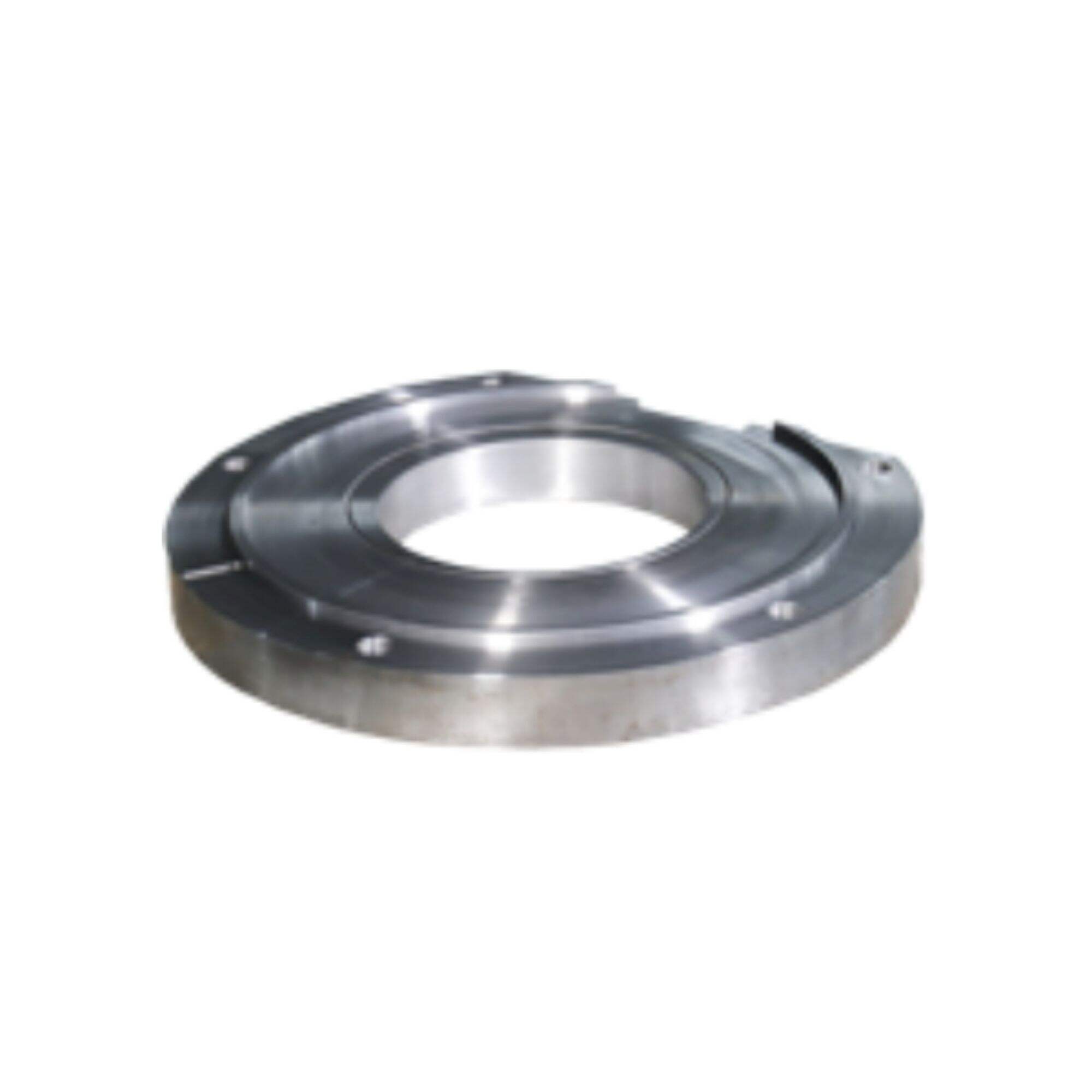

Pingcheng is now home to more than 20 manufacturing machines and more than 50 skilled technical staff. They gear box wind turbine. Then the products are inspected by Mitsutoyo measuring tools and CMM that are periodically calibrated. Double-checking ensures that the quality of our products precise and stable. Every single component can be traced and monitored during machining and assembly.

Pingcheng's commitment for honest pricing is founded on years of experience in the industry and knowledge. After we receive the request for quote, we review the drawings and simulate gear box wind turbine as soon as we can, and provide the best solution for your cost.

Pingcheng is dedicated to helping customers gear box wind turbine by providing our supply chains and services solutions. We strives to help you extends and maximize the life and worth of your products. PingCheng is the reliable manufacturers you're looking for. We are a company that delivers potential.

Pingcheng a total process and lifecycle partners. The shipping of products is just beginning of our partnerships. Our customer service is all about ensuring your satisfactions. Since over 20 years we've provided machine-tooling services and established a strong partnerships with renowned Japanese firms. Our commitments to honesty in pricing is based upon our years experiences in the industry and our gear box wind turbine. We review drawing using special software and presents the best solutions at the most reasonable costs once we have received the request for quotations.