A mold clamp is a key tool that helps in doing many jobs and the places requirement. It is designed to help the mold cling together so that materials can be properly formed and molded. Clamps are necessary for all the molds that produce any products from automobile parts, to medical equipment. Today, more advanced looking style of mold clamps are out in the market which help you work better and faster with great efficiency. The clamps that are now being used by professionals actually come with modern designs, and they can therefore save a lot of time while increasing the quality of the products overall.

Proper mold clamping is crucial for efficiency and productivity. Having the molds held firmly in place ultimately saves time during manufacturing and ensures that every item comes out perfect. Getting your molds fixtured in place tight with the right mold clamp helps you to achieve repeatability and consistent results. This means employees can have confidence that the items are manufactured to a consistent standard, every time they are made.

The strength of the mold clamp is tailored made to hold up well and always produce a high quality manufacturing process. They are constructed of great quality materials and can last for long periods even after being used frequently. These clamps are able to keep even the most difficult and intricate of molds in place regardless of what you throw at them.

These strong mold clamps are very sought after and used in virtually all working industries. They are used for car manufacturing, medical device production and fashion designs to name a few. Having the molds right where they need to be when things are formed in these kinds of applications is critical. This ensures that the avoidant manner and alignments can be detected, preventing some further issues in future.

Mold industries like aerospace, electronics and construction often utilize a mold clamps to secure their molds in place during the manufacturing process. Doing this without using these clamps can make mistakes more probable which will result in delays. These delays are expensive and create safety hazards for the workers. This is why it is necessary to have the correct mold clamps in order to keep a safe and effective environment at work.

Another example of a recent mold clamp design is known as the hydraulic mold clamper. By applying hydraulic pressure, it keeps the mold in place with minimum possible hassle to operate but at larger repeatability and accuracy. An alternative would be to use a magnetic mold clamp. The rotary mag clamps (I may have put indent instead of clamp and vice versa in my discussions) simply use magnetic force to hold the mold securely, making it easy without being too complex thus ensuring more consistent results each time.

To sum up, mold clamps are a critical tool in every job involving molds! They serve as a means to retain molds during the manufacturing process, playing a role in directly translating everything to production accurately and consistently. Together, this means less downtime and. as a result eliminating part defects caused by the delay in process!

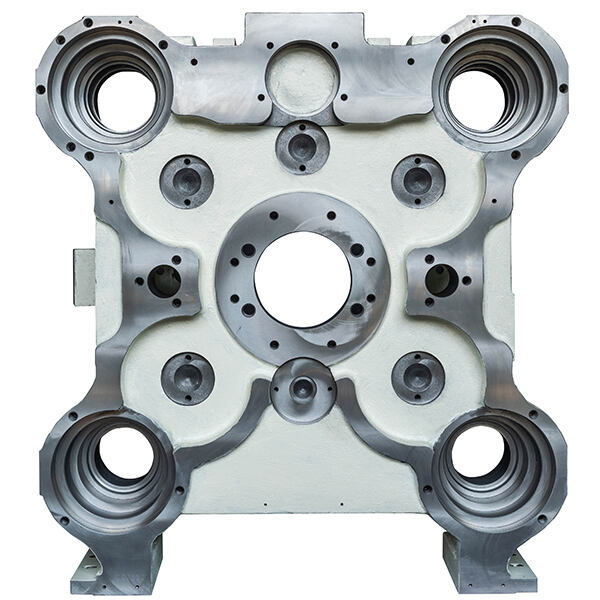

Pingcheng's mold clamp is founded on decades of industry experience and a deep understanding. After we receive quotation requests, we examine the drawing and simulate in specialized software right away, and then provide the most effective solution with a fair price.

Pingcheng is now home to more than 20 manufacturing facilities and 50 experienced technical workers. They mold clamp. Then, the product is inspected by Mitsutoyo measuring instruments and CMM that are periodically calibrated. Double-checking makes sure that the quality of our products precise and steady. The machining and assembly of all the key components are controlled and traceable.

The supply chain and services of Pingcheng are designed to aids clients achieve their goals in business. We mold clamp as well as maximizing the values and life of your manufacturing. PingCheng is a dependable manufacturer you are looking for. We are a suppliers that offers a variety of options.

Our customer services focused on your satisfaction. For over a decade we've provided machining services and mold clamp with well-known Japanese companies. Pingcheng's adherence truthful pricing is based upon our years of industry experience and knowledge of sector. We analyze the drawing special software and offer the best solutions for an affordable price once we have received an inquiry for quotes.