As you look at plastic toys, water bottles and phone cases that surround us in our everyday life ever though of thinking how they are made. An interesting technique employed to produce these everyday items is the injection mold machining. This novel technique is characterised by the possibility of a specific machine tool that heats certain plastic and then produces quickly, with ease vacuum form moulding according to random forms (in this way making cuts)

Injection mold machining is known for its high precision capability to have complex shape and contour items done. In addition, it is fast and one can make countless items in a short period. For what it's worth, some can manufacture millions of parts in a mere few days - an aspect that illustrates how prevalent this method is throughout the manufacturing industry.

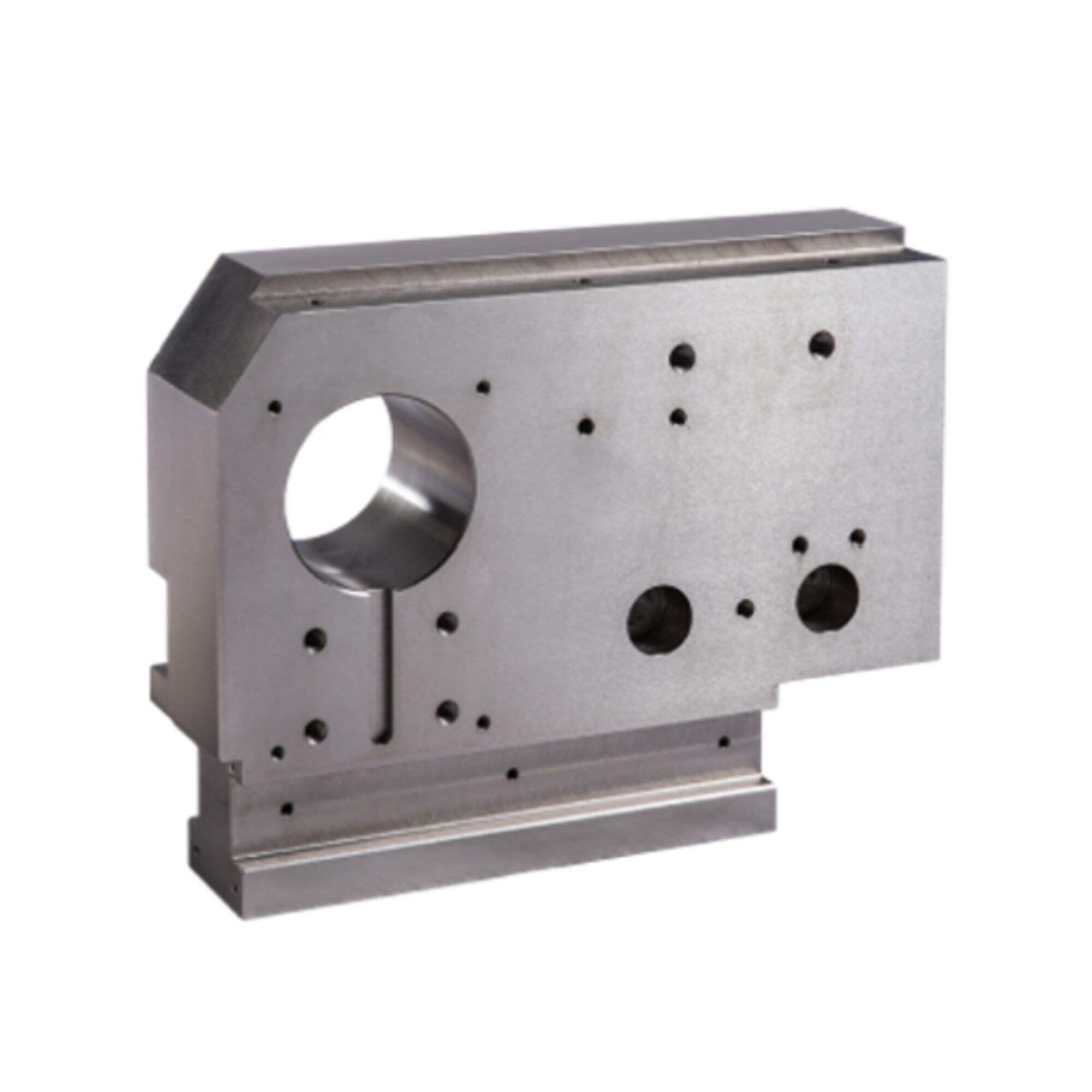

Injection mold machines are high-tech tooling machinery. They are state-of-the-art devices that come with unique computer programs which control every process in the production of parts. This automation level requires that the proper amount of machinery manufacturing can be accomplished quickly and precisely, which in turn should save companies a lot of time and money. In addition, their machines are efficient and capable of outputting items at a high level of quality on an ongoing basis.

There are some other important factors to be kept in mind when one is already getting into the industry of injection mold machining. It is essential for the plastic to be kept at a certain temperature, otherwise it may interfere with the manufacturing process. As a further precaution, it is important to ensure the machine used runs at maximum efficiency - moving too slowly will result in long production times and going far above optimum capacity can warp the plastic while being shaped.

Injection mold machining has revolutionized many aspects of the manufacturing industry. With faster and more efficient production speeds than ever before, this has enabled businesses with volume manufacturing capabilities such as never before seen which reduces costs that in turn leads to the prices being lowered for the consumer whilst also increasing profits. This machine precision guarantees crafting items of top class quality and creates an improvement in the customer satisfaction.

At the end of each, injection milling is a typical process for most businesses at once as it provides speed and rapid production. If you would like to get more information about this interesting subject, or if you have questions in general related with manufacturing industry, head over online and do some research; it may prove helpful. Who knows, it may even inspire you to be creative and create your very own inventions!

Pingcheng is a injection mold machining and lifecycle partners. The shipping of our products is only the beginning of our partnerships. Our customer services is about ensuring your satisfaction. Since more than 20 years ago, we have offered manufacturing services and have built a closed collaboration with well-known Japanese firms. Pingcheng's dedications to fair pricing is based upon our years of experiences and understanding of this sector. We analyze the drawing in an advanced software program and then provides the most efficient solution at the most reasonable cost once we have received the requests for quotation.

Pingcheng is dedicated to helping customers injection mold machining by providing our supply chains and services solutions. We strives to help you extends and maximize the life and worth of your products. PingCheng is the reliable manufacturers you're looking for. We are a company that delivers potential.

Based on decades of experience and injection mold machining, Pingcheng is dedicated to providing its customers with a fair price. We examine the drawing, model it with specialized software and then give you the most affordable price.

Pingcheng has at injection mold machining and 50 technical employees who have experiences. They are committed providing tops quality. Mitsutoyo's measuring instruments and CMM are calibrated regularly. The double-checking keeps quality reliable and accurate. Each keys part traceable and controlled during machining and assembly.