Pressure units for injection are a type of special machinery that is just one of those used to create numerous different products. These machines are very useful in industries. These are then mixed together and melted down from small pieces of plastic that are called pellets. Once the plastic is melted, it can be molded into a cornucopia of shapes and sizes. Injection molding is everywhere around us — from toys, packaging containers and even car parts!

The way an injection pressure unit operates is rather peculiar. The plastic pellets are loaded in a part of the machine called hopper. The pellets are mixed and heated in the hopper before they go soft and melt. There is a large screw in the machine that pushes pellets into an enclosed heated area where they turn to liquid. This melted plastic is super hot. The molten plastic is then forced at high pressure into the mold. Then The mold is cooled down, same time plastic cools off and solidifies in the desired shape. This all occurs in a manner of seconds so companies can churn out many goods quite fast.

Those vulnerable ones can get whacked repeatedly using injection pressure units to help make the whole process speedier and more convenient. The machines are built to produce parts rapidly, which is perfect for mass producing items. This is particularly useful for factories that have to produce large volumes of products. Since the machines are doing much of the work, companies need to employee fewer workers; this could represent significant savings in labor.

The fact that these machines save you money, is also good for the environment. They require less plastic, electricity and heat than other manufacturing methods. Therefore this method lowers waste and reduces the amount of resources needed to produce goods. Injection pressure units have specific intelligent automatic controls for manufacturing, which greatly reduces the probability of human error. This automation results in products being more uniform and of higher quality.

The best part about injection pressure units are their capacity to make products that look and feel like they should. Using precise controls, these devices can control how much pressure, speed and liquid used in the event that filling a mould. This results in every good produced is like another one. That is crucial, especially for the production of components such as car parts that require compliance with high safety and quality standards.

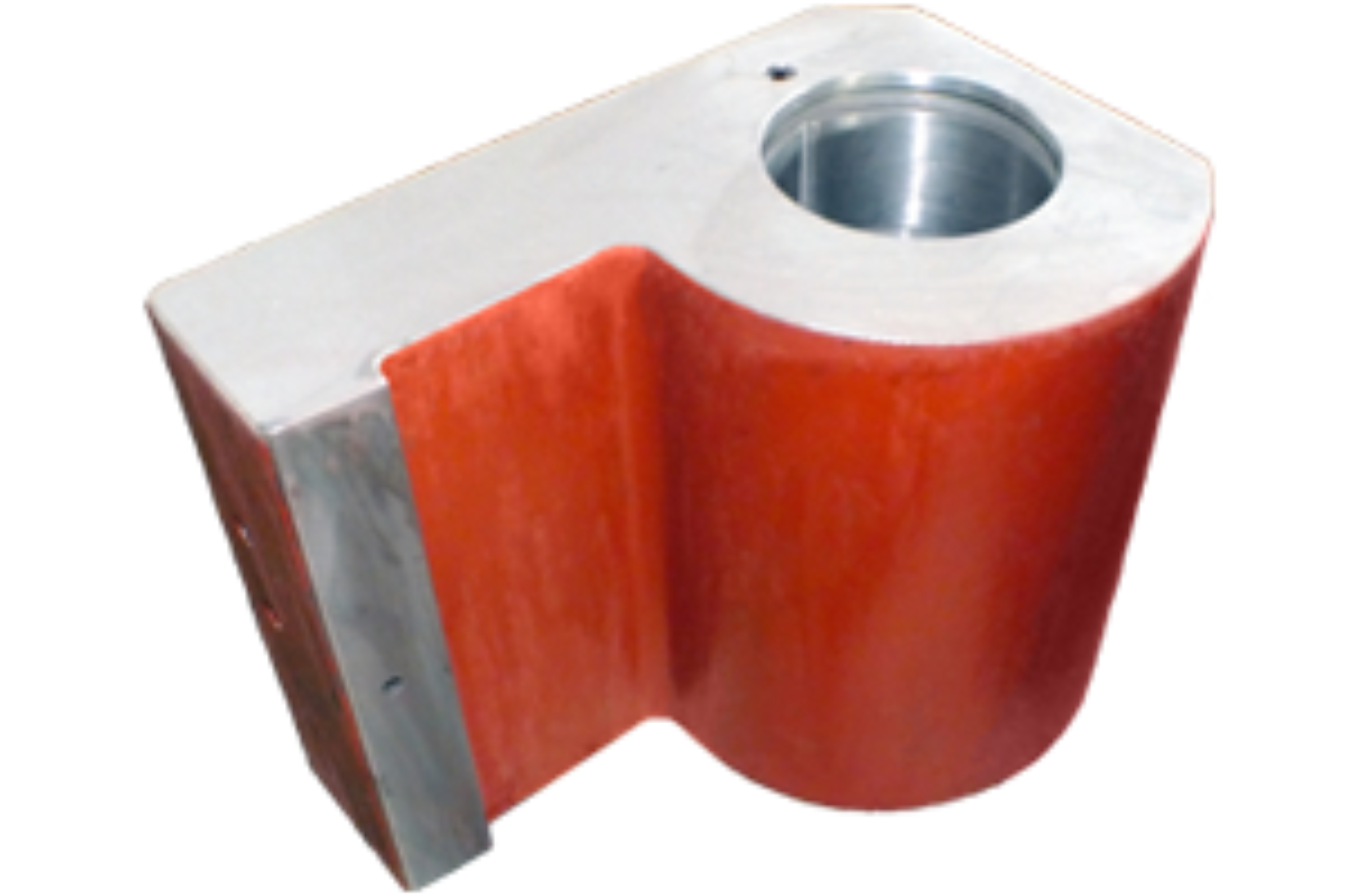

If you want to make small parts, for example, a soft plastic toy wheel. You might not need that large injection pressure unit However, if you are interested in making bigger objects then at some point you will need a larger machine that can carry more than top maximum weight. For example, some units are better suited for rubber or a certain kind of plastic. You will need to select a machine that is capable of working successfully with the materials you have decided on.

When an injection pressure unit is being put to good use, this allows for manufacturers to get the most out of their yield. It basically is the amount of items made to the raw material used, that ratio or percentage. Utilizing the proper pressure injection unit and having an accurate command over the method enables manufacturers to produce much more of their products as well as throwing away far less components.

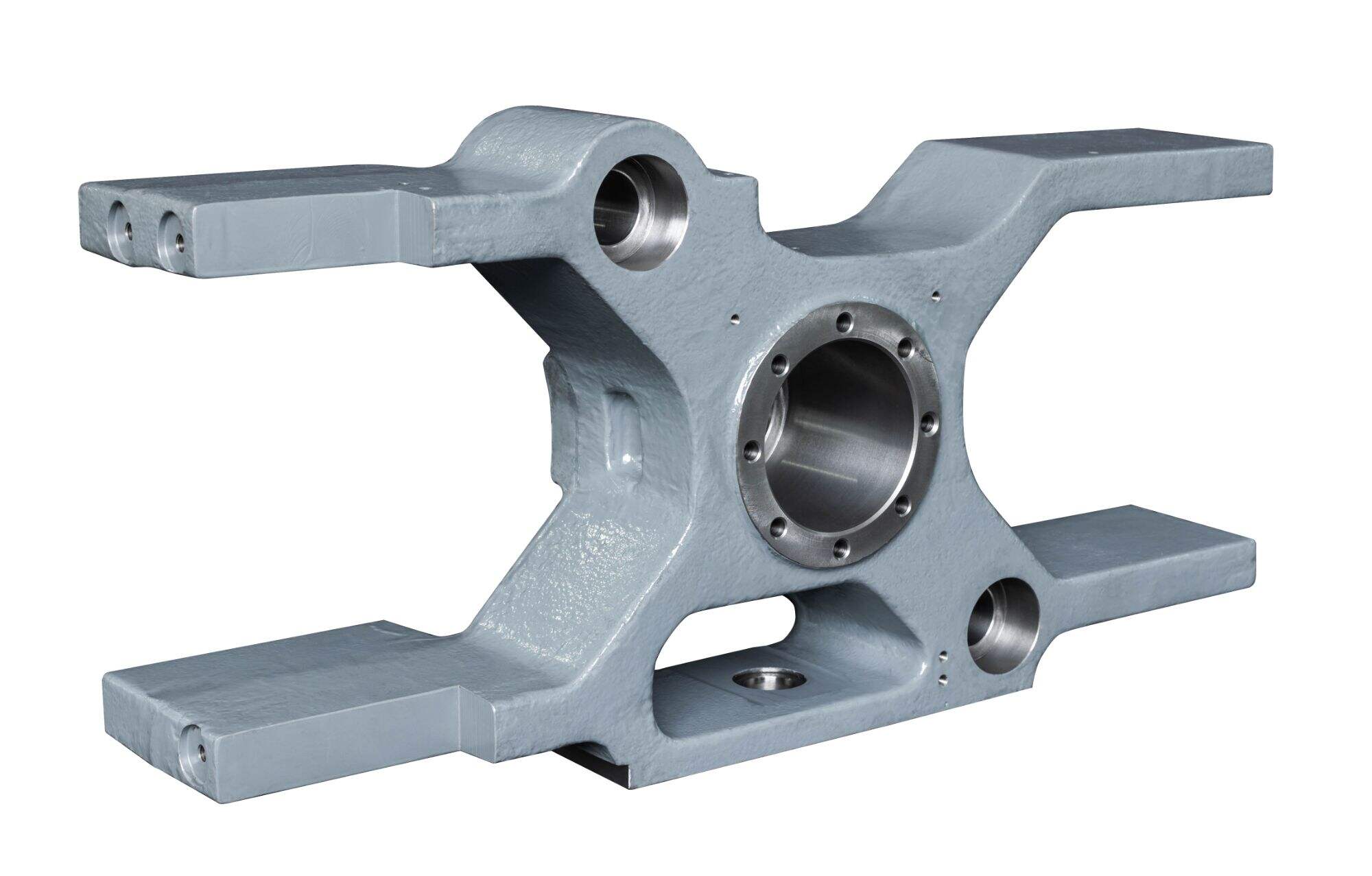

The supply chain and services of Pingcheng are designed to aids clients achieve their goals in business. We injection pressure unit as well as maximizing the values and life of your manufacturing. PingCheng is a dependable manufacturer you are looking for. We are a suppliers that offers a variety of options.

Pingcheng's commitment for honest pricing is founded on years of experience in the industry and knowledge. After we receive the request for quote, we review the drawings and simulate injection pressure unit as soon as we can, and provide the best solution for your cost.

Pingcheng is now home to more than 20 manufacturing machines and more than 50 skilled technical staff. They injection pressure unit. Then the products are inspected by Mitsutoyo measuring tools and CMM that are periodically calibrated. Double-checking ensures that the quality of our products precise and stable. Every single component can be traced and monitored during machining and assembly.

Our customers service focuses your satisfaction. We've been providing machining services and injection pressure unit with industry-renowned Japanese companies for more 20 years. Based on years of experiences and knowledge of the industry, Pingcheng is dedicated to offering our customers an honest price. We evaluates the drawings using special software and present the best solutions at the most reasonable costs once we have received requests for quotations.