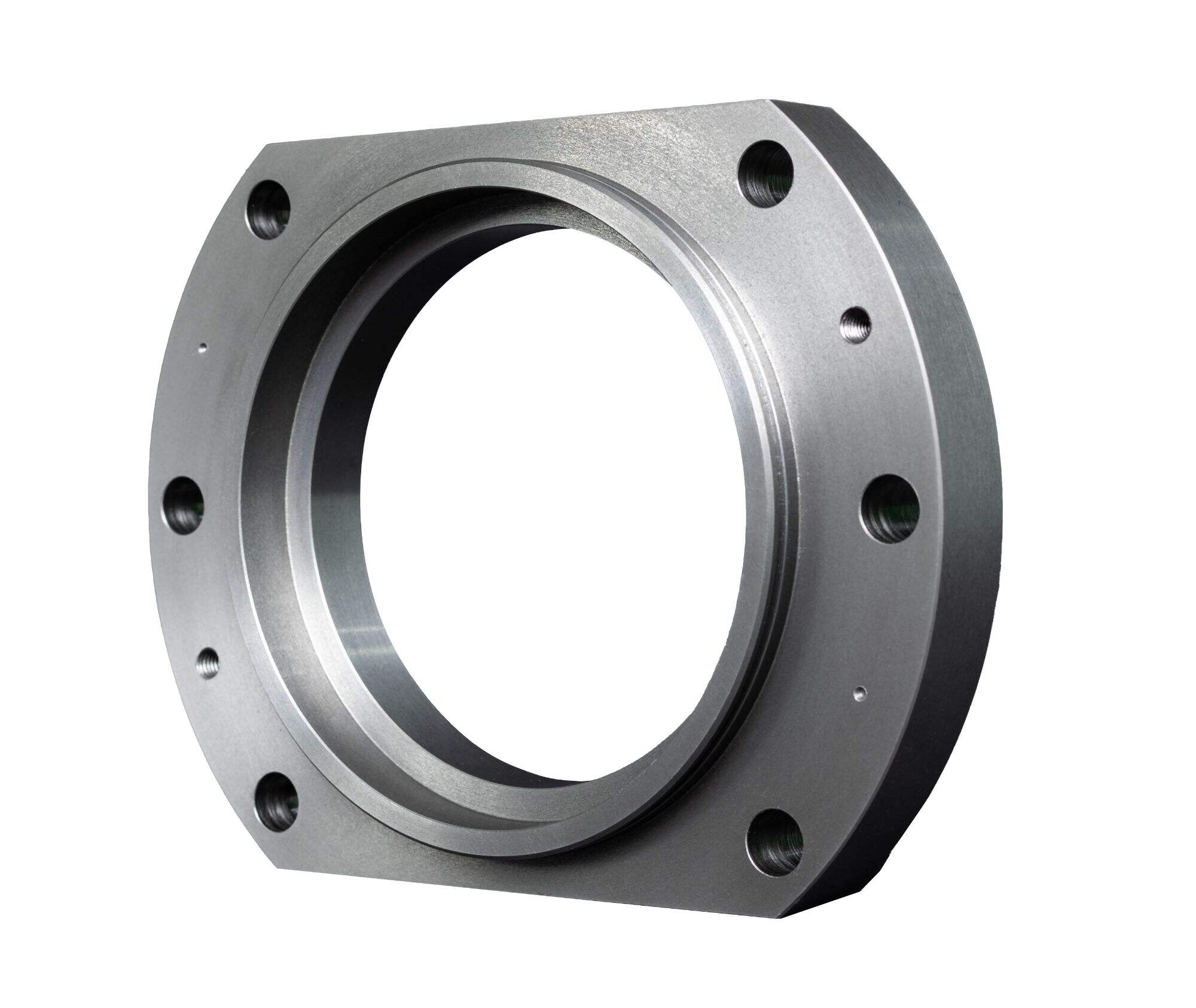

The motor end caps are the crucial part for protecting and performance enhancements of motors. Typically, such caps are made of tough materials (eg., metal and plastic). They are installed on the edge of the motor to keep off dust and small particulate matter from entering into destroying the motor. In this way they motor end caps contribute to make the fixed shape of the motors so that in long run it can work properly. If dirt stopped the motor running in a toy car, which is why Pingcheng motor bearing cover like these are so handy.

Motor capacitors are necessary parts not only for motor itself, but also one of the essential components in almost all machine we use every day. Take washing machines, vacuum cleaners and dishwashers for instance. They function because they make use of motors and the removal of opening end caps would negatively affect their functionalities. If the caps were not present, then as pointed out some other components could get damaged and also I believe that damage to motors would result in failure of machines to operate properly. We could, however run into issues within our homes and offices or even just in everyday use. Only once the end caps are installed, the motors can function properly to give us a hand in our daily chores and help make lives easier.

If you have a machine using motor end caps, so now those that are designed to reduce the volume of screws used. Advantages of Going to Better Motor End Caps Newer caps are built to standard and helps the motor go even faster while using less power. Pingcheng motor end cover can also minimize the noise that a motor produces, so they are perfect for providing you with peace at your home and workplace. In addition, these state-of-the-art caps can also protect the motor from overheating and subsequent damage. You can save cost on repairs and replacements by lessening the overall risk of damage. In other words, this is a convenient way of upgrading your motor end caps to keep them running longer.

As with anything else, motor end caps can fail eventually. And when they do, it can change how well the engine operates. If you notice that your motor has a very difficult time moving or it might seem weaker than usual than the base cap is what could be not working correctly. The gas might not allow it to start as easily, even potentially running harder. More alarm bells are loud noises that you didn't previously hear, strange smells from the motor or shaking and vibrations through in machine. If you do, make sure to check the motor end cap for replacement.

Choosing the correct motor end cap is crucial make sure that you select an appropriate one so that your machine works well for an extended time. Wide hat brims and neck flaps provide the best protection from UV rays so these are important things to look for when trying different caps. The First Thing You Should Consider is the Type and Size of Pingcheng bearing end cap covers. It come in various styles and may vary depending on the motor. Then, think about where the machine will be used. For example, if it will come into contact with moisture (like a wet environment), you may need to find a cap that can handle the dampness. And, lastly, consider the machine's power requirements. Understanding the electric needs might likewise aid you in preferring completion cap suitable for your objective It can be pretty hard to find the perfect motor end cap for your machine, and if you are not sure that much about them then it is always recommended suggesting yourself an expert in order to research more on this topic.

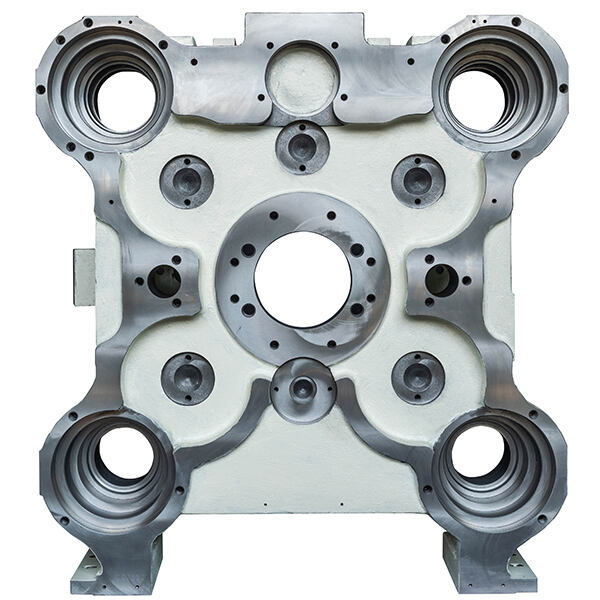

Pingcheng has now more than 20 manufacturing machines and Motor end cap with years of experience. They aim at providing high quality. They then inspect the products by Mitsutoyo measuring tools and CMM that are calibrated on a periodic basis. Double-checking ensures that the product's quality precise and steady. Every key component is traceable and controlled during the machining process and assembly.

Our customer service focuses on your satisfactions. We have been offering an Motor end cap and developing a strong cooperation with industry well-known Japanese enterprises for over 20 years. Based on decades experience and comprehensions of this industry, Pingcheng is dedicated to offering our customers honest prices. We review the drawing using specialized software and provide most effective solutions at the most reasonable cost the moment we receives an inquiry for a quotes.

Pingcheng's Motor end cap is based on decades of industry experience and understanding. We review the drawing, model it using specialized software and then provide the most competitive price.

Pingcheng's Motor end cap and services are designed to helps customers meet their goals for business. We are focused on expanding and increasing the potential and lifespans of your productions. PingCheng is a dependable producers you are looking for. We are a suppliers that provides opportunities.