BusinessHave you ever asked yourself, we are surprised to see some machines move smoothly and fast. Welcome to the intriguing world of linear slide assembly, a technology that has changed the way objects are moved along in a straight line.

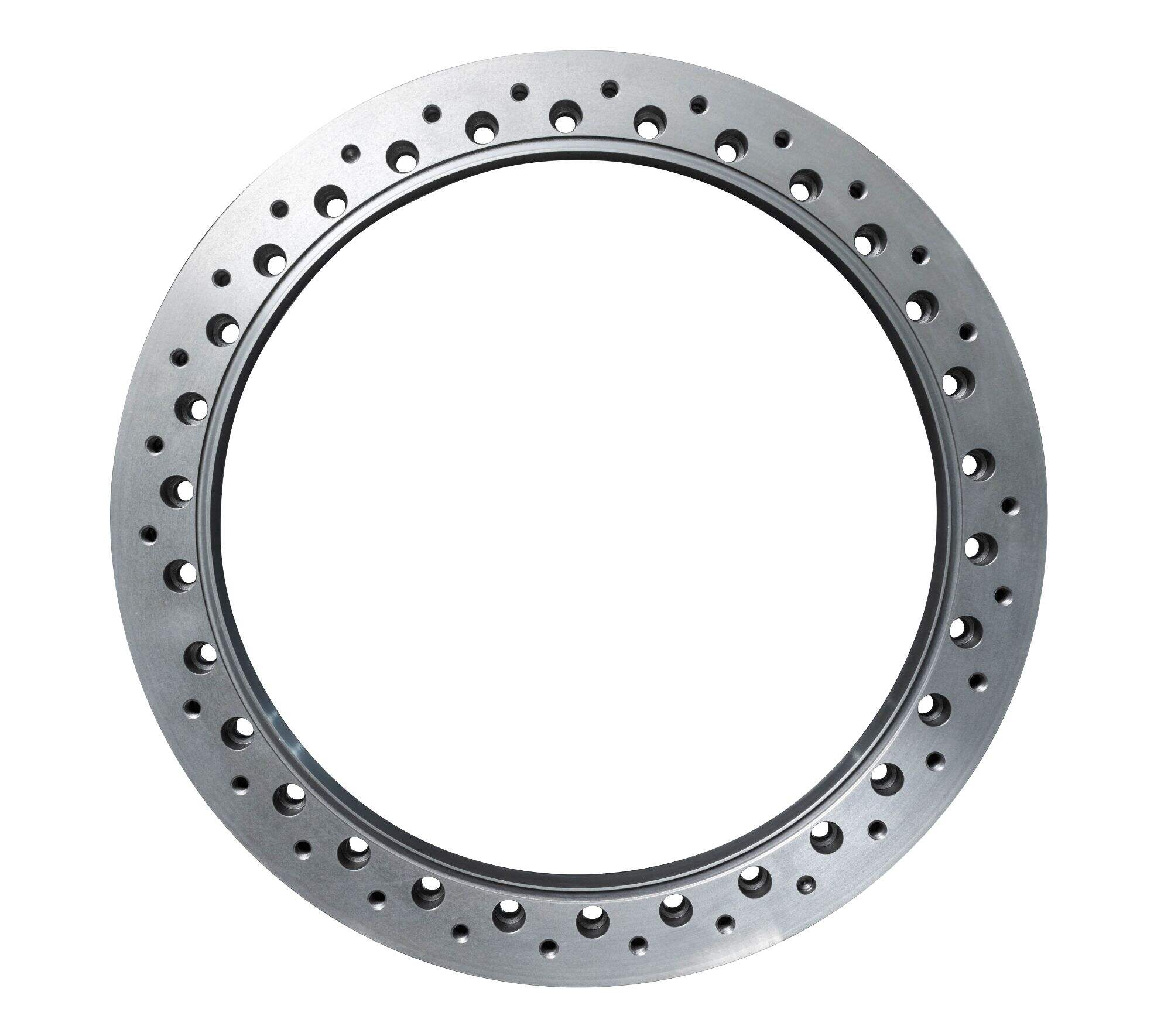

And think of a bunch of bits who collaborated to make sure that an object skates smoothly across the surface in one nice straight line. That is the beauty of a linear slide assembly. These parts used special rollers or bearings to minimize friction for a safe and exact movement. The linear slide assembly method is really the better option.

Introduction Some of the main advantages include added efficiency for machines. Less wear and tear on the machine means an increased life expectancy as well as maximized performance. Furthermore, Linear Slide Assemblies Offer the Benefits of PrecisionWhen it comes to any industry which relies upon machinery for a large part or even all its production process, linear slide assemblies make perfect sense because they are among one of the most precise products available.

The simplest way to understand how a linear slide assebly works is by looking at two basic principles - friction and motion. Friction is a kind of force, opposite to the motion between two objects in contact with each other. As objects touch the other they cause/ undergo friction which leads them to decrease speed and face corrosion.

In contrast to this, is motion that does occur by moving from one position to another. A linear slide assembly uses rollers or bearings to create motion that allows the object to easily glide across a track. This reduces friction: the result is effortless, fine-grained movement and maximized efficiency.

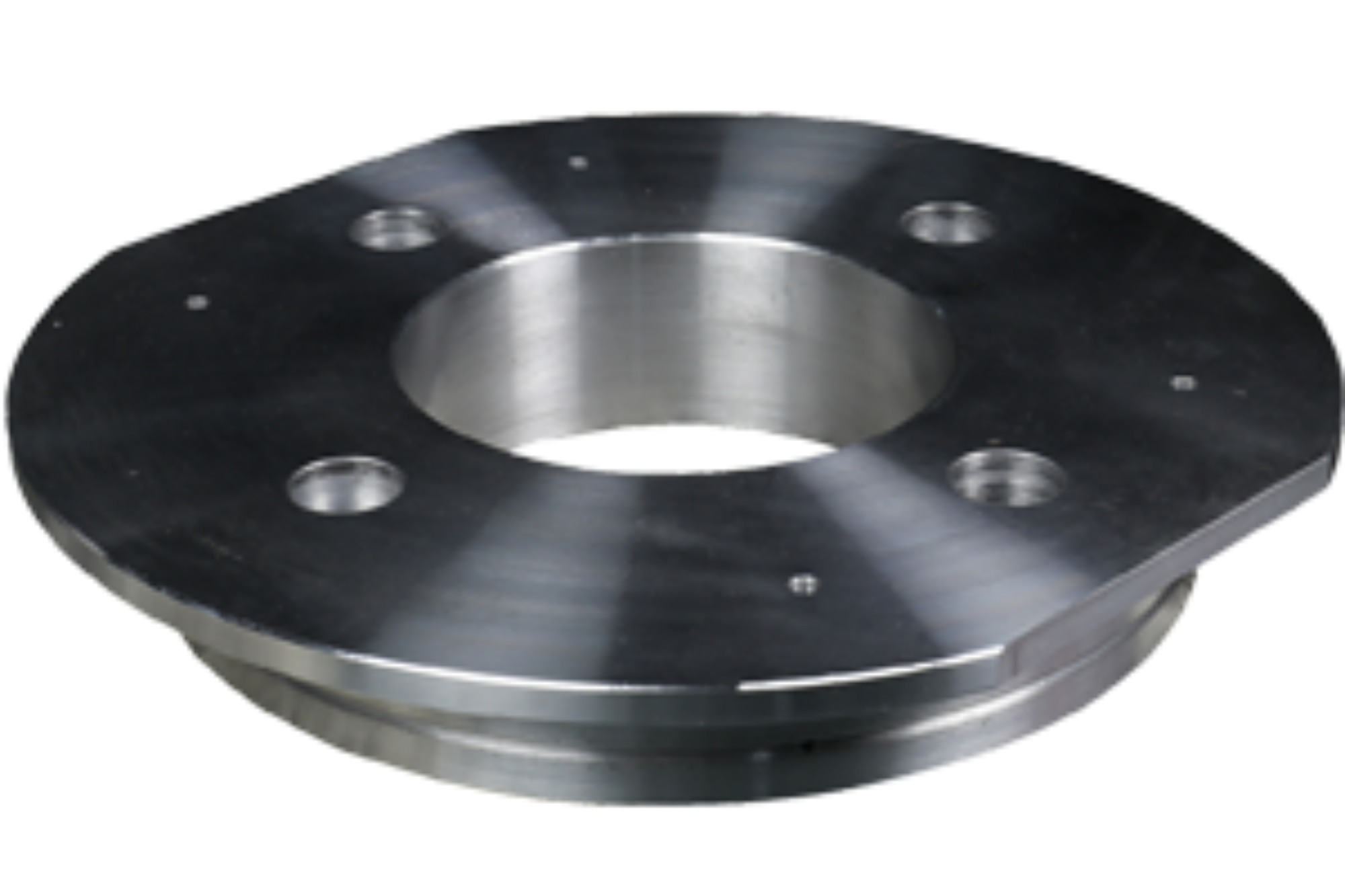

But if all you want to do is build the assembly for your own linear slide, there are a few things you need to keep in mind. The first is the part selection, which includes not only choosing a proper track but also selecting rollers and any other parts needed. Proper fitting and free movement of the assembly by greasing them are also crucial in an assembling process.

Linear slide assemblies are used across a wide range of industries, from manufacturing to robotics and even aerospace. Their applications are absolutely indispensable, anywhere where accurate positioning is mandatory. This could be seen in manufacturing plants, where linear slide assemblies are used to move raw material between various stations.

Linear slide assembly best practices Using quality parts that have been designed to work together, making sure lubing and maintenance is good along with thorough testing should lead the saw running like The Mill.

Improvements in Next-Gen Technology and the Need for Better, More Durable Linear Slide Assembly

Linear slide assemblies may not be the most recent invention, but advances in technology have made it possible to use them better and more widely than ever. Engineers are considering a certain nanoscale linear slide assembly - really as puny and precise an affair you might ever hope to see - that could end up in everything from medicine to electronics. The benefits could go even further install by improving efficiency of linear slide assemblies with still lower friction, allowing for machinery to be more precise and have longer lasting performance.

Linear slide assembly is therefore an interesting and important area of the engineering discipline to explore. Understanding the Advantages and Principles: Not only are we able to create faster, more reliable machines using linear slide assemblies; By capitalizing on benefits as well as sound fundamentals of nature... We help move the industry forward, and we hope you do to by keeping up with all of these cool new things that are coming out!

Pingcheng is committed to helping our customers reach their goals in business through our own supply chain and services solutions. We are focused on helping to extend and linear slide assembly of your products. PingCheng is a dependable manufacturer that you're searching for. We are a trustworthy supplier of opportunities.

Pingcheng has at linear slide assembly and 50 technical employees who have experiences. They are committed providing tops quality. Mitsutoyo's measuring instruments and CMM are calibrated regularly. The double-checking keeps quality reliable and accurate. Each keys part traceable and controlled during machining and assembly.

Pingcheng is a linear slide assembly and lifecycle partners. The supply of the products is just the beginning of our partnerships. Our customer service is about ensuring your satisfactions. We have been offering the machining services and establishing a close partnerships with well-known industry Japanese companies for more than 20 years. Based on decades of experiences and knowledge of this field, Pingcheng is dedicated to offering our customers an honest prices. We examine the drawing with an advanced software program and then provide the best solution at a reasonable prices once we have received the requests for quotation.

Pingcheng's linear slide assembly is founded on decades of industry experience and a deep understanding. After we receive quotation requests, we examine the drawing and simulate in specialized software right away, and then provide the most effective solution with a fair price.