Heat press platens are instruments that are used to an extraordinary degree, especially in the realm of clothes-making. These are flat metallic surfaces that can be heated and then designs can be transferred from one fabric onto another using these platens. Read on to discover more about what heat press platens are, and why they could be useful for you. You will understand how they function and why these are really good.

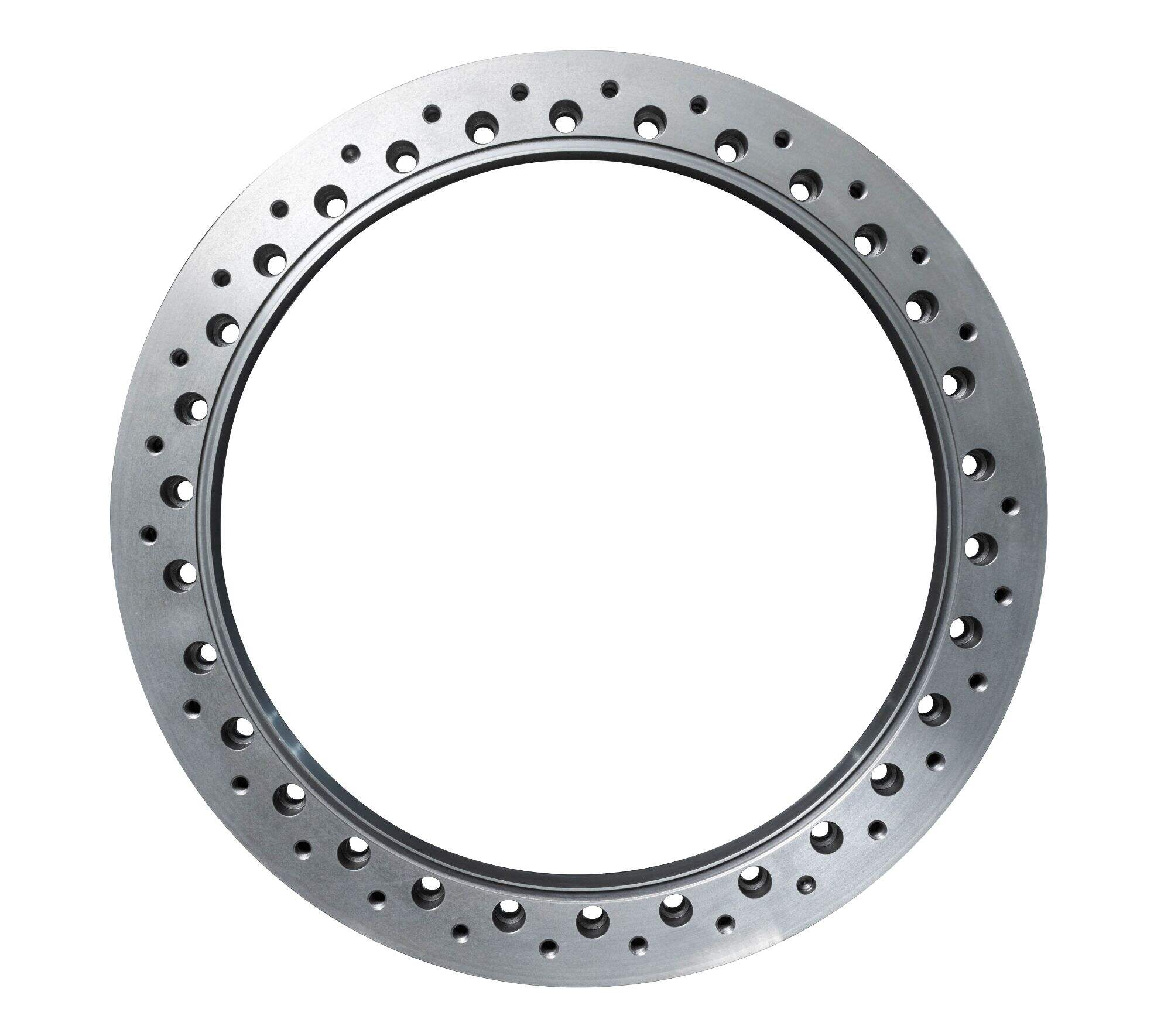

Heat Press Techniques- Platen Shapes and Sizes First They come in all sorts of shapes and sizes so are very adaptable. Square, round, and octagon platens are available. Interchangeable platens allow you to change panels based on the size of clothing that is being printed. This is super useful as it enables you to deal with any sort of cloth, be it a t-shirt or anything else like hoody.

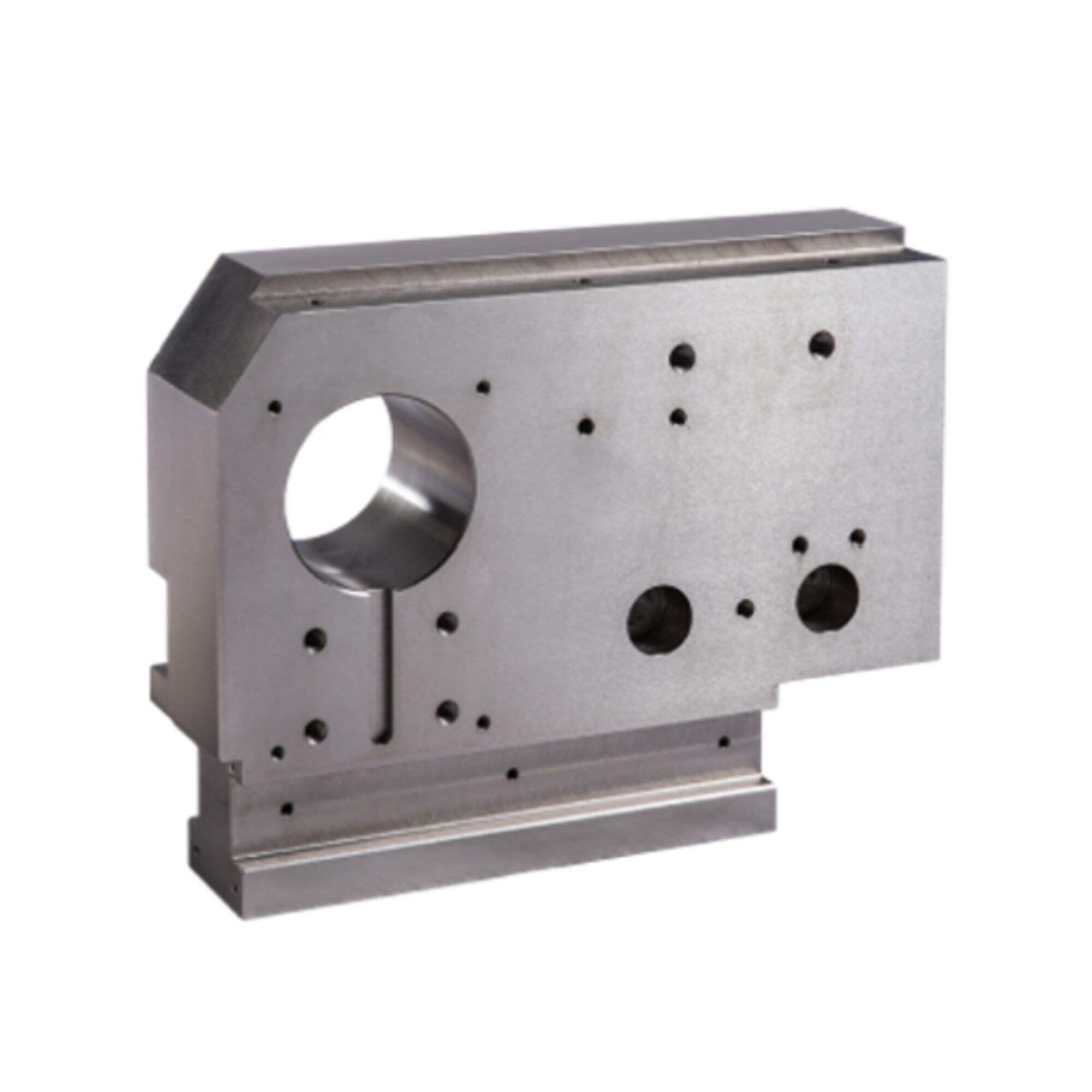

The material a platen is constructed of can be very significant to how the platens work. Aluminum is also used to construct many platens because it help impart plate strength without bending or warping. This is important to ensure that the platen does not wear out after several applications. They consist of other platens, which are made up with teflon-coated steel. Nonetheless, it is a rather useful material in the sense that prevents sticking and makes sure your fabric will not get burned or destroyed while transferring heat It can also help you to decide on the most suitable platen depending on material.

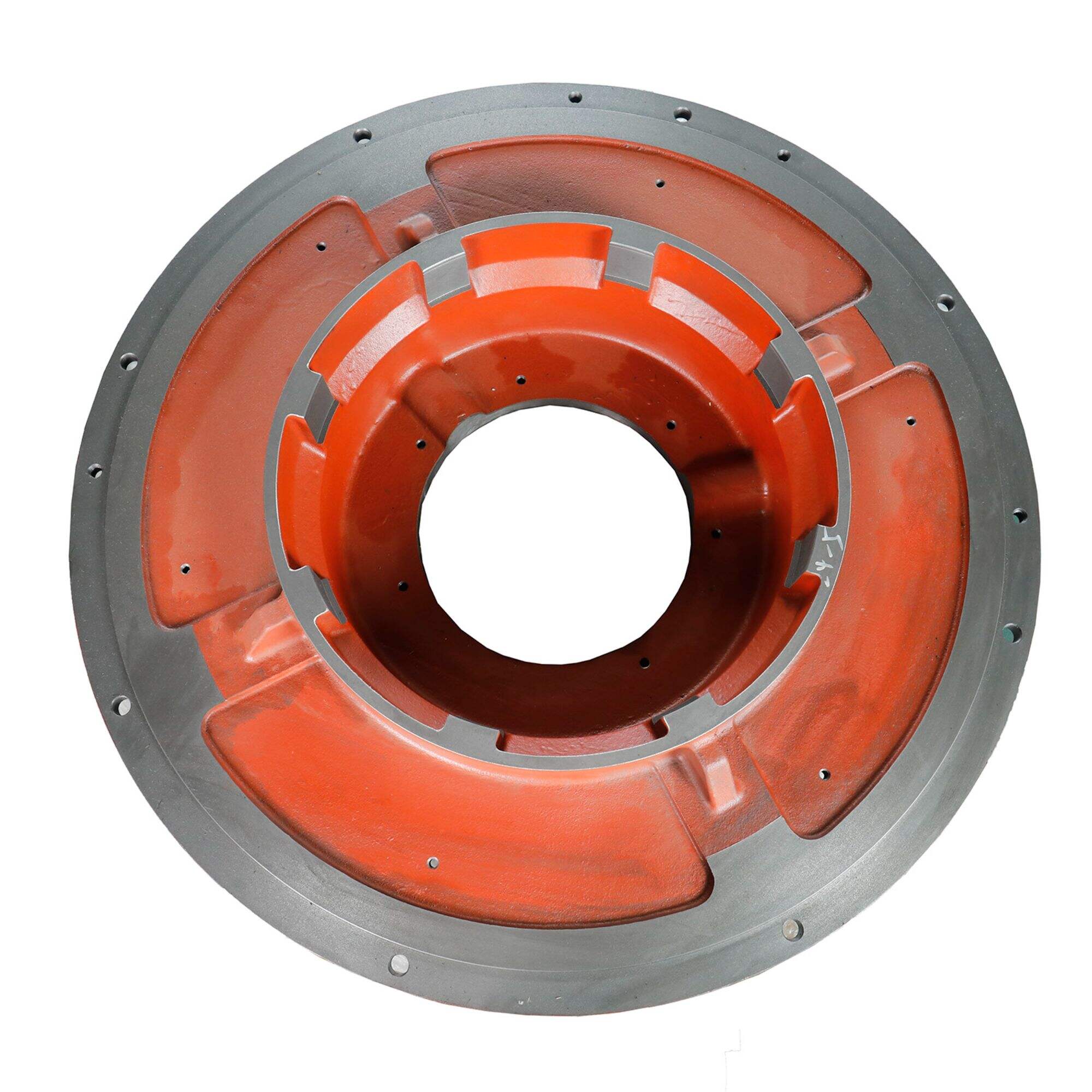

A quality heat press platen makes your life so much easier and gives you an edge in this business. With a heated platen that heats quickly and maintain consistent temperature, you are able to create more designs faster. Thus, the productivity obviously trickles down to getting things done on time. Not only that, but if you vape then it is an investment which will last longer and therefore save your money in the long run as well due to not needing replacing unless on a rare occasion. They are worth the investment in a good platen.

Just like fabric, when you are choosing a heat press platen, you have to consider what YOU need for YOUR projects. A rectangular platen is an excellent choice if majority of your output will be on t-shirts. But if you also print on hats or other types of apparel, then the circular platen would be more versatile.

Great heat transfers can be done through a platen that equally distributes the heating system to prevent materials from burning. The platen itself also has a large say in how this processing goes. Aluminum was good for even heat but stuck horribly, and although the big thing about teflon-coated steel can be sponged out in seconds when cleaning time arrives it did not allow an easy transfer of perfection to plates. This is essential as inconsistent heat can result in incomplete prints.

Heat pressing has become one of the most versatile and could be taken to next level by purchasing some latest platens. If we took some new platens it comes with quick change system to quickly alter between different sizes and shapes. Which means that you will be capable to change projects for different ones, without loss of time. Some may be a fancy mumbo jumbo (right there, right where baby Jesus lost his sandals) magnetic surface. This function makes it easy to position and align your designs, which can facilitate the printing process.

Pingcheng's commitment for honest pricing is founded on years of experience in the industry and knowledge. After we receive the request for quote, we review the drawings and simulate heat press platen as soon as we can, and provide the best solution for your cost.

Pingcheng a total process and lifecycle partners. The shipping of products is just beginning of our partnerships. Our customer service is all about ensuring your satisfactions. Since over 20 years we've provided machine-tooling services and established a strong partnerships with renowned Japanese firms. Our commitments to honesty in pricing is based upon our years experiences in the industry and our heat press platen. We review drawing using special software and presents the best solutions at the most reasonable costs once we have received the request for quotations.

The supply chain and services of Pingcheng are designed to aids clients achieve their goals in business. We heat press platen as well as maximizing the values and life of your manufacturing. PingCheng is a dependable manufacturer you are looking for. We are a suppliers that offers a variety of options.

Pingcheng is now home to more than 20 manufacturing machines and more than 50 skilled technical staff. They heat press platen. Then the products are inspected by Mitsutoyo measuring tools and CMM that are periodically calibrated. Double-checking ensures that the quality of our products precise and stable. Every single component can be traced and monitored during machining and assembly.