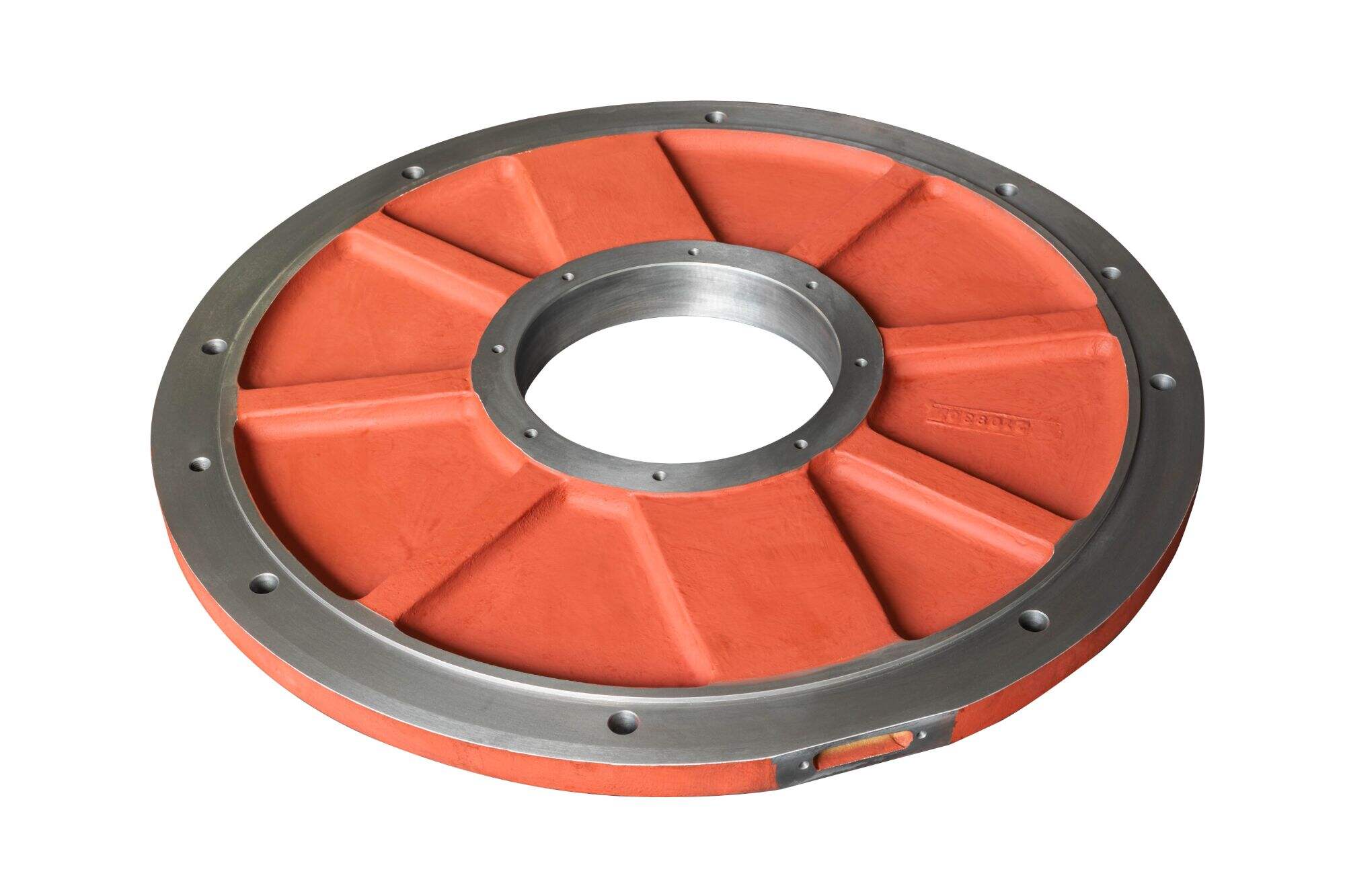

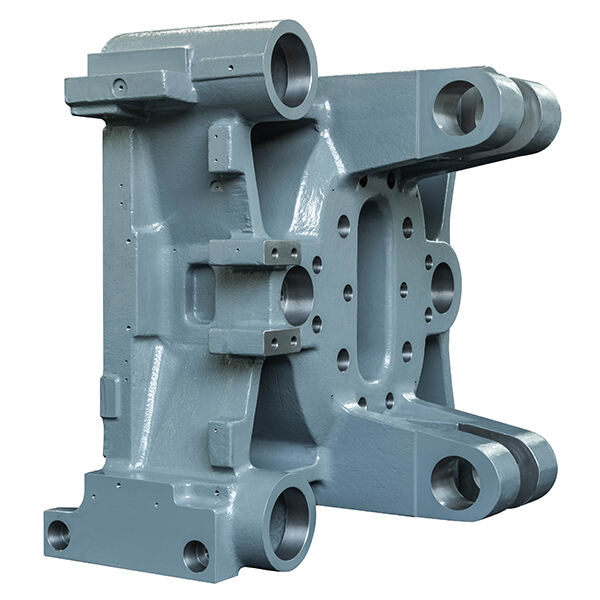

Metal parts are used in making a great deal of products, and there many different ways to make these metal parts. One very common method is pressure die casting, which has been around for over two centuries but is still widely used today — especially with all the new technologies available now that can enhance and optimize this process even further so as to allow it be utilized better than ever before! This process is so fascinating! Essentially, it is melting metal until its in liquid form then pouring that molten metal into a specific container referred to as the mold. It is a mold designed to cast by pressing the metal out of the desired part with high pressure. It then cools off after being filled, solidifies and takes that exact shape of the mold. Which is how super accurate and highly bespoke parts are made.

For manufacturing organisations, there are many benefits of incorporating pressure die casting. To begin with, it is a highly streamlined procedure. One of the great properties of metal is it can be melted and quickly poured into a die or mold, so you are able to turn out thousands upon thousands in no time. This is particularly useful for companies that must manufacture a high volume of parts in short order, such as during peak production periods when demand spikes.

One more important advantage of pressure die casting is that it generates excellent aspects. The high pressure forces the liquid metal into all nooks and crannies of that mold. Therefore, the parts that produced are very accurate and detailed. Uniform And Reliable MachiningThis is of particular importance to businesses that require like for like parts Made To Order From Pinterest — which need to be uniform, accurate and consistent throughout. When Audi creates such high end engines, they like to make sure just every little part is right and Pressure die casting helps them accomplish that.

Last but not least, always benefits from the sheer cost effect of pressure die casting. There is an upfront cost to own the deep draw tooling that will make this part, and all of its related equipment; however once you have it set up, you can run large production volumes for a relatively low price over time. This assistance has kept the costs low for raising companies and it is quite crucial to survive in market where survival of fittest rule applies.

Experienced pressure die casting companies offer great customer service in addition to their skill, experience and equipment. They partner with their clients to completely understand what are they expecting and help them out on each step, as much as you have questions. Since there is such a personalized working relationship, this ensures that all of their customers are happy with the parts they receive in return for forming an even tighter partnership.

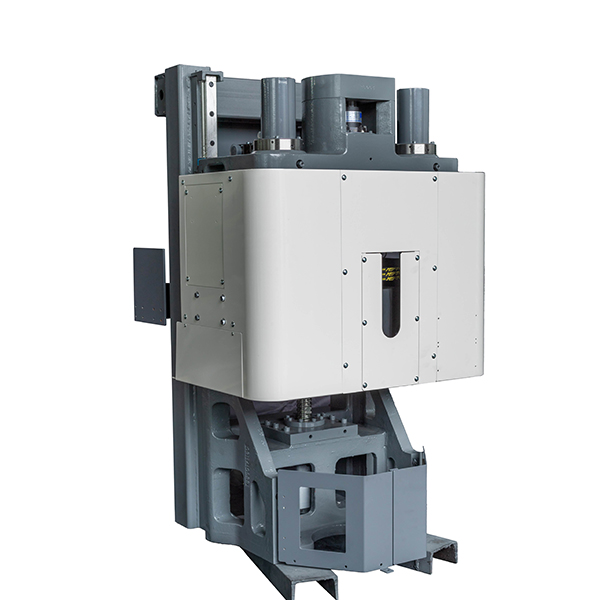

As with any else in the industry, pressure die casting is always evolving and improving. AutomationMaker kits and THE NEW INDUSTRY -ESTRONG suitable for one of the biggest trends in industry you know against automation include robotics, but- These processes can reduce the time involved in pressure die casting and also provide better quality control leading to end products of higher precision. This will allow companies to produce parts more quickly and at a higher quality.

Last but not least, the pressure die casting industry is seeing a shift towards sustainability. Businesses everywhere are striving to effectively reduce their waste and enhance the impacts they have on our environment. This could mean using recycling programs to reuse waste materials that result from the pressure die casting process, or finding other unique ways to repurpose them. With an eye to sustainability, organizations can meet the scale needed for production without sacrificing a greenfootprint.

Pingcheng is a full-service and pressure die casting companies. The shipping of our products is just the beginning of our partnership. Our customer service about ensuring your satisfactions. For more than 20 years we've provided manufacturing services and have built close collaboration with well-known Japanese companies. Pingcheng's adherence to truthful pricing is based our decades of experiences in the industry and understanding this sector. We analyze the drawing in special software and present the best solution at an affordable costs once we have received an inquiry for quote.

Based on pressure die casting companies and a deeps understanding of the business, Pingcheng dedicated to providing its customers with a fair prices. When we receives a an inquiry for quotes, we look at the drawings and simulates using special software immediately, and offer the most effective solutions with a fair costs.

Pingcheng has now more than 20 manufacturing machines and pressure die casting companies with years of experience. They aim at providing high quality. They then inspect the products by Mitsutoyo measuring tools and CMM that are calibrated on a periodic basis. Double-checking ensures that the product's quality precise and steady. Every key component is traceable and controlled during the machining process and assembly.

The supply chain and services of Pingcheng are designed to aids clients achieve their goals in business. We pressure die casting companies as well as maximizing the values and life of your manufacturing. PingCheng is a dependable manufacturer you are looking for. We are a suppliers that offers a variety of options.