Excited to know about the clamp injection molding? This awesome process is responsible for many items you use on a daily basis! Whether you are dealing with a toy that you play around on or a toothbrush for cleaning your teeth, clamping injection molding special together is how many of these things are done.

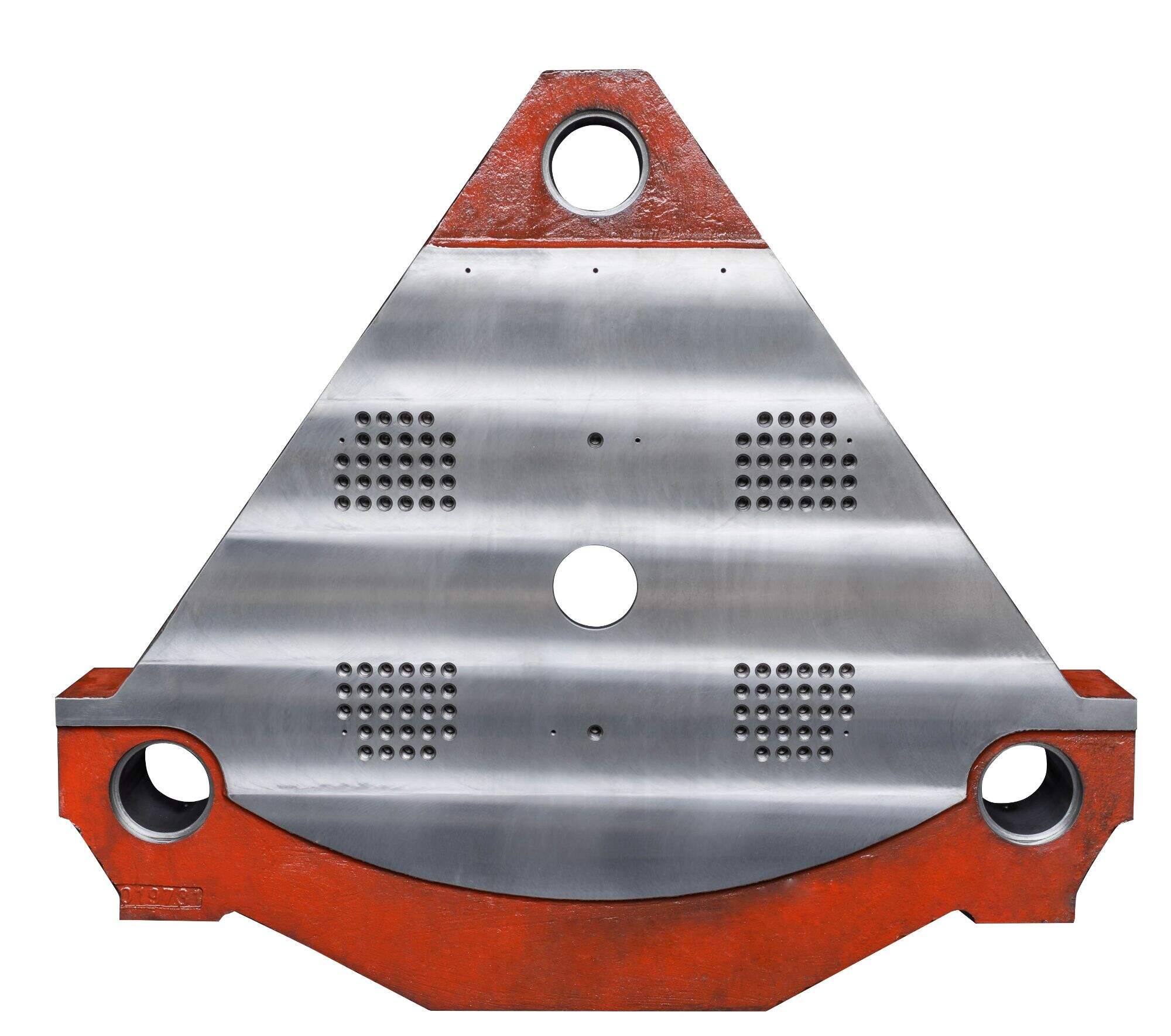

Clamp injection molding is a unique process that involves creating plastic products. Pellets are the convenience and they're plastic, meet thousands of small pellets. After which they are heated and melted into a thick liquid. The melted plastic then is injected into the die. A mold is a dual type special tool (two parts that should fit together) The molten plastic is injected into the mold, this fills the space and takes on the shape of your part. Once the plastic has cooled, the two halves of die are separated and your new molded piece can be ejected!

A great advantage of clamp injection molding is that it can produce loads and piles of items in less time. This is important because in manufacturing large numbers of the same item - think toys or containers for instance- speed matters. Not only that, but this process saves money since the molds are reuseable. This means that the company can reproduce hundreds of thousands or millions (depending on how robust their molds are) plastic item many times, without spending anymore more money in making new molds from scratch each time they want to make more.

If you need something to be produced out of plastic for your business or project, it is incredibly vital that clamp injection molding is taken under consideration. Not sure I'd do that for a single item but its could be great if you have to make many items. But make no mistake, if you are only going to create small numbers of an item here or there- this may not be for your best interest. Still, you may want to think about mold cost as well. On the other hand, creating a new mold for each item you only take few off would make it insanely expensive.

There are several important steps in the process of clamp injection molding that need to be followed carefully. Plastic pellets are loaded into an injection molding machine. This equipment warms up the pellets for full melting. The plastic is injected into the mold after being melted. Once the mold has been filled by plastic, it must cool. Once cooled, the two halves of the mold are separated to release a new plastic object. Every one of these steps is crucial to ensure the high caliber plastic product.

Here are some of the most important steps to treat clamp injection molding that will help you create high-quality plastic parts: The design of the mold is also particularly important. This is essential to allow the molten plastic to happily flow through every nook and cranny of your mold. The second part, the machine has to be dialed in correctly for how much plastic is used and when it shoots into The faster rate. Finally, once this plastic item is made, it should lamely be examined for each new thing created. This ensures it complies with all the relevant quality standards.

Our customer services focuses your satisfaction. We've been providing the machining services and clamp injection molding with industry-renowned Japanese businesses for more than 20 years. Based on decades experience and knowledge of this industry, Pingcheng is dedicated to giving customers honest prices. Once we get a quotation requests, we look at the drawings and simulates using specialized software immediately, and offer the best solution with proper prices.

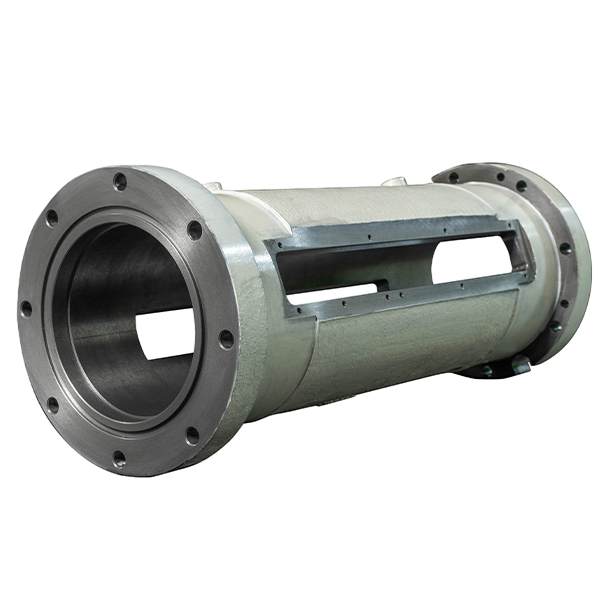

Pingcheng is now clamp injection molding and 50 highly skilled technical employees. They committed to providing highest quality. Mitsutoyo's measuring instruments and CMM are calibrated regularly. The double-checking keeps quality reliable and accurate. The machining and assembling of all keys components are easily traceable and controlled.

Pingcheng's clamp injection molding is founded on decades of industry experience and a deep understanding. After we receive quotation requests, we examine the drawing and simulate in specialized software right away, and then provide the most effective solution with a fair price.

Pingcheng's clamp injection molding and services are designed to helps customers meet their goals for business. We are focused on expanding and increasing the potential and lifespans of your productions. PingCheng is a dependable producers you are looking for. We are a suppliers that provides opportunities.