Vertical injection molding is a process to manufacture plastic parts which are generally used in domestic appliances. This entails a process that uses a highly advanced machine which melts plastic pellets and feeds them into an open mold. The mold comes in many shapes: from gears to toys to medical devices. As the melted plastic cools and becomes hard, it is released from within this mold.

PrecisionOne of the key benefits that vertical injection molding offers is precision. This means that the plastic is injected directly downwards so that even the smallest mold crevices can also be filled. This allows for very complex and detailed features to be manufactured into parts. In addition, this method is one of the most efficient and can produce a lot in very little time. Conversely, vertical injection molding requires a large sum of capital to purchase both the machine and molds, which is better for mass production situations.

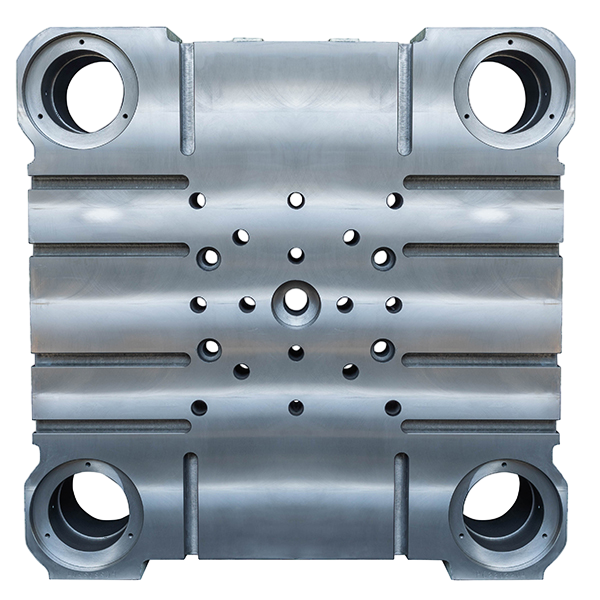

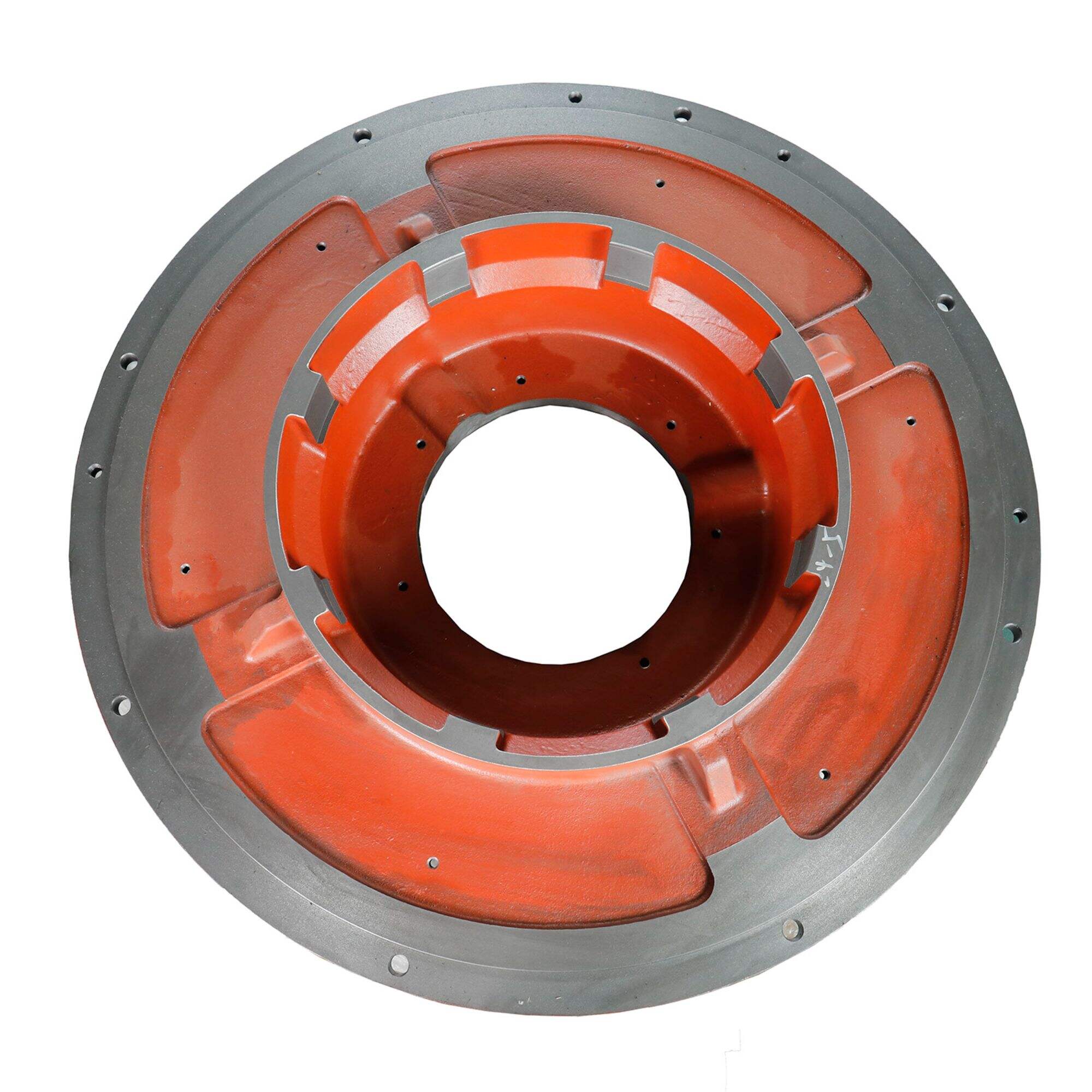

Vertical Injection Molding Machine is tailored for manufacture of different kinds of items - right from gears to medical devices. The machine has two main components: an injection unit and a clamping unit This unit heats up the raw material and injects it into the cavities, while a hydraulically actuated clamping unit holds it in place as soon as possible until molding has solidified. The clamping unit then moves to the open position so that final part can be ejected from the mold.

Vertical injection molding is known for making large quantities very quickly. Because the plastic was injected with a vertical injection of GEF, even if there is very little clearance it allowed to be filled and sealed by mold. After the machine is configured, it can operate independently and remove operators for other presses. Year after year, this efficient manufacturing process keeps production worthwhile.

Due to the nature of injection mold manufacturing, intricate components very often are made form vertical injection molding. Vertical injection of plastic means that these difficicult mold spaces can be filled which may otherwise fail if this cannot follow. Additionally it is programmable for complex shapes and layout, which permits regular device manufacturing with a excessive degree of element.

The Cost And Time Savings Of Vertical Injection Molding Over The Traditional Ways

Vertical molding saves tremendous times and costs compared to the conventional traditional ways of molding. Plastic is injected on a vertical path to fill the mold which has details and set up for explusive shapes with precision. On top of it all, the machine can be set to run automatically after being setup increasing process efficiency. The freedom to programme the machine with specific designs also means that plastic wastage is vastly reduced.

In a word, the vertical injection molding is good for large production of plastic parts. Its ability to produce large amounts of almost any moldable design quickly and accurately, is invaluable. While this may be an expensive investment in the beginning, it often pays off due to these parts being produced at such a quality and precision.

Pingcheng is a full-service and vertical injection molding. The shipping of our products is just the beginning of our partnership. Our customer service about ensuring your satisfactions. For more than 20 years we've provided manufacturing services and have built close collaboration with well-known Japanese companies. Pingcheng's adherence to truthful pricing is based our decades of experiences in the industry and understanding this sector. We analyze the drawing in special software and present the best solution at an affordable costs once we have received an inquiry for quote.

Pingcheng currently has more than 20 manufacturing facilities and 50 highly skilled technical employees. They vertical injection molding. Mitsutoyo's measuring instruments and CMM are periodically calibrated. The double-checking keeps our quality steady and accurate. The machining and assembly of all key parts are tracked and controlled.

Pingcheng is committed to helping customers achieves their business goals through our vertical injection molding and service solutions. We concentrates on helping you extend the life and values of your production. PingCheng is the dependable manufacturers you're looking for. We are a company that delivers options.

Based on decades in experience and a deep understanding of the industry, Pingcheng is dedicated to offering customers a fair price. When we vertical injection molding, we examine the drawings and simulate using specialized software right away, and then provide the best solution for your price.