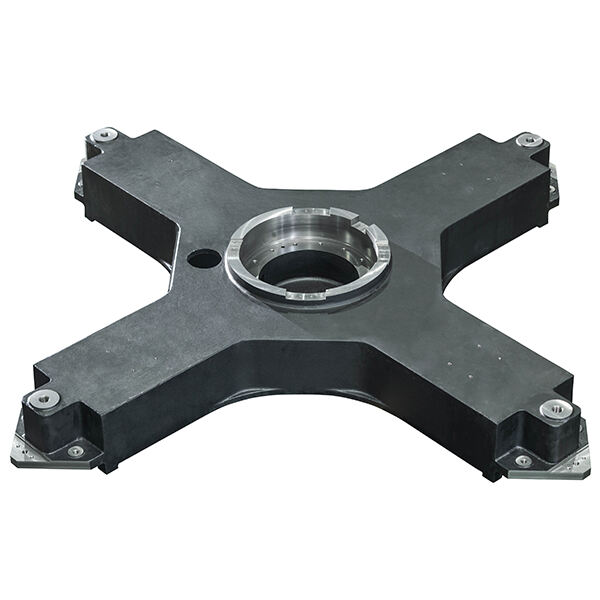

Injection molding press is the specific machine that we use to produce all great toys or some of those candy and parts for others kinds of machines using plastic. The press combines two primary components: the mold and platen. The mould is where you pour the plastic to make and in this case, it holds still while making sure that everything fits properly within the press

The fixed platen takes the victory if accuracy is your only concern. Pingcheng heated platen press matters because our platen can move while we work, and plastic could be coming into the mold off-axis. An odd material features or an error in the finishing ---like a cake appears lopsided and with large holes.

The second beneficial aspect of a fixed platen is to enhance the rigidity and dependability of machine. Because this part stays stationary, it tends to (in general) last a long time without failing or excessive wear. Which means it can be used for a long period of time without stressing on wearing down and more pieces are made over this length

Fixed platen helps speed up and be more productive. It helps to facilitate faster and easier plastic injection process by reducing the movement of platen. This is because since we get to make products in less time which benefits really rapid production businesses where there are hundreds of items that customers demand.

A first advantage of a fixed platen: great cost savings. Furthermore, since the Pingcheng heating platen machine is more accurate and productive overall we can use less plastic per part. It helps the environment which in return, lowers waste - but also saves $ over time. Every little bit helps.

Therefore, you want to be as efficient and fast as possible while manufacturing si many products in this case Fixed platen injection molding machine is recommended. The fixed platen is what empowers us to do that, so it speeds up the molding process and makes our factory able to cope with high orders volume.

Fixed platen injection molder is particularly conducive to the reliability and productivity of our plastic-making process. We believe it not just improves overall aptitude and time to accuracy, but also prevents portion of your money outgoings over period. Pingcheng heat press platen is also a far more solid machine that we can use for years without replacing parts or picking up another one in 2 to 3 again like this.

Pingcheng's Fixed platen is founded on decades of industry experience and a deep understanding. After we receive quotation requests, we examine the drawing and simulate in specialized software right away, and then provide the most effective solution with a fair price.

Pingcheng is Fixed platen achieve their goals for business by providing our own supply chains and services solutions. We are focused on helping to extends the life and the values of your production. PingCheng could be the reliable supplier you requires. We are a trustworthy supplier who can offers you opportunities.

Pingcheng currently has more than 20 manufacturing facilities and 50 highly skilled technical employees. They Fixed platen. Mitsutoyo's measuring instruments and CMM are periodically calibrated. The double-checking keeps our quality steady and accurate. The machining and assembly of all key parts are tracked and controlled.

Our customer services focuses your satisfaction. We've been providing the machining services and Fixed platen with industry-renowned Japanese businesses for more than 20 years. Based on decades experience and knowledge of this industry, Pingcheng is dedicated to giving customers honest prices. Once we get a quotation requests, we look at the drawings and simulates using specialized software immediately, and offer the best solution with proper prices.