Injektioformiautomaatti on tarkka kone, jonka käytämme tuottamaan kaikki hienot lelut tai jotkin niistä makeeista ja osista muidenkintoisten konesarjojen käyttöön muovilla. Kone yhdistää kaksi pääasiallista komponenttia: muovin ja patereen. Muovi on se, johon keitämme muovia tekemiseen, ja tässä tapauksessa se pysyy paikoillaan samalla, kun varmistetaan, että kaikki mahtuu oikein paineen sisään.

Kiinteä patara voittaa, jos tarkkuus on ainoa huolenaiheesi. Pingcheng lämpötynnyri on merkityksellistä, koska pataramme voi liikkua työskentelyä varten, ja muovi voi tulla muovimalliin keskipisteestä poikkeavasti. Epäreilu materiaali tai virhe valmistuksessa --- kuten kakku, joka näyttää vinottavalta ja suurilla aukkoilla.

Kiinteän pöydän toinen hyöty on parantaa koneen joustavuutta ja luotettavuutta. Koska tämä osa pysyy paikoillaan, se kestää yleensä kauan ilman epäonnistumista tai liiallista kuljetta. Tämä tarkoittaa, että sitä voidaan käyttää pitkään ilman, että se aiheuttaa lisää kuljetta, ja enemmän kappaaleita voidaan tuottaa tämän ajan kuluessa.

Kiinteä pöytä auttaa nopeuttamaan ja tekemään tuotantoa tehokkaammaksi. Se helpottaa nopeampaa ja helpompaa muovinjoonnuksen prosessia vähentämällä pöydän liikettä. Tämä johtuu siitä, että tuotteet voidaan valmistaa lyhyemmässä ajassa, mikä on erityisen hyödyllistä nopeassa tuotannossa, jossa asiakkaat vaativat satoja esineitä.

Kiinteän pöydän ensimmäinen edut: suuret kustannussäästöt. Lisäksi, koska Pingcheng lämpöalusta kone on tarkempi ja tuottavampi yleisesti, joten voimme käyttää vähemmän muovia osasta. Se auttaa ympäristöä, mikä puolestaan vähentää jätettä - mutta säästää myös rahaa ajan mittaan. Joka pieni apu auttaa.

Siksi haluat olla mahdollisimman tehokas ja nopea, kun valmistat niin monia tuotteita tässä tapauksessa kiinteän pohjan muovauskone suositellaan. Kiinteä pohja antaa meille mahdollisuuden tehdä sen, joten se nopeuttaa muovausprosessia ja tekee tehtaatamme kykeneväksi käsittelemään suuria tilausten määriä.

Kiinteän pohjan muovauskone on erityisen edistyskykyinen liittyen luotettavuuteemme ja tuottavuuteemme muovien valmistusprosessissa. Uskomme, että se ei vain paranna kokonaisvaltaista osaamista ja tarkkuutta ajan kuluessa, mutta myös estää osan rahojesi menoja pitkällä ajanjaksolla. Pingcheng lämpöpainoplaatti on myös paljon vankempi kone, jonka voimme käyttää vuosikymmeniä ilman, että tarvitsemme vaihtaa osia tai hankkia uuden koneen 2-3 vuoden sisällä kuin tässä.

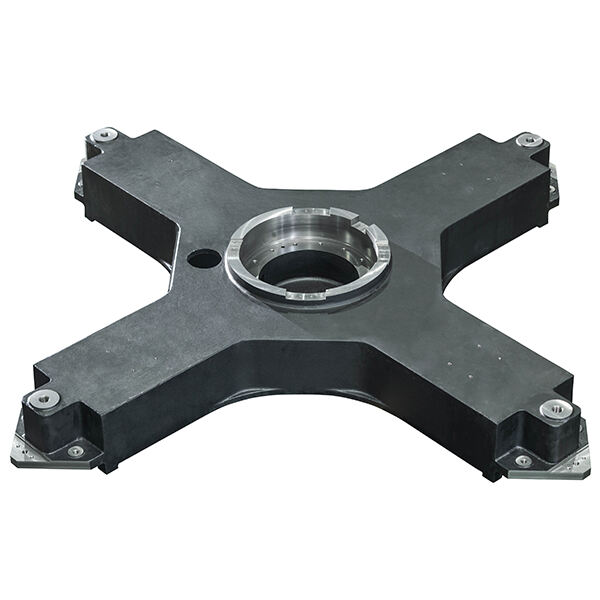

Pingchengin kiinteä plaatteinen perustuu vuosikymmeniin teollisuuskokemukseen ja syvään ymmärrykseen. Kun vastaanotamme tarjouspyyntöjä, tarkastamme piirrustuksen ja simuloidumme sen erikoisohjelmistossa heti, ja annamme sitten tehokkaimman ratkaisun reilulla hinnalla.

Pingcheng on kiinteä laatta, joka saavuttaa liiketoimintatavoitteensa tarjoamalla omat toimitusketjunsa ja palveluratkaisunsa. Keskitämme toimintamme siihen, että autamme pidentämään tuotannon käyttöikää ja arvoa. PingCheng voi olla luotettava toimittajasi. Olemme luotettava toimittaja, joka tarjoaa sinulle mahdollisuuksia.

Pingchengilla on tällä hetkellä yli 20 valmistustoimintaa ja 50 erittäin taitavaa teknistä työntekijää. He hoitavat kiinteät plaatteet. Mitsutoyon mittaussäädöt ja CMM kalibroidaan jatkuvasti. Toinen tarkistus säilyttää laadunme vakiona ja tarkkana. Kaikkien avainteiden moottorimaisennus ja montausrakenteet seurataan ja ohjataan.

Asiakaspalvelumme keskittyy tyytyväisyyteenne. Olemme tarjoaneet koneistuspalveluita ja kiinteitä kylvölevyjä teollisuudessa tunnetuille japanilaisille yrityksille yli 20 vuoden ajan. Vuosikymmenten kokemuksen ja alan syvällisen osaamisen perusteella Pingcheng pyrkii tarjoamaan asiakkailleen reiluja hintoja. Kun saamme tarjouspyynnön, tarkastelemme piirroksia ja simuloidaan niitä heti erityisohjelmiston avulla sekä tarjoamme parhaan ratkaisun sopivilla hinnoilla.