Heating platen (a heated flat tool that radiates very high temperatures when in use) They are comprised of various kinds of materials that can range from metal, silicone or even glass. Any objects that are put on top of the platen get hot, because it heats up and passes heat to any other materials above this surface. This is a necessary step in order to give the materials their required shape and dimensions.

Heating platens are commonly used in the production of a variety of materials, including plastics and rubber but also metals. As an instance, in plastic molding the heated platen helps to give shape to plastics for various products like containers or toys. Rubber molding is used to form rubber into tires, or seals. Heating platens are used, which helps to expedite the entire process and enables workers in producing numerous units within a shorter span of time.

Time Reduction- This is one of the major reasons that because the heating platen lets product being prepared relatively quickly. The quick heat can burn material to high temperatures immediately which fewer production in less time of many items. Especially for customer-obsessed businesses in this fast-paced world, we need to respond very quickly.

An additional benefit of the use of heating platens is that they maintain precision within your manufacturing process. The heating plate furnishes a stone so hot that any actual arrangement of the material format in home altro flooring comes out right. This eliminates waste by producing less scrap and results in improved products that better meet the need of customers.

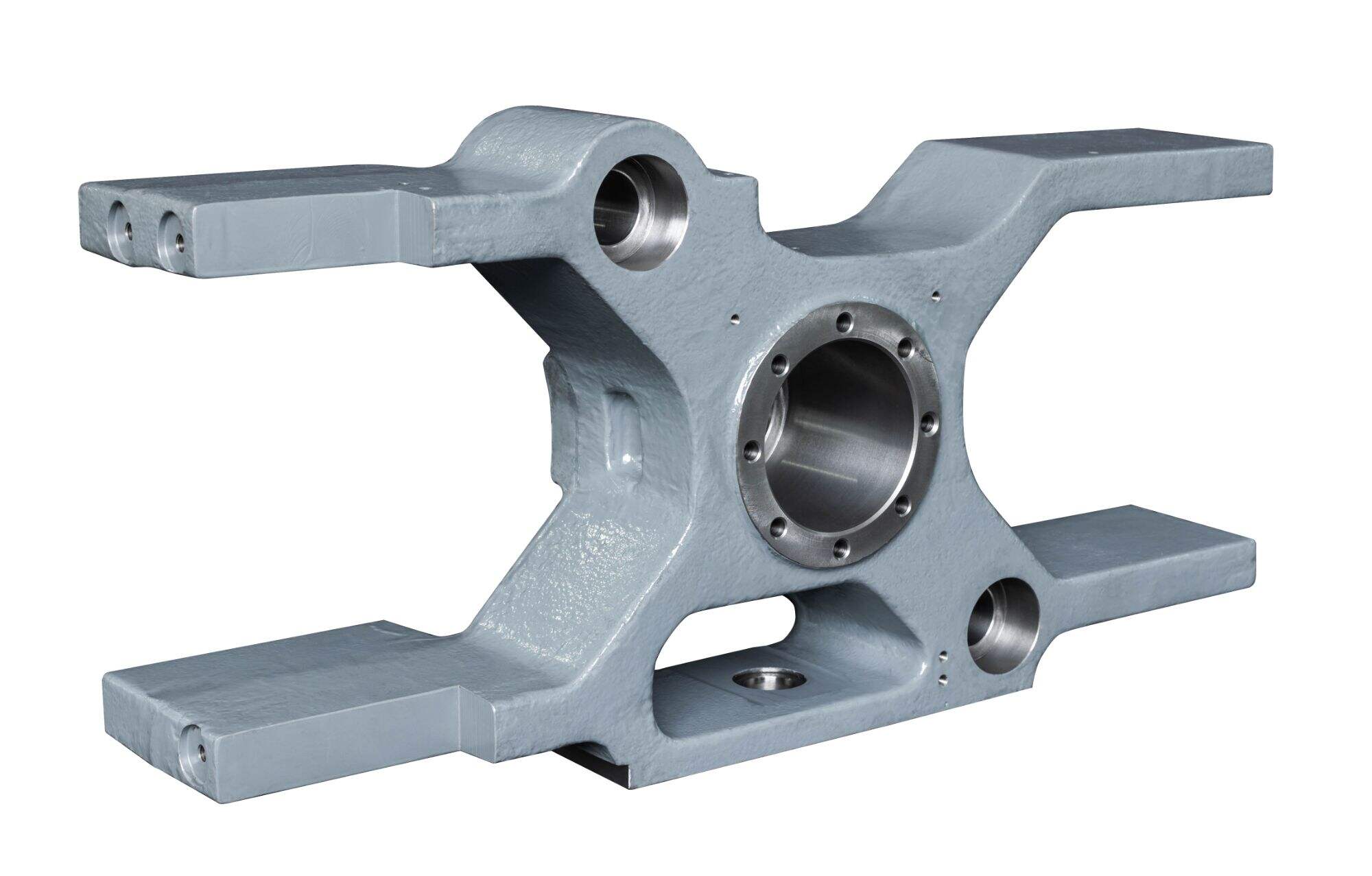

There are many more types of heating platens, the two examples shown will be electric and oil-heated with a band heater (Figure 13), there also is water-cooled plattes which have coolant running through them. There are pros and cons for each. Electric platens are a breeze to use and heat up quickly but oil-heated ones offer more consistent heating. Before using any of them, your needs to be considered into account so that you select the proper platen for the product.

Taking care of your heating platen from time to time is something that you should not ignore if you want it working properly. This includes regular cleaning of the platen surface to avoid accumulation of dust and debris which can inhibit precision. Check the wiring and heating elements for signs of corrosion or damage, as well. It is important to replace any broken parts immediately, as this can affect performance.

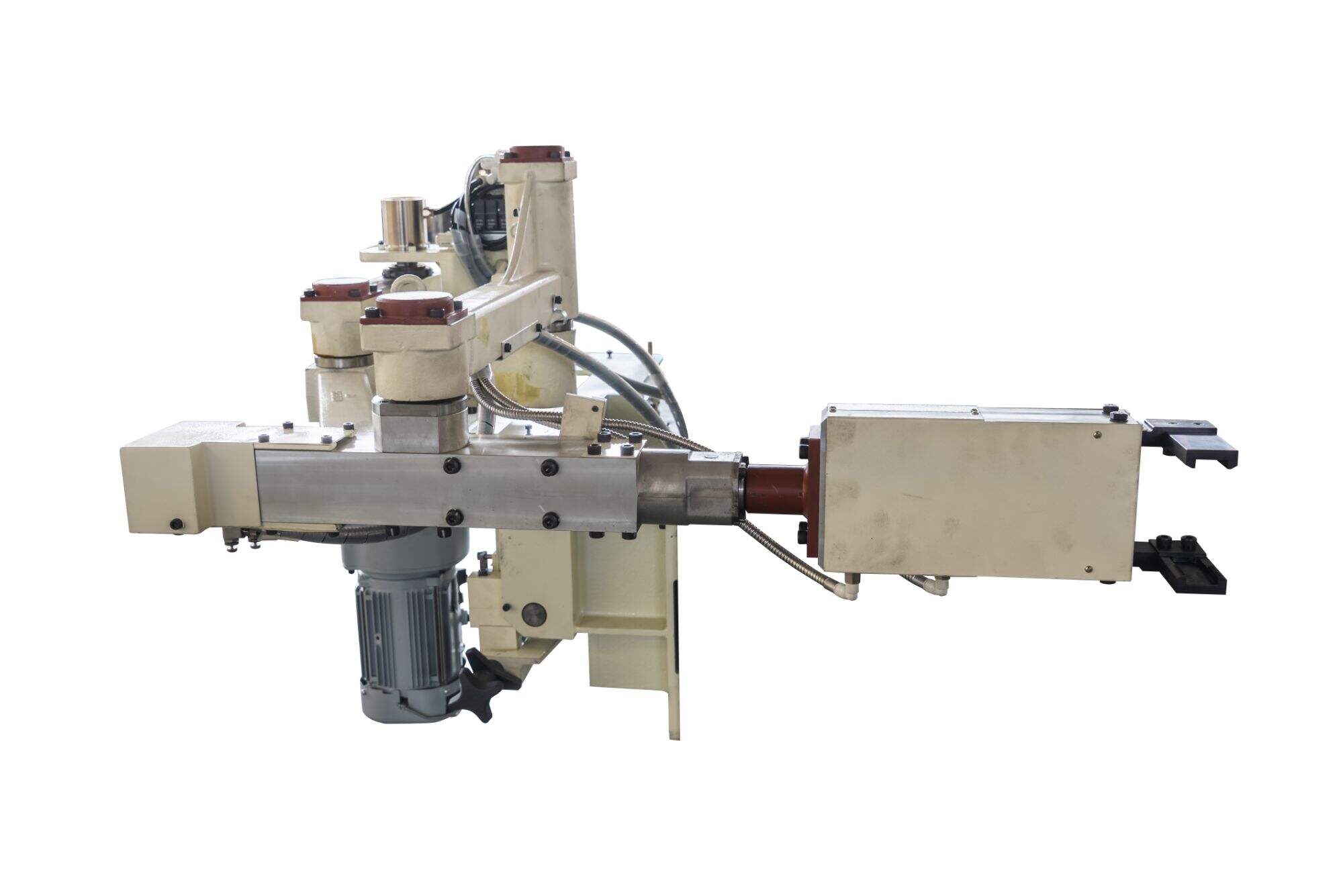

Since then, heating platens have been upgraded due to technological advances. These improvements benefit the accuracy and energy efficiency of heating platens in production applications. These advances include more precise temperature control systems, high-performance platen materials and computer controls capable of continuously monitoring and adjusting heat processes.

The supply chain and services of Pingcheng is designed to assist customers reach their business goals. We focus on extending and heating platen. PingCheng is the reliable manufacturer you're looking for. We are a partner which delivers options.

Pingcheng's commitment for honest pricing is founded on years of experience in the industry and knowledge. After we receive the request for quote, we review the drawings and simulate heating platen as soon as we can, and provide the best solution for your cost.

Our customers service focuses your satisfaction. We've been providing machining services and heating platen with industry-renowned Japanese companies for more 20 years. Based on years of experiences and knowledge of the industry, Pingcheng is dedicated to offering our customers an honest price. We evaluates the drawings using special software and present the best solutions at the most reasonable costs once we have received requests for quotations.

Pingcheng today has more than 20 manufacturing facilities and more than heating platen. They aim at providing high quality. Mitsutoyo's measuring devices and CMM are regularly calibrated. Double-checking helps keep the accuracy of our products and steady. Every single component can be traced and monitored during machining and assembly.