A mould clamp is a beneficial tool that you want to have on hand because it holds the two parts of the mold together while creating plastic items. And the process to make these items has a lot of importance which should be completed properly. In today's article, we will cover the specifics of mould clamps in detail to educate you on what they are and how it works and why it is essential for production.

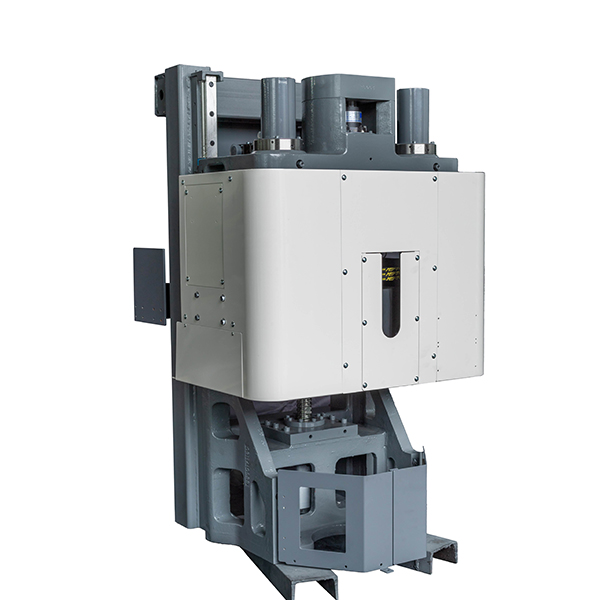

Previously, it was a time-consuming and tedious process to clamp the moulds. But this slow process delayed production and made it more difficult for factories to get their work done. As for now due to the advanced technology, clamping of molds has become much faster and make it more efficient. Currently, many mould clamps are designed to operate very quickly with the ability to grab and drop a mold in short time periods. These modern clamps have been put together by some cool parts and fasteners that save time for anyone involved in the production.

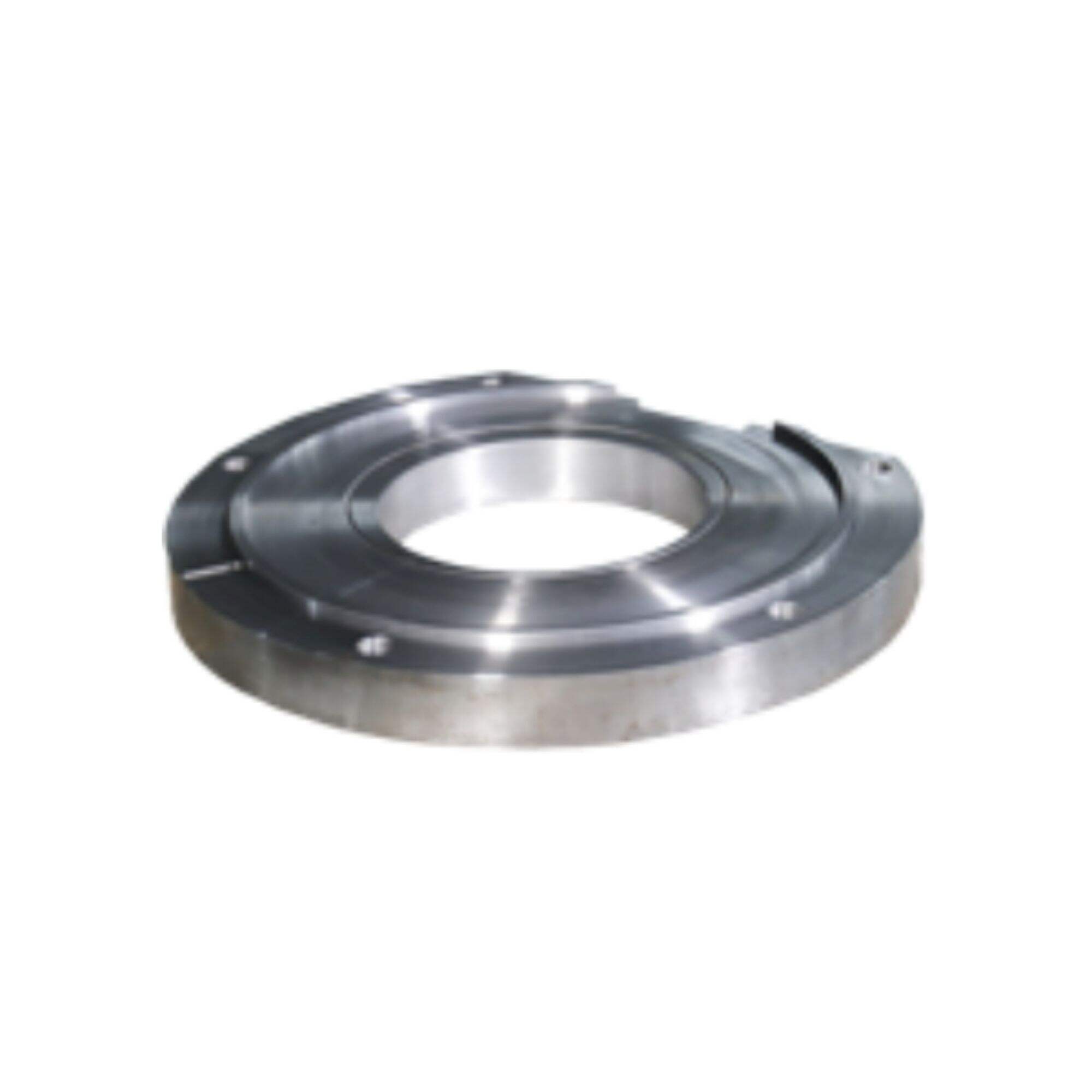

The mould clamps of good quality are very essential to manufacture plastic items in an effective way. During the injection process, they keep it tight. Mould clamps that are made up of high-quality stainless still steel which ensures it is strong and durable so does not get damage easily even under toughest working conditions. When you are making top quality plastic items, every time when produced then it is necessary that mould clamps which work smoothly and effectively be used.

When the moulds are clamped, plastic should be injected well. The mould for this is not 100% secure, so if the resin were to spill out of one side (the bottom on its right in my picture above) where both sides are completely smooth surfaces at different angles, there would be very little stopping it from going beyond that edge and overfilling. Quality should be top-notch regardless, and reliable mould clamps ensure this level of precision is achieved at all times. We use these precision-crafted clamps ourselves and they have the thumbs up from many professionals. There are many reliable mould clamps that you can get but for those who want the best results, it is a wise decision to buy from established brands which well-experienced people recommend.

The production time was 30% to 50% faster than before since new technology had completely improved the clamping way. In most cases, contemporary mould clamps are engineered for fast and extra precise end results so manufacturers can make more products within time. Types of clamps range from electric, hydraulic and pneumatic to mechanical. They all come with their own benefits as well as negatives. Choose the right mould clamping technology and enjoy ideal production quantity as well offer excellent quality products to your target customers.

And clamps are very important. You need solid and easy to use ones in yousetup so keep your moulds safe! Easy to manipulate clamps, both for manufacturing time savings and operator safety but also protects mould from accidental mishandling during the closure phase. It is why the clamps are made from stubborn material which they can use in tough conditions of moulding. Ultimately, the right mould clamp depends on specific requirements you might have for production. Always make sure to find clamps that are trustworthy in addition to easy-to-hold, otherwise your shape is definitely possible take from the particular plastic injection process.

Pingcheng is a full-service and mould clamp. The shipping of our products is just the beginning of our partnership. Our customer service about ensuring your satisfactions. For more than 20 years we've provided manufacturing services and have built close collaboration with well-known Japanese companies. Pingcheng's adherence to truthful pricing is based our decades of experiences in the industry and understanding this sector. We analyze the drawing in special software and present the best solution at an affordable costs once we have received an inquiry for quote.

The supply chain and services of Pingcheng are designed to aids clients achieve their goals in business. We mould clamp as well as maximizing the values and life of your manufacturing. PingCheng is a dependable manufacturer you are looking for. We are a suppliers that offers a variety of options.

Pingcheng is now home to more than 20 manufacturing facilities and 50 experienced technical workers. They mould clamp. Then, the product is inspected by Mitsutoyo measuring instruments and CMM that are periodically calibrated. Double-checking makes sure that the quality of our products precise and steady. The machining and assembly of all the key components are controlled and traceable.

Based on decades in experience and a deep understanding of the industry, Pingcheng is dedicated to offering customers a fair price. When we mould clamp, we examine the drawings and simulate using specialized software right away, and then provide the best solution for your price.