A linear Rails & Slides in the large world of manufacturing. These are key parts because they allow them to get around with ease in a straight line, like little machine train tracks. Today, I would like to discover more about linear rails and slides in the intriguing manufacturing world.

Let Us See How Linear Rails & Slides Enable Machines to Make Accurate Movements

In the world of manufacturing, machines are mechanically programmed to do a repetitive and uniform action with acute accurate results. Take, for example the creation of a paper cup. The paper must be cut and formed to delicate perfection by the machine. This is where the linear rails and slides fit in, which are responsible for guiding its movements accurately to move correctly. These constituents help ease manufacturers to improve the efficiency, save time and reduce wastage of material which is essential for productivity increase.

Similarly, as fastidious preparation is mandatory prior to cookie baking - accurately placing of linear rails & slides simplifies machine processes. These components come pre-assembled and make it very simple for a production line worker to setup and maintain the unit in next no time. Furthermore, their sturdy build means lower replacement or repair rates freeing up factory personnel to carry out other important tasks on the production line.

Linear rails, slides are utilized in numerous industries ranging from the automotive to aerospace and medical equipment manufacture. These parts used to ensure the uniformity of car components in automotive. In the aerospace and defense fields, they are widely used to move precision instruments requiring extreme care. The medical sector also uses linear rails and slides to manufacture intricate surgical devices which have an accuracy of few micrometers.

These Linear Rails & Slides Are an Integral Part of Industry 4.0 Automation

Recently, the world has shifted towards Industry 4.0 - with an increased use of automation and data exchange in manufacturing technologies including Internet Of Things, cyber-physical systems, cloud computing etc. In fact, linear rails and slides are central to a number of Industry 4.0 devices that enable machines to perform tasks all on their own. The automation not just brings down human error possibilities but at the same time, it enhances factory operations to higher efficiency and productivity by consuming resources more efficiently.

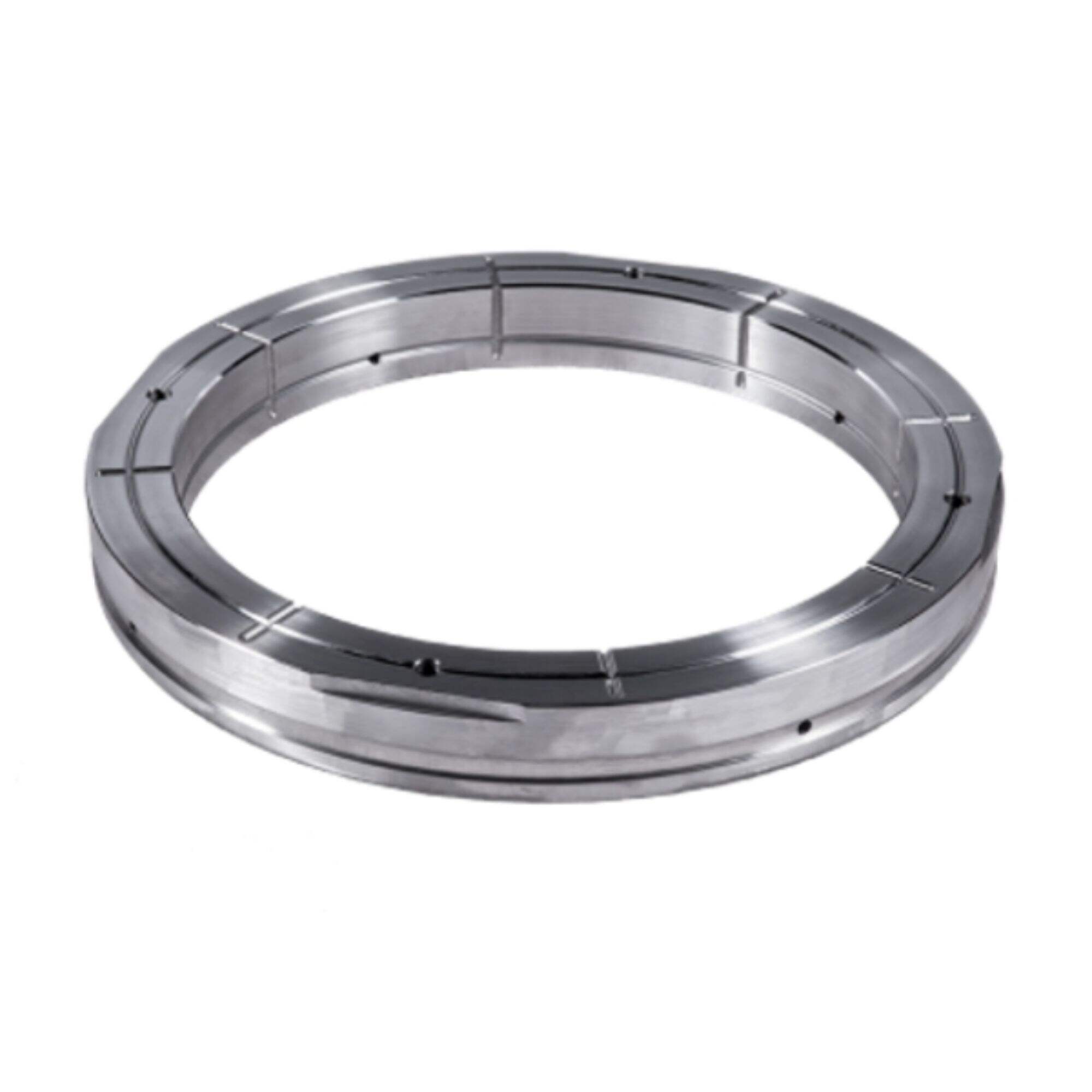

There are many specifics to consider when choosing linear rails and slides. Basically, these components needs to be matched with the weight and the size of a machine for smooth operation. Further, aluminum or steel materials (and plastic and ceramics etc) must be chosen contributing to the performance and need of application. Decision Making Aspects around these factors are crucial to ensure some sort of machine reliability.

So, to boil it down in a nutshell, linear rails and slides are not just plain parts or components used inside any manufacturing view but they indeed are one of the essential precursors that bring about precision and efficacies. This is how the factories can set a higher level with their production standards, as long they meticulously choose each of these key-components to send high-quality products up for sale.

Pingcheng is total process and lifecycle partner. The supply of the products is just the start of our partnership. Our customer service about ensuring your satisfaction. We've been providing machining services and building close partnerships with linear rails and slides for over 20 years. Based on decades of expertise and understanding of this industry, Pingcheng is dedicated to offering our customers honest prices. We examine the drawing with special software and presents the best solution the most reasonable costs when we receive offers.

Pingcheng's commitment for honest pricing is founded on years of experience in the industry and knowledge. After we receive the request for quote, we review the drawings and simulate linear rails and slides as soon as we can, and provide the best solution for your cost.

The supply chain and services of Pingcheng are designed to help clients achieve their goals in business. We concentrate on extending and increasing the potential and lifespan of your manufacturing. PingCheng is a linear rails and slides you've been searching for. We are a partner which delivers opportunities.

Pingcheng currently has more than 20 manufacturing facilities and 50 highly skilled technical employees. They linear rails and slides. Mitsutoyo's measuring instruments and CMM are periodically calibrated. The double-checking keeps our quality steady and accurate. The machining and assembly of all key parts are tracked and controlled.