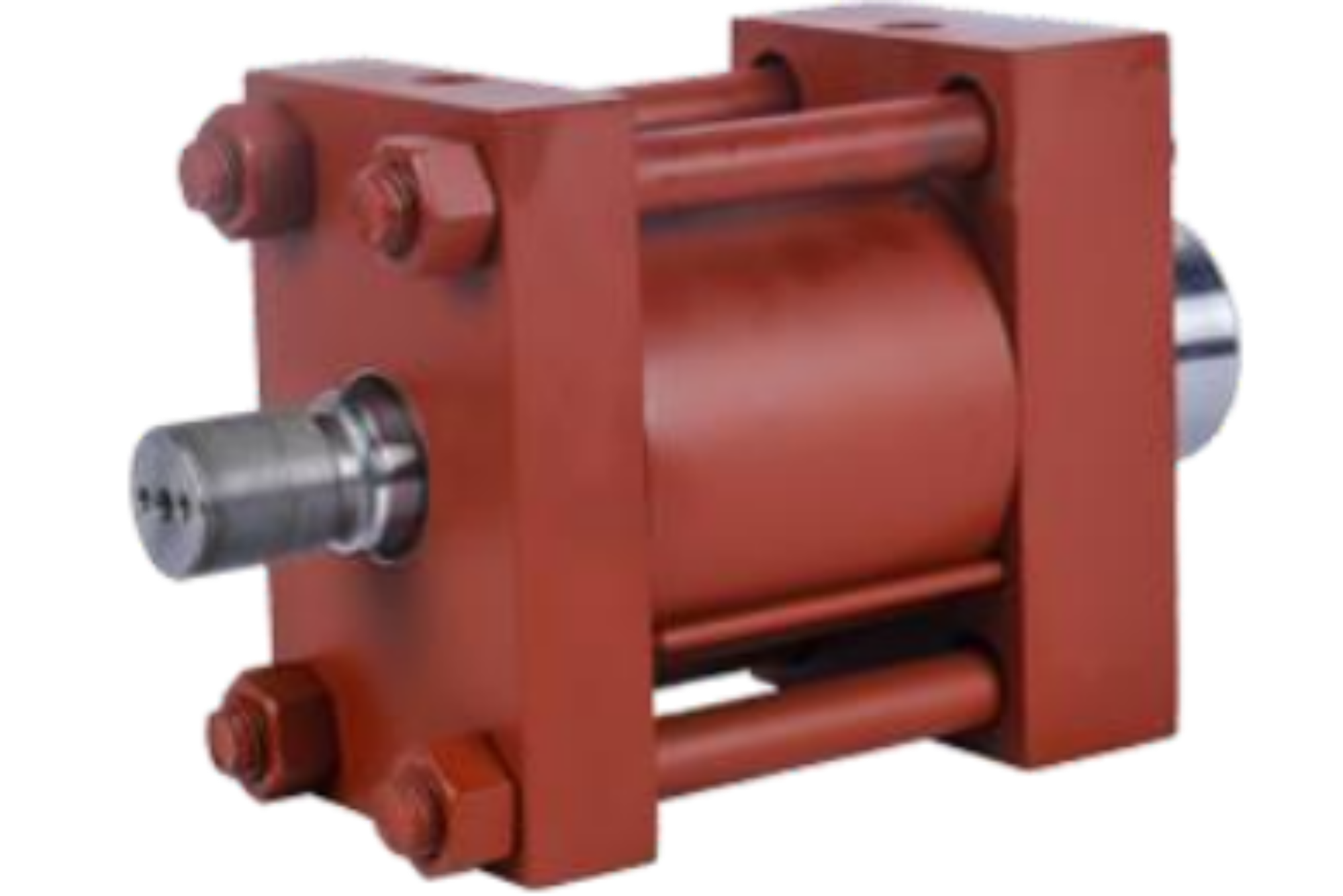

Injection Molding Machines, we all know are these machines where anything can be made fast and efficiently. These are suitable for producing lots of identical items (cars, buttons or parts to other machines) These machines are widely considered one of the favorite types to use by designers who want strong products that don't cost a fortune. This in turn makes it easier for businesses to offer their goods at a reasonable price.

Conclusion With Injection Molding Machines, the design can adjust to product-driven data. To earn more money online, they need to have lots of the same thoughts and wait for someone else (not them) select which one is best. This is fantastic because it lets them test multiple designs relatively quickly and cheaply. They can make several goods at a small amount of time by performing their method. But for that they can keep the cost low per item, which is a boon to both- the makers and customers.

Injection Molding Machines build repeatable sturdiness products for designers. The machine melts the plastic and puts it under pressure, which then forces the melted plastic into a mold that gives the product its final shape. This is important for consistency, to be sure that every product uniform and not weak. Taking all these products which are made in the same method, less chances of them getting broken or damaged. This is critical for the things that people touch every day.

it may sometimes be difficult to make products much tougher than those, but in case of such challenges Injection Molding Machines can help. For instance, these devices can do holes and thus the product is lighter in weight or easier to lift. They can also create very small objects such as miniature buttons or little machine pieces. It is this flexibility that makes many designers opt for these machines. These machinery aids in the production of products that are much more precise and accurate compared to those produced by human hands. This is good, as that helps the products to better interact with each other and perform stronger.

Injection Molding Machines are good for making things just right. Each product is created with such precision, that the look of every chocplate looks almost exactly like all others. The relevance of this for manufacturers is customers getting what they expect. Machines find malfunction of the mold or processThe important aspect is that in this way, problems with the mould (as well as machines) can be immediately found and resolved. The earlier a problem is identified, the easier it becomes for manufactures to address any problems and bring quality products. This ensures that the products being made are of good quality and safe for customers to use.

Pingcheng is committed to helping our customers reach their goals in business through our own supply chain and services solutions. We are focused on helping to extend and injection molding systems of your products. PingCheng is a dependable manufacturer that you're searching for. We are a trustworthy supplier of opportunities.

Pingcheng's injection molding systems is based on decades of industry experience and understanding. We review the drawing, model it using specialized software and then provide the most competitive price.

Pingcheng is a injection molding systems and lifecycle partners. The shipping of our products is only the beginning of our partnerships. Our customer services is about ensuring your satisfaction. Since more than 20 years ago, we have offered manufacturing services and have built a closed collaboration with well-known Japanese firms. Pingcheng's dedications to fair pricing is based upon our years of experiences and understanding of this sector. We analyze the drawing in an advanced software program and then provides the most efficient solution at the most reasonable cost once we have received the requests for quotation.

Pingcheng today has more than 20 manufacturing facilities and more than injection molding systems. They aim at providing high quality. Mitsutoyo's measuring devices and CMM are regularly calibrated. Double-checking helps keep the accuracy of our products and steady. Every single component can be traced and monitored during machining and assembly.