Have you ever wondered where your toys come from? It’s pretty fascinating! Injection Moulding: How Toys Are Made Picture it like baking a cake! We will melt plastic pellets rather than flour and sugar. From there, we pour the liquid plastic into a mould and create the toy. Pingcheng injection unit in injection moulding machine= use a machine that has what´s called an injection moulding unit, which allows us to melt the plastic and shape it in just the right way so we can make sure our toys turn out great.

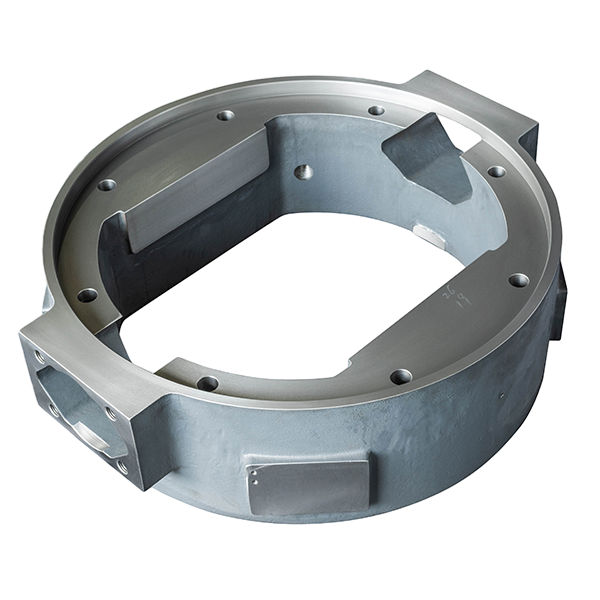

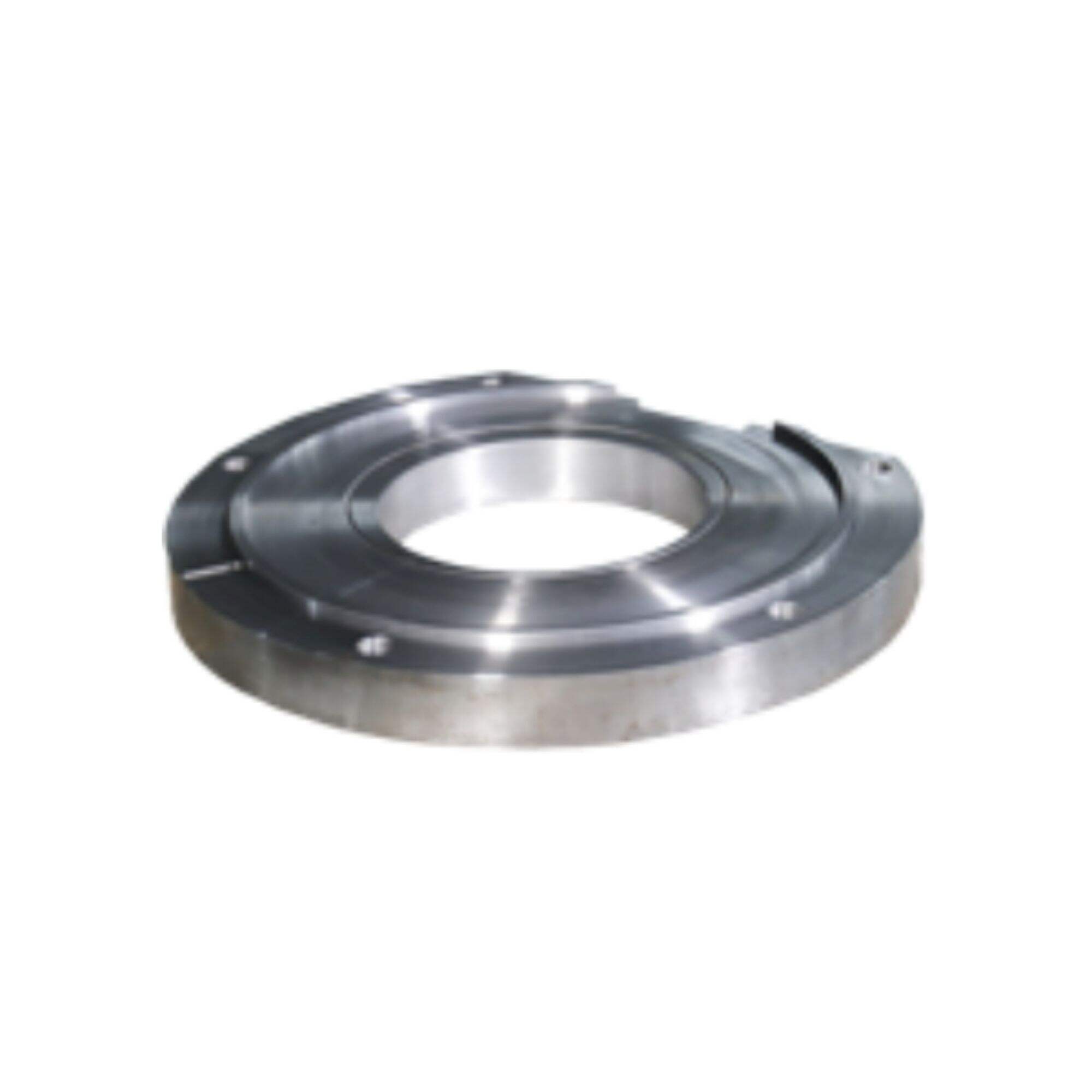

Injection Moulding Machine Review. Having the toy ready for your child or loved one, it carries with it a lot of responsibility and care. To produce good looking and performing toys, you must take great care of the injection moulding machine. That means cleaning the machine and ensuring it functions properly. The person using the machine has to understand how it works and hear/see in order to know if goes wrong. They need to verify for configuration issues. Pingcheng clamping unit in injection moulding machine would also be wise to have a back-up plan in place if anything goes wrong with the machine, or due to the plastic being an environmental pollutant. Thus, if there is any issue then it can be resolved immediately and the further toy making could not gets delayed much.

When using the injection moulding machine we need to consider many things. The first key thing is to identify the right temperature for your plastics. Either way, if it is not the right temperature, then that means they are too hot or cold and therefore their property melt can't be fixed with this plastic. We also have to take into account the speed that we inject on the plastic and because database software can change how we do toys mechanically. We must also think about volume pressure while injecting the plastic, but it is just as important to let us know for how long we will allow this same material that has been molded cool. It is not abstruse that all about takes practice and experience. Sort of like a recipe if you follow the steps correctly, it will result in a wonderful toy with Pingcheng fully automatic vertical injection moulding machine!

The smart use of this injection moulding machine can save lots of your time and money. One way to achieve this is by using technology which allows you control over each of the separate steps in the process. This can go a long way in helping the entire process to be smoother and less error-prone. Say for example we automate some of the repetitive work, this can also help to ensure everything is done in a consistent manner every time. The second consideration is: how can we save electricity during the use of the machine? It is basic like turn off machines, not in use, reduce running or waiting time this can save the power = less cost. This will make for a better toy and environment friendly if we think about it.

A lot of what we make into toys depends on the materials. Plastic pellets come in many varieties, and it is important to select the right one for the toy we wish to make. There are various types of plastics available in the market with different properties and using them appropriately can affect heavily over quality of your final product. The mold we use to produce the plastic. Also molds are much important. There are different molds, which make a variety of shapes and designs — one should consider what the machine can handle in terms of mixing these materials. This guarantees the toys are produced correctly and will meet desired quality criterion.

The supply chains and services of Pingcheng are Injection moulding unit achieves their business goals. We concentrates on extending and maximizing the values and life of your production. PingCheng is a dependable manufacturer that you're looking for. We are a reliable partners that can provide opportunities.

Our customer service focuses on your satisfactions. We have been offering an Injection moulding unit and developing a strong cooperation with industry well-known Japanese enterprises for over 20 years. Based on decades experience and comprehensions of this industry, Pingcheng is dedicated to offering our customers honest prices. We review the drawing using specialized software and provide most effective solutions at the most reasonable cost the moment we receives an inquiry for a quotes.

Pingcheng is now home to more than 20 manufacturing machines and more than 50 skilled technical staff. They Injection moulding unit. Then the products are inspected by Mitsutoyo measuring tools and CMM that are periodically calibrated. Double-checking ensures that the quality of our products precise and stable. Every single component can be traced and monitored during machining and assembly.

Pingcheng's Injection moulding unit is based on decades of industry experience and understanding. We review the drawing, model it using specialized software and then provide the most competitive price.