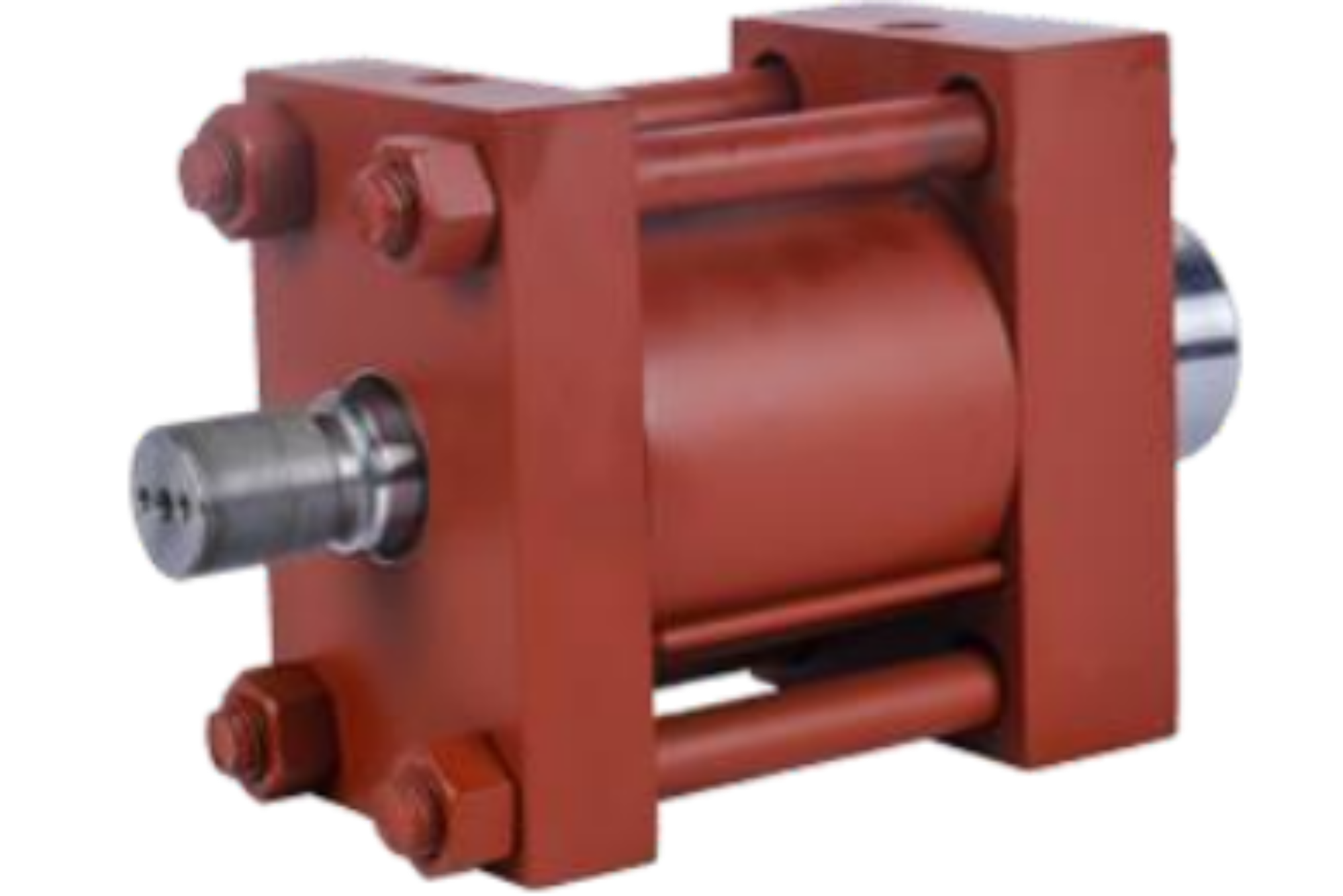

While it is a fact that injection molding machines are one of the most elementary tools used for manufacturing other plastic articles we use regularly in our lives. These kind of the machines are manufactured with a lot unique portion which assistance together in very smartly for producing best plastic goods. Clamping unit - which is commonly found in an injection molding machine and also classified as fundamentals. This post will explain what it does, and why you should be using one by now.

The function of a clamping unit in an injection molding machine is unique. This will keep the mold safe while it is injected with plastic. It is like the mold specified here has a shape of how it will be taken after by the plastic and should consistence at any rate. The clamping hold of mold is achieved by two plates of the clamping unit joining together. One plate is called STATIC platen which does not move The second one plate is becoming as PT) MOVABLE PLATEN that roads with the help of plasticizer unit in forward and reverse direction to shutlock it. Clamping force is the force that one half of a mold exerts in keeping both halves together while filling machine drives liquid plastic (plasticized material) into cavity and this pressure forces 2k molding compound to be set.

The Clamping unit in the Injection molding process This clamps the mold tightly during plastic injection line. This {is often|is usually} essential because it serves for making sure plastic vogue accuracy and distribution. The moulong section also has to retain the humid placed because that's how that region doing everything. If empty without the help of its associated clamping unit, discharged as mere lumps from a mold in semi-liquid state-plastic melts would lead only to massive waste. That can be horrifically expensive for a manufacturer trying to get their product through by the time they actually build it.

Performance of clamping unit - How good the plastic products have been produced is determined to a great extent based on how well the performance would be carried out in case of this part. Insufficient clamping can lead to quality issues for your plastic finish items. Data flash and warpage are two issues that often occur. Flash Flash is a thin layer, sometimes resembling rubber or as gauze-like fibers coming out from the parting line when releasing mold... Warpage: When a plastic part is removed from the mold, it may have areas that are distorted, or bent out of shape. To poor gripping conditions (the blank starts to move during the operation) or over-gripping, which results in deformation of any part shape.

Good clamping force = Good molding A good mold should be closed shut by a proper quantity of force, as any degree less will mean the CLAMP is not safe enough for all injection purposes. This is so that the mould assembly, while filling with plastic and bolted to plant floor; they do not move. The necessary amount of clamping force is determined by the size and shape form displayed in a mold ( if how big a piece) which ensures that only the right reaction forces are distribute over all molds, enabling every other part of your machine to move easily.

A high-performance clamping unit enables quick and smooth production that is essential for a manufacturer. It ensures that the mold is correctly closed up to a certain stage, i.e., at normal position required clamping force on this function otherwise only tight enough pressing unit applies so. It creates better formed areas quality A good clamping unit will greatly reduce flash and warpage problems. The lower the number of defects, quality goes up and less waste follows therefore it saves money for purchase.

Based on clamping unit in injection moulding machine and knowledge of the business, Pingcheng is dedicated to giving customers honest prices. We analyze the drawing, recreate the drawing using software that is specialized, and then offer the best price.

The supply chains and services of Pingcheng are clamping unit in injection moulding machine achieves their business goals. We concentrates on extending and maximizing the values and life of your production. PingCheng is a dependable manufacturer that you're looking for. We are a reliable partners that can provide opportunities.

Pingcheng has at clamping unit in injection moulding machine and 50 technical employees who have experiences. They are committed providing tops quality. Mitsutoyo's measuring instruments and CMM are calibrated regularly. The double-checking keeps quality reliable and accurate. Each keys part traceable and controlled during machining and assembly.

Pingcheng is a full-service and clamping unit in injection moulding machine. The shipping of our products is just the beginning of our partnership. Our customer service about ensuring your satisfactions. For more than 20 years we've provided manufacturing services and have built close collaboration with well-known Japanese companies. Pingcheng's adherence to truthful pricing is based our decades of experiences in the industry and understanding this sector. We analyze the drawing in special software and present the best solution at an affordable costs once we have received an inquiry for quote.