Did you ever wonder how you can get all those cool toys, gadgets or even furniture in your house? It’s pretty interesting! Injection molding is the process that produces these items. This is a very common method in factories as it can produce high volume of products accurately and quickly. Press injection molding: Press Injection Molding is a type of this manufacturing process.

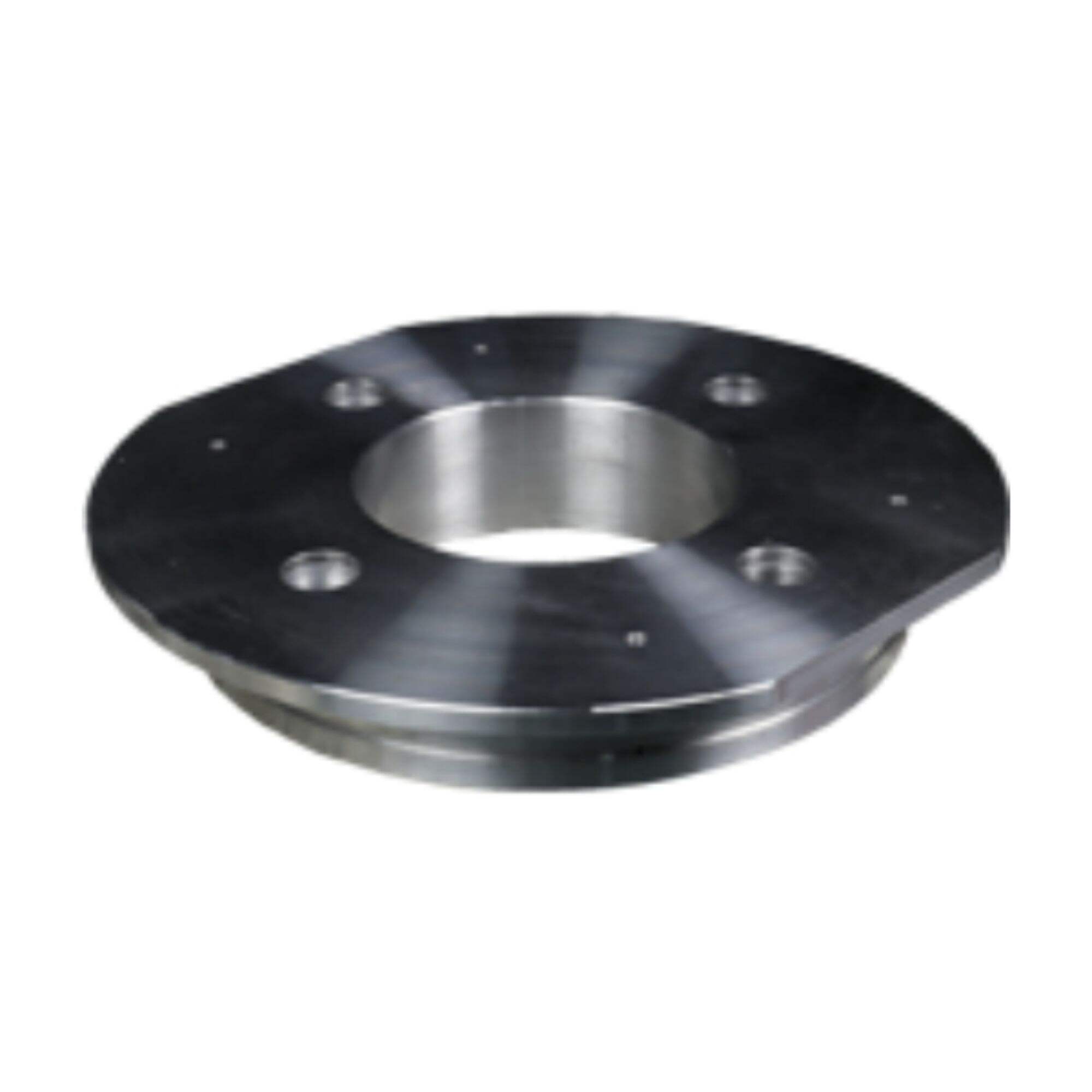

So, exactly what injection molding for press use is This process simply refers to when melted material such as plastic is forced into a mold under high pressure. The forces of this pressure help the substance to reach even untouched areas of the mold, ensuring detailed in individual parts. This is a great way of producing at large scale, and there are countless reasons why it works so well: some we can now discuss!

To begin with, speed. The process is really fast! Since the pressure is so high, molds fill rapidly meaning that parts can be made very quickly. That is critical because it allows companies to make a lot of products very quickly when lots of people want them. What if you could not buy your favorite toy because it takes a long time in establishing.

In the second, automatic press mold is extremely versatile that's why it can be meld in to numerous new destinations. Toys, car parts, things you use in the kitchen or even some medical equipment like important devices used in hospitals can be made using this process. This is ideal for businesses who are manufacturing various products/types of items, as you might have to include different facts/structural specifications into your BOMs/business process. The can swap between making toys and medical tools without issue!

A significant benefit of press injection molding is that it keeps companies running optimally and efficiently. A part in a molded form, the same mold can be used to make many parts so they dont need molds for each and every item.LinearLayoutmachined components This reduces time consumption and monitory expenses thereby the benefitting factor for businesses. The process can also be automated, allowing machines to do the work 24 hours a day without needing rest. This helps the companies produce more goods which is good for them when there are high demands.

Now, on to the making of really small parts. Injection molding is very good proces for making complex parts. The high pressure creates an opening for the melted material to pass through very thin gaps and small corners, enabling manufacturers to produce accurate designs. In medicine, for example when parts must be tallied precisely and moulded with great precision to work correctly. A surgical device, for example, where a small piece of the device has to be made just right so patients won't get hurt.

In general, the press injection molding significantly altered how products are manufactured. Today, it has evolved into a rapid and flexible approach for which firms can quickly create high-quality parts. The new procedure has enabled business to work better for even bigger portions while taking the strain off with constructing comprehensive parts they could not mak e before. This is a crucial technology for the manufacturing world, today and into the future.

With years in experience and a press injection molding, Pingcheng is dedicated to providing customers with honest price. When we receive a the request for quote, we review the drawings and simulates using special software right away, and then provide the most effective solution with a fair price.

Pingcheng is a press injection molding and lifecycle partners. The shipping of our products is only the beginning of our partnerships. Our customer services is about ensuring your satisfaction. Since more than 20 years ago, we have offered manufacturing services and have built a closed collaboration with well-known Japanese firms. Pingcheng's dedications to fair pricing is based upon our years of experiences and understanding of this sector. We analyze the drawing in an advanced software program and then provides the most efficient solution at the most reasonable cost once we have received the requests for quotation.

The supply chains and services of Pingcheng are press injection molding achieves their business goals. We concentrates on extending and maximizing the values and life of your production. PingCheng is a dependable manufacturer that you're looking for. We are a reliable partners that can provide opportunities.

Pingcheng now press injection molding and 50 technical staff with years of experience. They aim at providing high quality. They then inspect the products by Mitsutoyo measuring instruments and CMM that are periodically calibrated. Double-checking makes sure that the product's quality precise and steady. The machining and assembling of all important parts is monitored and traceable.