Flange type sounds like a long word for something that sometimes seems so little and not much to do but it has its work! Flanges are a method of connecting pipes, valves and other equipment to form a piping system. Selecting the proper flange type for your application is important in maintaining a well-running system. This informative read will provide a deeper look at the various types of flanges, their advancements and where they are used according to industry needs.

Flanges are importantly shaped parts and come in many types each serving a different purpose. The pressure and temperature of the system for which it will be used are by far some basic consideration to make in selecting a flange type. This influences the material of the flange, ranging from robust steel and stainless steel to malleable plastic and rubber. The type of pipe and its size that will be connected with the flange is another feature to consider as it determines if you have a proper match-up in your piping system.

So, types of the flange are available to various pipes Such as weld neck flanges and slip on plates. So, in this post let us dive into few of such:

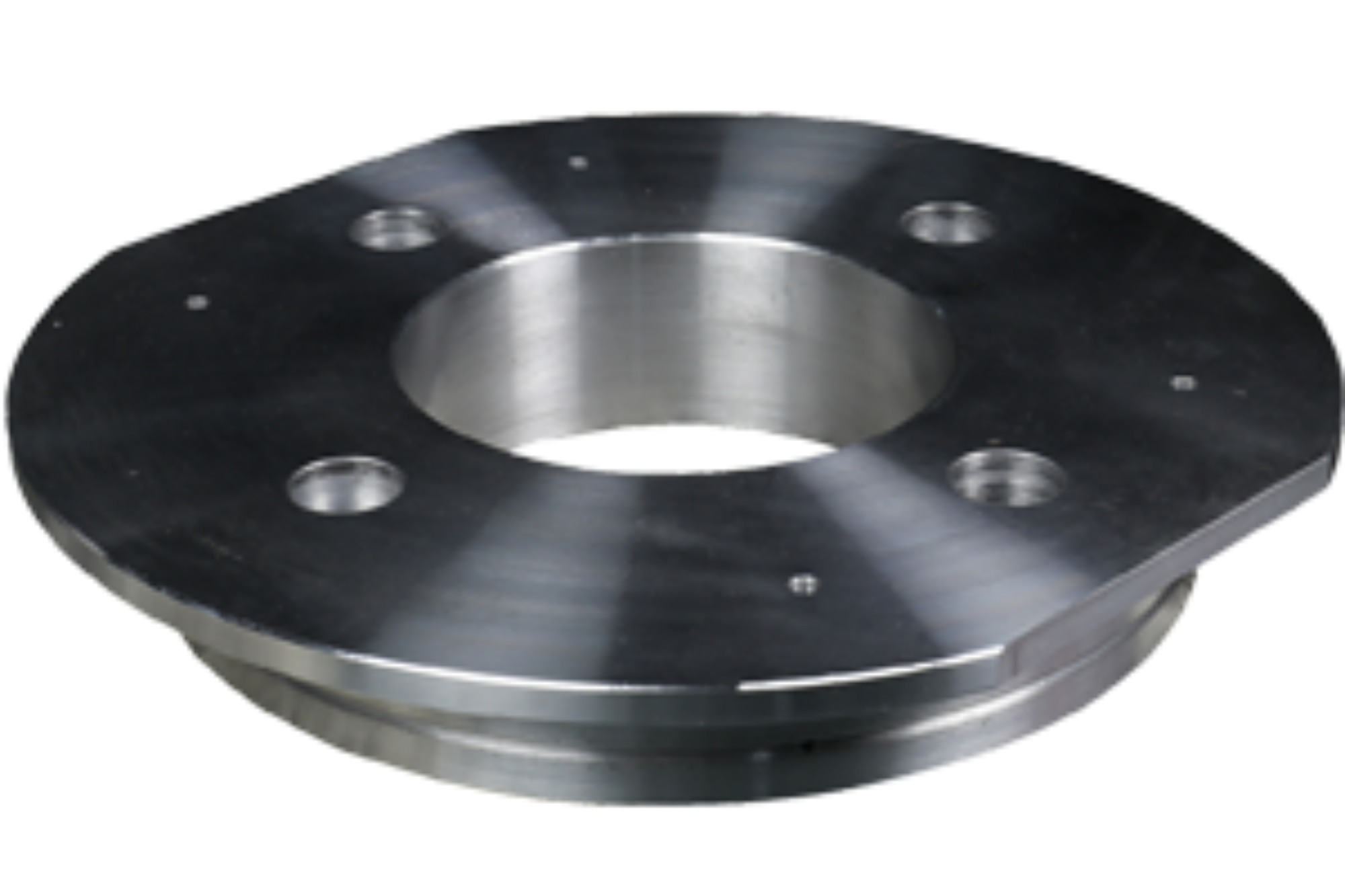

Weld Neck Flanges: As the name implies, Weld neck flange is a welding circular plates which engraved around the pipe end. They come with a longer neck that gives added support to the pipe and helps in preventing bending or distortion. You should know that the weld neck flanges must be welded by experienced workers.

Slip On Flanges: These are known for their simple installation and are suitable for low-pressure; non-critical applications. Even though they are easy to use, these are not as reliable with the weld neck flanges since it is prone to changing its conservation when exposed under pressure.

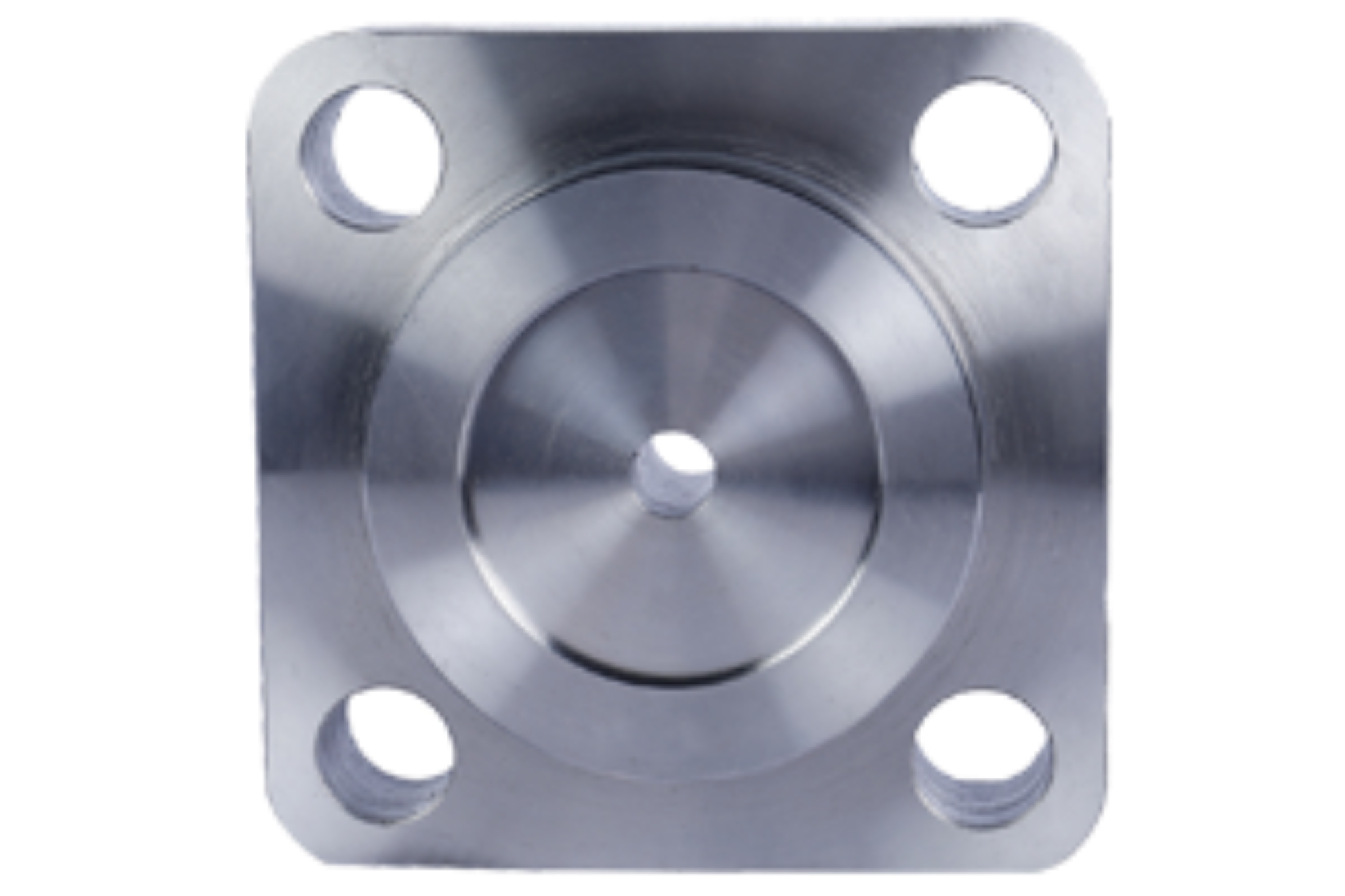

Blind Flanges - Blind flange is used to blank off the ends of piping, valves and pressure vessel opening. However, they do not work on connecting pipes or equipment.

Socket Weld Flanges: Primarily used for small size pipes and high pressure application & socket weld is considered as an integral piping component with its ease of installation and supported advantages. Like weld neck flanges, they also need professional welding skills for a perfect solvent operation.

Flanges are instrumental in connecting pipes to equipment and flange makes rest maintenance or replacements easier as there might be easy dismantling. With that said, some very notable benefits of using flanges in your piping system include:

Quickly Installed: Flanges are installer-friendly and can be installed with little to no welding necessary.

Durability: Flanges are made from tough materials that do not easily succumb to corrosion and hence can withstand high levels of pressure & heat

Versatility: Flanges come in all different types of shapes and sizes which means they can be used to fit a vast array of pipe configurations, equipment setups etc.

Easy for Maintenance: Flanges make it easier to reach the pipeworks enabling quick and simple maintenance or repair tasks.

Now that we have identified the advantages and disadvantages of some common flange types, let's move on to how these styles are typically used within industrial scenarios:

Weld Neck Flanges:They are in use at higher-pressure and corrosive service levels as well, which makes it useful for oil fields etc.

Slip On Flanges: They are widely used in industries such as water treatment, food processing, and pharmaceuticals where it is mainly associated with lower pressure (or low prices).

Blind Flanges - critical for pipe end closure required when testing with hydro-testing, nitrogen purging or leak test.

Socket Weld Flanges: Common in systems such as steam piping, hydraulic setups, and compressed air versions but not limited to exist only on smaller pipe sizes.

Therefore, you can not take "Flange type" lightly but for your commercial business which gives extreme significance to decide on accurate flanges in order that it suits your piping system. By weighing out the system pressure, temperature as well as pipe size and material compatibility you can decide what is best for the continued health of your water filtration system. Also, using flanges confer several advantages like easier installation process Once connected no issues with leakages Fits for the extended period and easy maintenance fossilized. With the above understanding about flange types and uses, you will be able to find appropriate use-cases thereby efficiently choosing at need your required industrial requirements.

Pingcheng now flange type and 50 highly skilled technical employees. They strives to provides high quality. Then, the products is inspected by Mitsutoyo measuring instruments and CMM that periodically calibrated. The double-checking keeps quality reliable and accurate. The machining and assembly of important parts controlled and traceable.

The supply chain and services of Pingcheng is designed to assist customers reach their business goals. We focus on extending and flange type. PingCheng is the reliable manufacturer you're looking for. We are a partner which delivers options.

Based on decades of experience and flange type, Pingcheng is dedicated to providing its customers with a fair price. We examine the drawing, model it with specialized software and then give you the most affordable price.

Pingcheng is a full-service and flange type. The shipping of our products is just the beginning of our partnership. Our customer service about ensuring your satisfactions. For more than 20 years we've provided manufacturing services and have built close collaboration with well-known Japanese companies. Pingcheng's adherence to truthful pricing is based our decades of experiences in the industry and understanding this sector. We analyze the drawing in special software and present the best solution at an affordable costs once we have received an inquiry for quote.