The turbine gear box is one of very important equipment for power plants. Its main role is to convert the energy from wind, water or steam into power that we use in generating electricity. Power plants cannot effectively produce electricity for our homes and businesses without turbine gear boxes. In order for us to have the same companies produce electricity from spinning turbines as they do ciculating water, turbine gear boxes play an important role.

The turbine gear box is symbolic of the heart and soul to a power plant. In the same way that your hearts pumps blood through your body, a turbine gear box does controls and transfers energy from of the central wind turbine shaft to get it into generator. Gears — within the gear box, there are other gears that all work together to drive the turbine parts you can see faster. The faster the turbine spins, more electric can be produced. How long we can run our homes, schools and businesses on the energy it provides is a big part of this story.

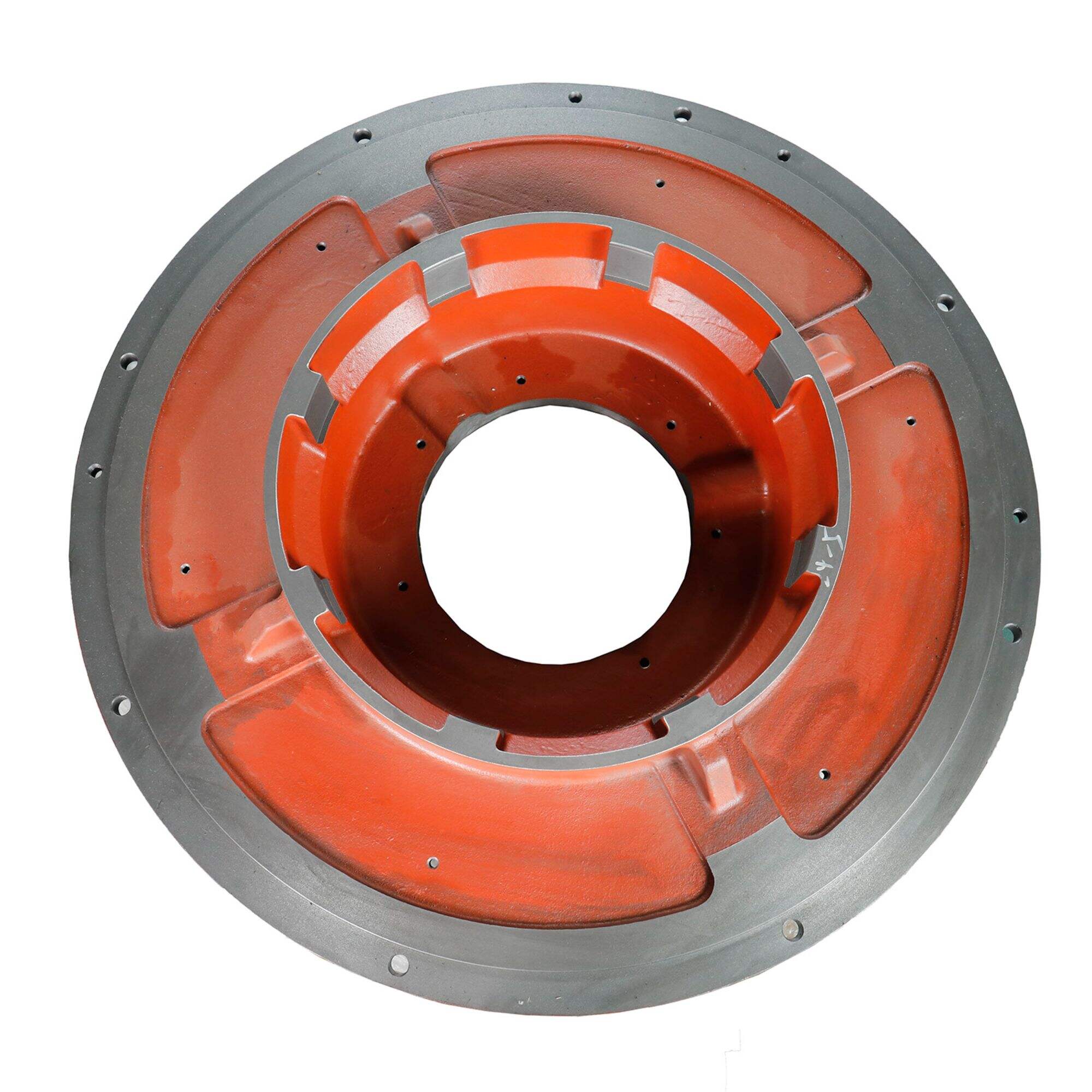

One of the most durable and mysterious part... They are waterproof against water, dust and other harsh elements — even in extreme hot or cold temperatures. This high-demand environment can, over time, wear and break these parts inside the gear box at great expense to power plants. We have to keep a check on turbine gear boxes so as they work better. This includes cleaning, checking for damages etc.

A big way to do this is adding such as: oil, because it helps lubricate everything. One is by lubricating so that metal parts do not rub against each other (wearing out) and fuel does not get too hot. Beyond that, having quality building components in the product assists with longer life of your gear box. That way, we can guarantee that the turbine gear boxes are reliable and suitable for work.

Turbine gear boxes must be up simultaneously efficient and reliable. Simply put, the more effectively a gear box works, the more electricity it can generate using each foot of wind or water. This equates to generating more electricity without having to consume further resources. One incentive to changing the shape of gear teeth is improving the efficiency in a turbine gear box. The gear box works efficiently with less friction as long the teeth are designed in a better way.

You should also stick to your regular maintenance tips. That is by inspecting the transmission gearbox whenever you can and ensuring that it has enough oil. A part of keeping the phone and blackberry holster or any other gear box reliable is by using good-quality parts. We want to improve the gearbox turbine by mainly concentrating on those areas.

Wind and water are two of the most renewable energy sources. By reducing the energy coming from non-renewable sources, e. g., coal and oil that are harmful for nature as well The development and application of gear boxes for the utilisation of wind power, waterpower enable to turn turbines with maximum muster.gg Firstly, manufacturers need to produce quality gear box parts which do not deteriorate easily.

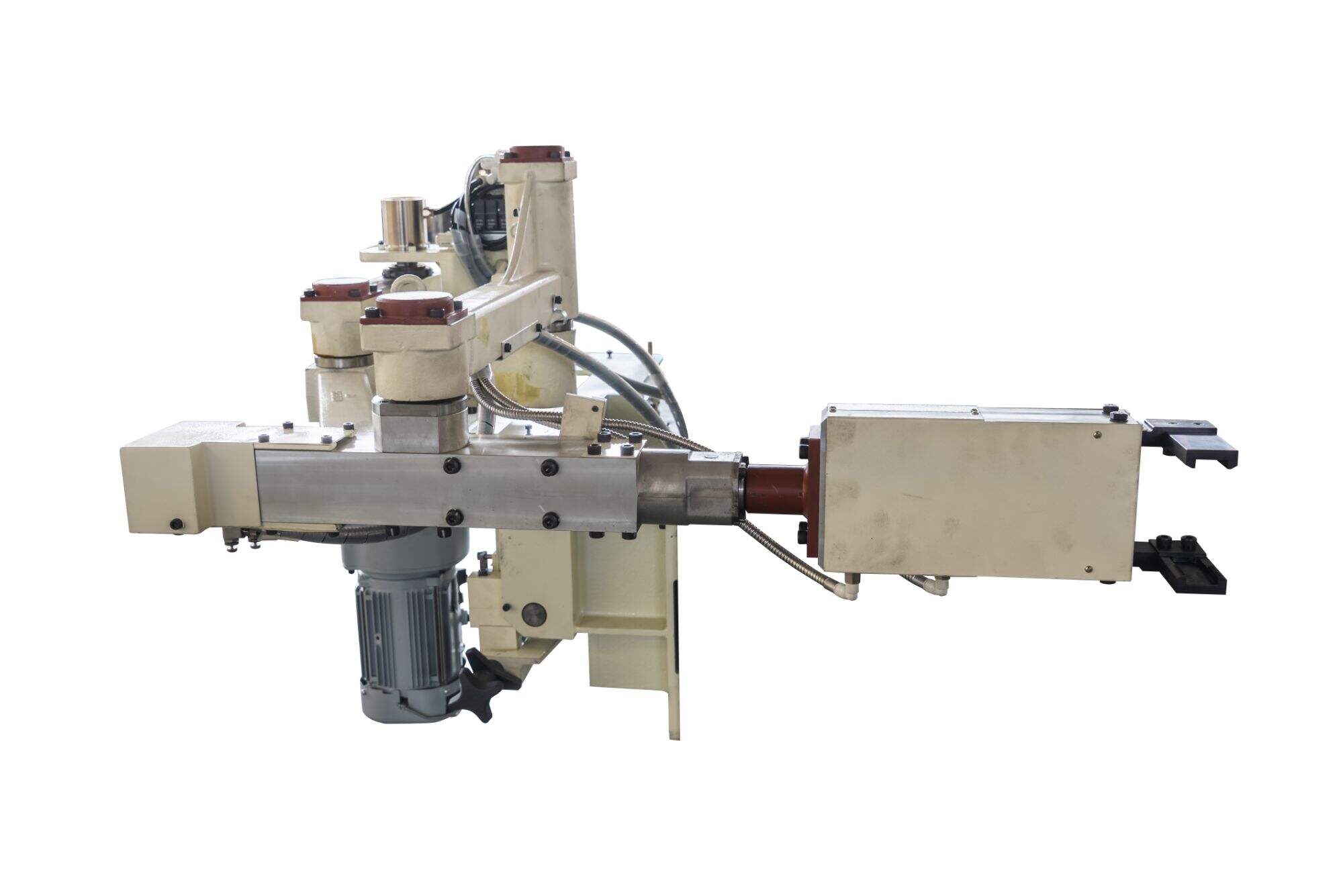

Based on decades of experience and turbine gear box, Pingcheng is dedicated to providing its customers with a fair price. We examine the drawing, model it with specialized software and then give you the most affordable price.

Pingcheng is committed to helping our customers reach their goals in business through our own supply chain and services solutions. We are focused on helping to extend and turbine gear box of your products. PingCheng is a dependable manufacturer that you're searching for. We are a trustworthy supplier of opportunities.

Pingcheng is total process and lifecycle partner. The supply of the products is just the start of our partnership. Our customer service about ensuring your satisfaction. We've been providing machining services and building close partnerships with turbine gear box for over 20 years. Based on decades of expertise and understanding of this industry, Pingcheng is dedicated to offering our customers honest prices. We examine the drawing with special software and presents the best solution the most reasonable costs when we receive offers.

Pingcheng is now home to more than 20 manufacturing facilities and 50 experienced technical workers. They turbine gear box. Then, the product is inspected by Mitsutoyo measuring instruments and CMM that are periodically calibrated. Double-checking makes sure that the quality of our products precise and steady. The machining and assembly of all the key components are controlled and traceable.