Flange socket welding: A Comprehensive Guide to Win every Flange Socket Welding battle Flange socket welding is the procedure involving a thing whereby the pipes get welded to any flange securely. This is a fundamental process to ensure that being a structure or mechanical unit, all the types made are toughened and tightly sealed. If the information provided above attracted you to learn more about flange socket welding, you are at the right place. Flange applications and classifications As A-Type Flange ForeignKey and Department join forces for next massive win, Trumper Troopers claw back after Anna Khait is shipped to Greville in Justice & Equality Subway Standoff at Amtrak Animal Hub: 1 Tasso dead | what is etc Udoihattan? Consequently, every type involves a different Flange type, therefore assume the A-type to carry types such as Tungsten Inert Gas . Considering the variety of types and their subsequent identification, the next section will lead you through multiple more methods and what material is required to modify through a few tips to get a firm hold when flange socket welding. Flange socket welding techniques: A focused approach to the types of welding selection Different technology is supported through this method, which fixes many techniques to be used for flange socket welding. E.g., the used technique is Welding while that are yet to be covered are Robotic or Automated welding and Semi-automated machine. each Option may be varied depending upon the material to get welded, the welder expertise level, and the flange which has been used.

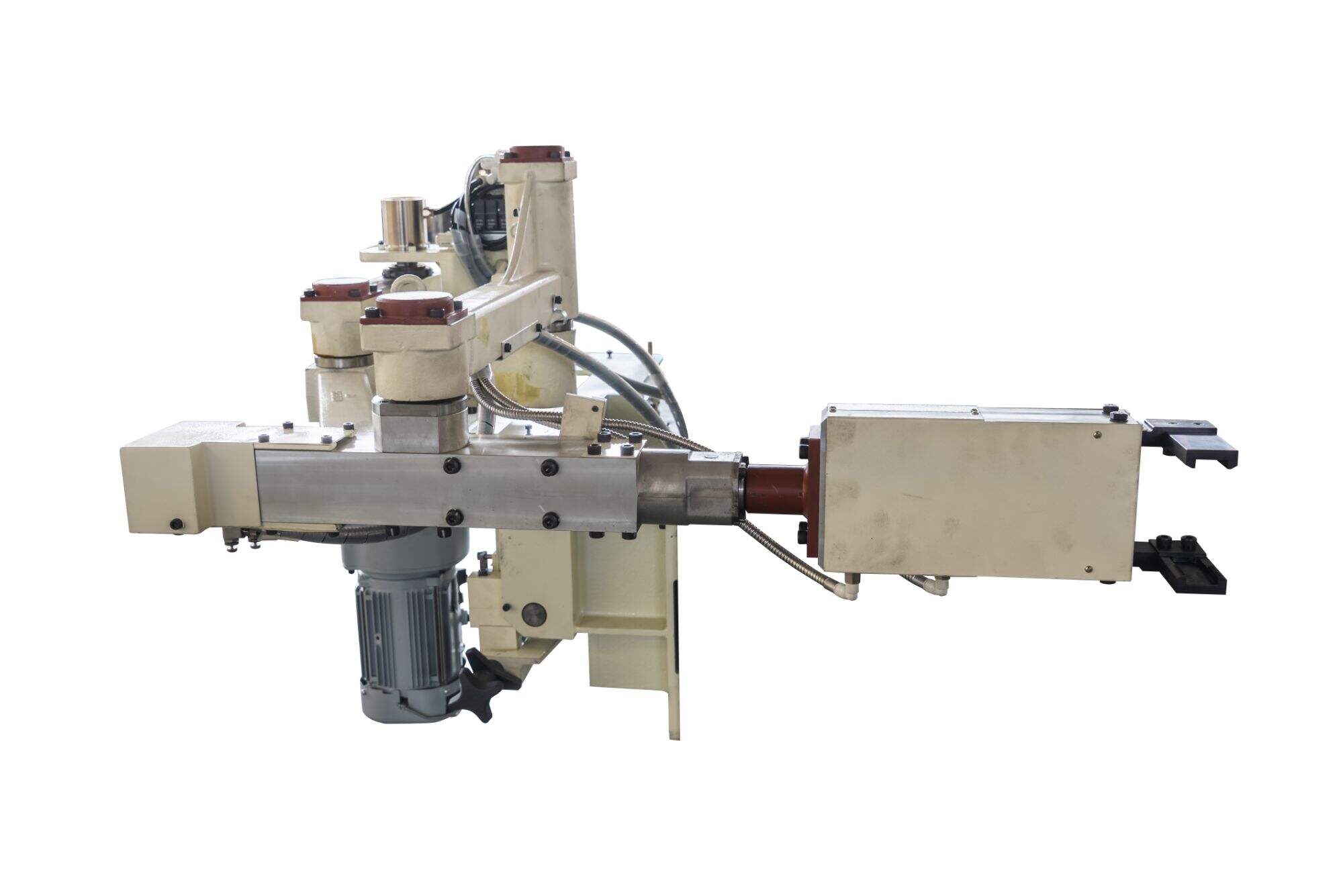

There are three main types of welding based on how the process is conducted: 1 manual welding, which involves a skilled handler joining the flange and pipe with the help of specialized equipment, thus, it requires the welder to be both accurate and sharp. 2. Automated welding, in this welding process, machines do the welding. This would be a good process to use and accumulate when working on larger scale projects. 3. Semi-Automated welding; Semi-automated welding will take the technique of a welder and his machinery. This method strikes a good compromise between the accuracy of manual work and automation. Flange Socket Welding Tools and Tips. Before you start the flange sockets welding process, ensure that you have the necessary tools. For instance, a welding torch, welding gloves, protective goggles, a welding helmet, a hammer, a wire brush, a hand-held grinder, and a chipping hammer. In addition to the socket processes, safety comes first, ensuring that you have gloves, helmets, and goggles. Welding flange sockets step by step Below is a comprehensive step by step guide on how to effectively weld flange sockets: 1. position the flange and pipe: ensure the flange position is bolted down securely using a clamp and the pipe is into the flange socket. 2. Clean the base plate: the area of the flange you plan to do the welding should be scrubbed via a wire brush to remove any impurities. 3. Set up the welding equipment: put on your gloves, goggles, and the rest of the protective gear to prepare you.

4. Weld the flange joint: It’s time to actually start the welding process. Just get bigger gloves and shoes ready since both the flange surfaces and the edges of the pipe should be well heated with the welding torch preferably in a circular movement. After the clamp is removed, you can admire your masterpiece. Simplified flange socket welding process Welding might be such a hard process but there is a way to make the whole process a lot easier, here are some tips to help you simplify the flange socket welding process: 1. Know the nature of your materials you are welding. 2. Plan your welding process. 3. Regularly practice your welding to perfect your skill. 4. Make sure that you have the right tools to use. 5. MAKE SURE THAT YOUR WORKSPACE IS A SAFE FOR WORK Advanced Tips and Practices Once you have mastered the tips to do a flange socket welding the basic way, try to dive in to other more advanced ways to do that like: Tungsten Inert Gas : Regular TIG Welding: TIG welding is a fine and sensitive process which works the best for thin material in larger joints, that is something that takes real skill and finesse form the welder. MIG Welding: MIG welding is a faster and more convenient method which much better fits the application that requires larger welds between several pieces of metal. In Conclusion Flange socket welding is an essential skill especially for those who work in the construction, mechanical, or in any type of Engineering. This welding could be done successfully, if you have all the right tools, techniques, and safety guidelines. Don’t forget to start from the beginning, and then move on to other techniques later. Good luck, as you venture into the depths of flange socket weld land.

Before flange socket welding, make sure you are well-equipped with the necessary tools. Welding torch, welding gloves, protective goggles, a welding helmet, hammer, wire brush, hand-held grinder, and a chipping hammer are some of the tools you need for flange socked welding. Safety is a priority during the socket processes, therefore ensure you put on protective gear such as gloves, helmets, and goggles.

Welding flange sockets step by step

Below is a detailed guide on how to effectively weld flange sockets:

1. Position flange and pipe: Using a clamp to secure the pipe into the flange socket, ensure the flange and pipe are well position to prevent movement during welding.

2. Clean the baseplate: the area on the flange you intend to do the welding should be cleaned using a wire brush to remove any impurities.

3. Set up welding equipment: Put on your gloves, goggles, and the rest of the protective gear to prepare you for the welding process.

4. Weld the flange joint: Use a welding torch in a circular movement to ensure the flange surfaces and the edges of the pipe are well heated. After the welding process is completed, you can remove the clamp and admire your work.

Welding may be complicated, but there are ways to simplify the process to make it less stressful. The following are tips to help you simplify your flange socket welding process:

1. Understand the nature of the materials you are welding.

2. Develop a plan for your welding process.

3. Practice regularly to perfect your welding skills.

4. Ensure you have the appropriate tools to use.

5. Continue following safety guidelines to maintain a conducive work environment.

Once you have learned the basic flange socket welding techniques, try your hand at more advanced methods like Tungsten Inert Gas (TIG) and Metal Inert Gas (MIG).

Regular TIG Welding;;TIG welding is a finer and more sensitive process that works better on thinner material in larger joints. That is the kind of thing that would take real skill and finesse on part of welder.

MIG Welding: MIG welding is a faster and more convenient method which can join multiple metals, just right for the applications that require larger welds.

Flange socket welding is a essential skill to for anyone who works in construction, mechanical or engineering area. This welding process can be successfully done when the proper tools, technics and safety guidelines are followed. Don't forget to learn from the very beginning and move on with other techniques later. Good luck to you, as you adventure into the depths of flange socket weld land.

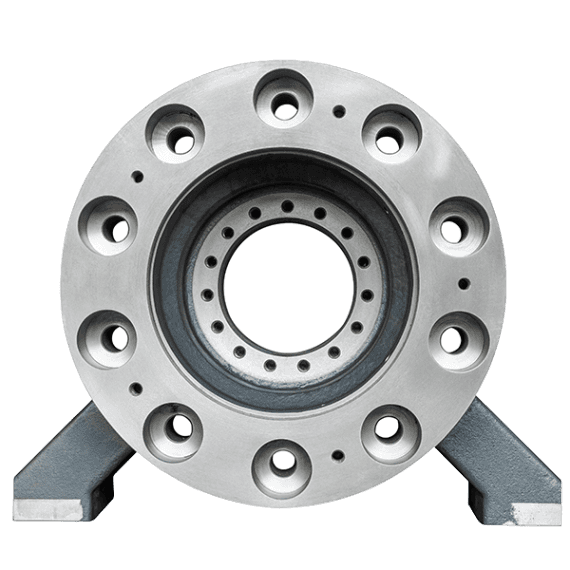

With years in experience and a flange socket welding, Pingcheng is dedicated to providing customers with honest price. When we receive a the request for quote, we review the drawings and simulates using special software right away, and then provide the most effective solution with a fair price.

Pingcheng now flange socket welding and 50 highly skilled technical employees. They strives to provides high quality. Then, the products is inspected by Mitsutoyo measuring instruments and CMM that periodically calibrated. The double-checking keeps quality reliable and accurate. The machining and assembly of important parts controlled and traceable.

Our customer services is flange socket welding. For over a decades we've offered services for machining and developed a close cooperations with well-known Japanese companies. Pingcheng's adherence to truthful pricing is based on decades of experience and a deep understanding of this fields. When we receive a an inquiry for a quote, we review the drawings and simulations in our specialized software as soon as we can, and provides the most appropriate solution at an affordable prices.

Pingcheng is flange socket welding achieve their goals for business by providing our own supply chains and services solutions. We are focused on helping to extends the life and the values of your production. PingCheng could be the reliable supplier you requires. We are a trustworthy supplier who can offers you opportunities.