The injection cylinder mechanism is interesting. It heats the material until it is at extreme temperatures, causing them to melt. In the second step, that molten material is driven through a small opening at the end of the cylinder-with this nozzle-and into your work space. This is the most crucial part as it will be handling and injecting your melted material into the mold. After entering the model, contacts and cools down. And once the candy fully cool down, it becomes a mold. This helps in getting the products produced correctly when it comes to shape and volume.

Injection cylinders make such a perfect match of items against different shapes and sizes. This includes items such as plastic toys, phone cases, metal car parts or even medical devices for which every device is made by its own injection cylinder. Thanks to the injection cylinder, these come together quickly and accurately.

For plastics manufacturing, the injection cylinder heats up small plastic pieces (pellets) until they melt into a liquid form. It will be a mold fabricated in metal to create the part as desired, where melted plastic is injected. Once the plastic cools and hardens, you release the mold - and your finished product The entire process is fast, so a lot of products can be made in just few seconds.

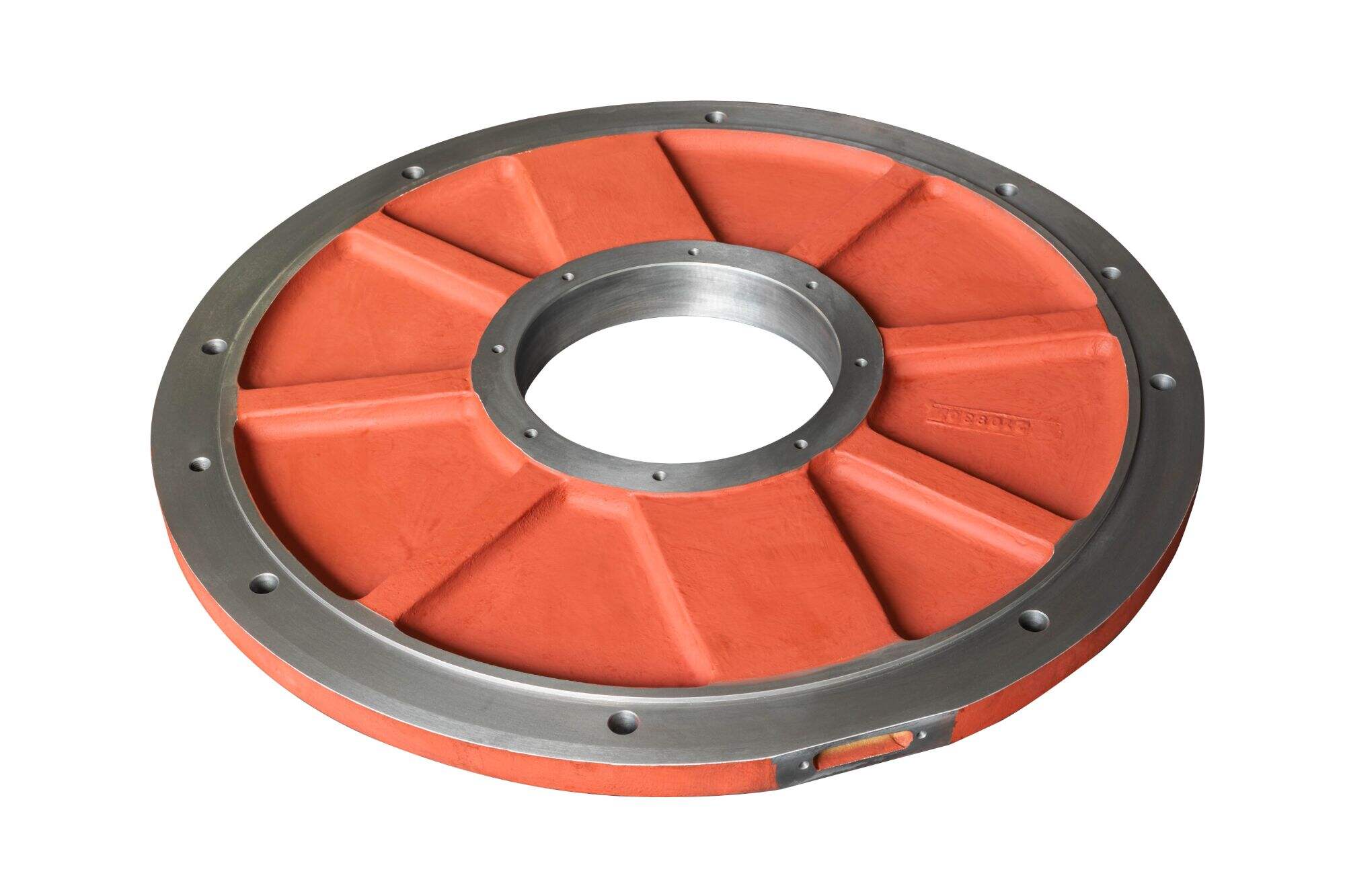

In the case of metal products, this function is performed by a nozzle as well; however, in the large-scale equipment used to make such components (known generally as an injection cylinder). It actually melts the metalliquid. The metal is melted, and then it's pushed into the mold to form a specific shape. Once this metal cools and solidified the mold is removed, unveiling a finished product. It is an extremely efficient method that allows for a high precision of metal products.

A major improvement in the field of injection cylinder technology is these electric systems dose now feature computer-controlled dispensers. By this, it means that these sophisticated systems can keep an eye on critical indicators such as the temperature of materials being injected, specific pressure they are maintained with at various sections in inject and how much material flow has occurred during injection. Through thorough inspection of these factors, the computer systems are able to make sure that the injection is precise as well as reliable

Another interesting development are the multi-cavity injection molds - special moulds designed for this type of work. They allow manufacturers to make numerous (many) copies of a product all at once. This results in many more products being able to be produced at a much smaller period of time which saves money and helps the production process.

That said, the injection cylinders are really among one of them and require thoroughly being taken care so as to keep the manufacturing processes safe and efficient. If workers are not trained properly and an accidental situation occurs, someone is likely to be injured from the high-pressure liquid coming out of any number of injection cylinders.

Pingcheng now injection cylinder and 50 technical staff with years of experience. They aim at providing high quality. They then inspect the products by Mitsutoyo measuring instruments and CMM that are periodically calibrated. Double-checking makes sure that the product's quality precise and steady. The machining and assembling of all important parts is monitored and traceable.

With decades of experience and comprehension of this industry, Pingcheng is dedicated to providing its customers with a fair price. Once we have received a the request for quote, we injection cylinder in our specialized software right away, and then provide the best solution for your cost.

Pingcheng is committed to helping customers achieves their business goals through our injection cylinder and service solutions. We concentrates on helping you extend the life and values of your production. PingCheng is the dependable manufacturers you're looking for. We are a company that delivers options.

Pingcheng is total process and lifecycle partner. The supply of the products is just the start of our partnership. Our customer service about ensuring your satisfaction. We've been providing machining services and building close partnerships with injection cylinder for over 20 years. Based on decades of expertise and understanding of this industry, Pingcheng is dedicated to offering our customers honest prices. We examine the drawing with special software and presents the best solution the most reasonable costs when we receive offers.