2500 Ton Molding Injection Machine Amazing!

The 2500 ton injection molding machine is a fascinating piece of equipment in the plastic manufacturing world. This giant of a machine helps to manufacture different plastic products using its huge size and capacity, consequently inspiring the industry.

The Latest Marvel in Engineering

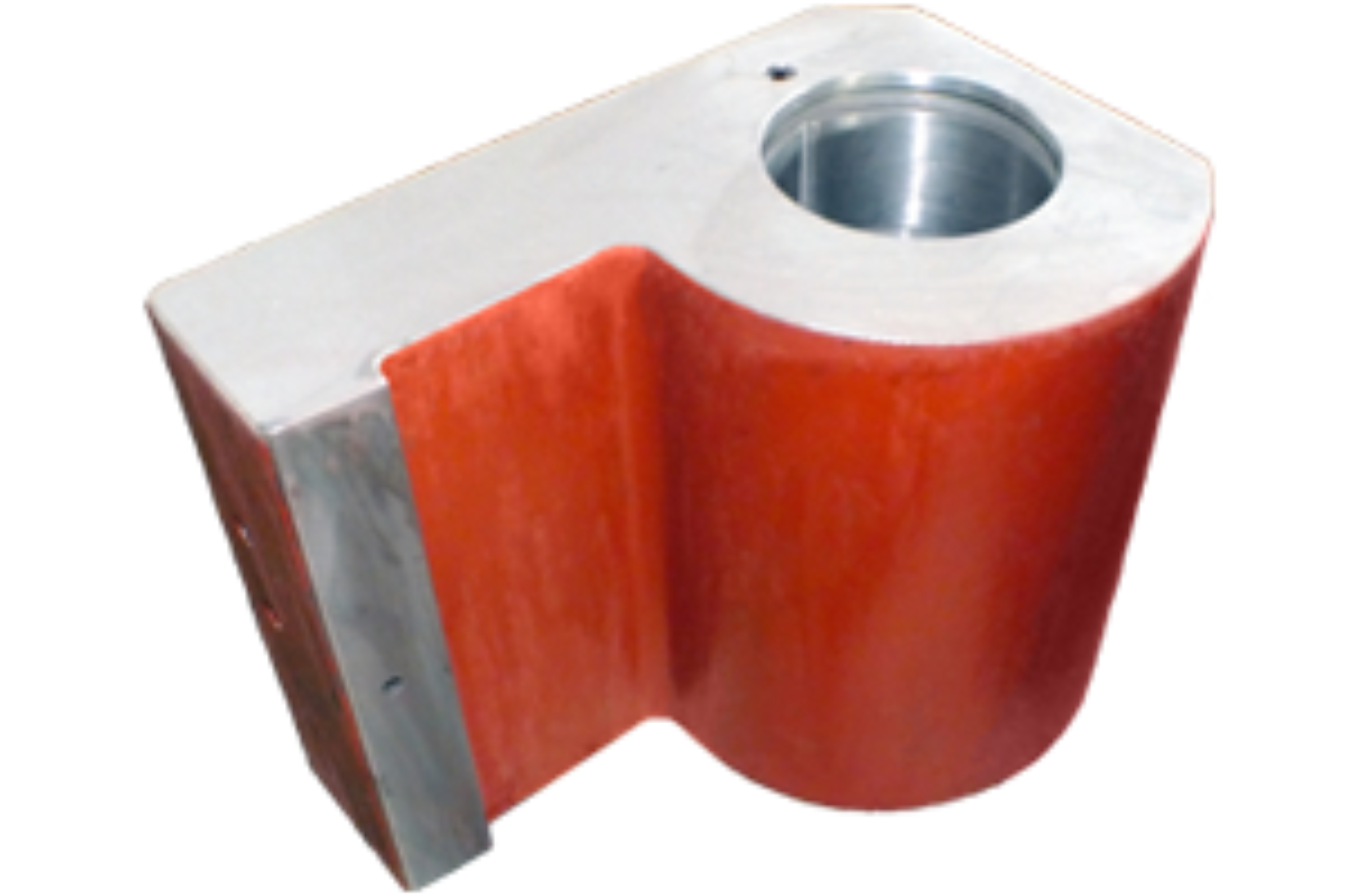

It is a monolithic device that will print out multiple things at once, taking raw plastic and turning it into whatever new objects you need with almost magical rapidity. This 2500-ton injection molding machine is the most visible, looking like some kind of giant box out from whence plastic goes in on one side and emerges as something else entirely.

Setting the Gold Standard

It is a standard which has set benchmarks in large plastic article manufacturing at the heart of the plastics industry, and this 2500-ton machine made it all possible. This machine provides a practical application from essentials like car parts to the daily items you use, including vessels and toys... even if it only makes molds of them for different production materials.

The full charm of the 2500-ton monster is in its capacity to dance high numbers of molds at anyone time, allowing factories dump endless copies out sheet after sheet. This is where pros make pots, pans cakes - and all mass-manufacturing industries operate, for the machine can easily shape multiple forms with ease.

Likewise, when it is required of them to mould huge plastic parts then 2500 ton machine fulfils the necessity. This is a foundational machine that can pump out oversize parts with ease, such as car bumpers and airplane wings. There is nothing else in the industry which transitions as seamlessly into this level of workflow.

Changing the Rules of the Game

Last but not least, this 2500-ton machine has been labeled as a game-changer in the plastics sector because it makes preparing and producing moulds faster & simpler than ever. This machine can take over a process that is time-consuming and slow where each item needs to be made separately by hand, which makes production more workflow-friendly for factories.

There are quite a few advantages of using the 2500 ton Injection Molding Machine. In extent to the mass production of multiple products at once, it plays a vital role in yielding large size components that caters various industrial applications. In addition, it can form different types of shapes which makes the tool high on need for fabricating a variety of plastic products.

Basically, the 2500-ton injection molding machine is a representation of innovation and productivity in plastic manufacturing industry. This machine revolutionizes the business landscape, delivering unprecedented advantages to manufacturers all over by driving high-volume moldings, creating big parts and allowing a wide range of shapes.

Pingcheng currently has more than 20 manufacturing facilities and 50 highly skilled technical employees. They 2500 ton injection molding machine. Mitsutoyo's measuring instruments and CMM are periodically calibrated. The double-checking keeps our quality steady and accurate. The machining and assembly of all key parts are tracked and controlled.

With years in experience and a 2500 ton injection molding machine, Pingcheng is dedicated to providing customers with honest price. When we receive a the request for quote, we review the drawings and simulates using special software right away, and then provide the most effective solution with a fair price.

The supply chain and services of Pingcheng are designed to aids clients achieve their goals in business. We 2500 ton injection molding machine as well as maximizing the values and life of your manufacturing. PingCheng is a dependable manufacturer you are looking for. We are a suppliers that offers a variety of options.

Our customer services focuses your satisfaction. We've been providing the machining services and 2500 ton injection molding machine with industry-renowned Japanese businesses for more than 20 years. Based on decades experience and knowledge of this industry, Pingcheng is dedicated to giving customers honest prices. Once we get a quotation requests, we look at the drawings and simulates using specialized software immediately, and offer the best solution with proper prices.