Ever wonder how toys, containers and whatever else are plastic items assembled? It all begins with molditory factors. Like, a mold as in the hollow shape used to design things from materials such as plastic. This plays a significant role in the manufacturing process. There is a really neat type of mold that quite some companies utilize, this one called a clamp lock mold.

Clamp lock molds are unique, as they secure the two halves of the mold tightly with a robust clamp. Which creates an incredibly good seal, so when the plastic is poured in nothing leaks out. Since this air-tight seal is the thing that makes it so there are no more bumps or imperfections minOccurs in our end project. You are then able to slide the clamp spaces in or out for different materials and make sure everything stays tight while the plastic hardens.

Clamp lock molds, as the name implies, hold in place better and reduce final product errors Manufacturers do also have to ensure that their products are safe and meet with the necessary requirements, which can be done by simply stopping any leaks or problems from happening. This is vital for products such as food containers and medical supplies, in which safety is of the highest importance.

One of the best things to use in any manufacturing process is clam lock molds. The first one is that they work towards facilitating faster, higher-quality output (more stuff in less time from fewer workers). This allows the material to spread throughout the mold evenly, by providing a tight seal and saving repair/re-mold time. This eventuates in faster goods being produced which is favourable for businesses.

Being the second, these clamp lock molds also save money to manufacturers. This results in less waste -- and thus fewer defective items need to be produced, if no leaks or other problems prevent this. And therefore companies can pay less for the raw materials, and take tim doing them whichin turn let the company do each cheaper. In this way, they improve the product by improving it and also save organizations money.

As we move further along into the future and technology advances, clamp lock technology will play an even heightened role in mold-making operations. The use of 3D printers and computer designs will be a big help in this regard, as these new tools allow manufacturers to create molds that are much closer to the finished product. This just means you have a higher quality finished product and less mistakes during production.

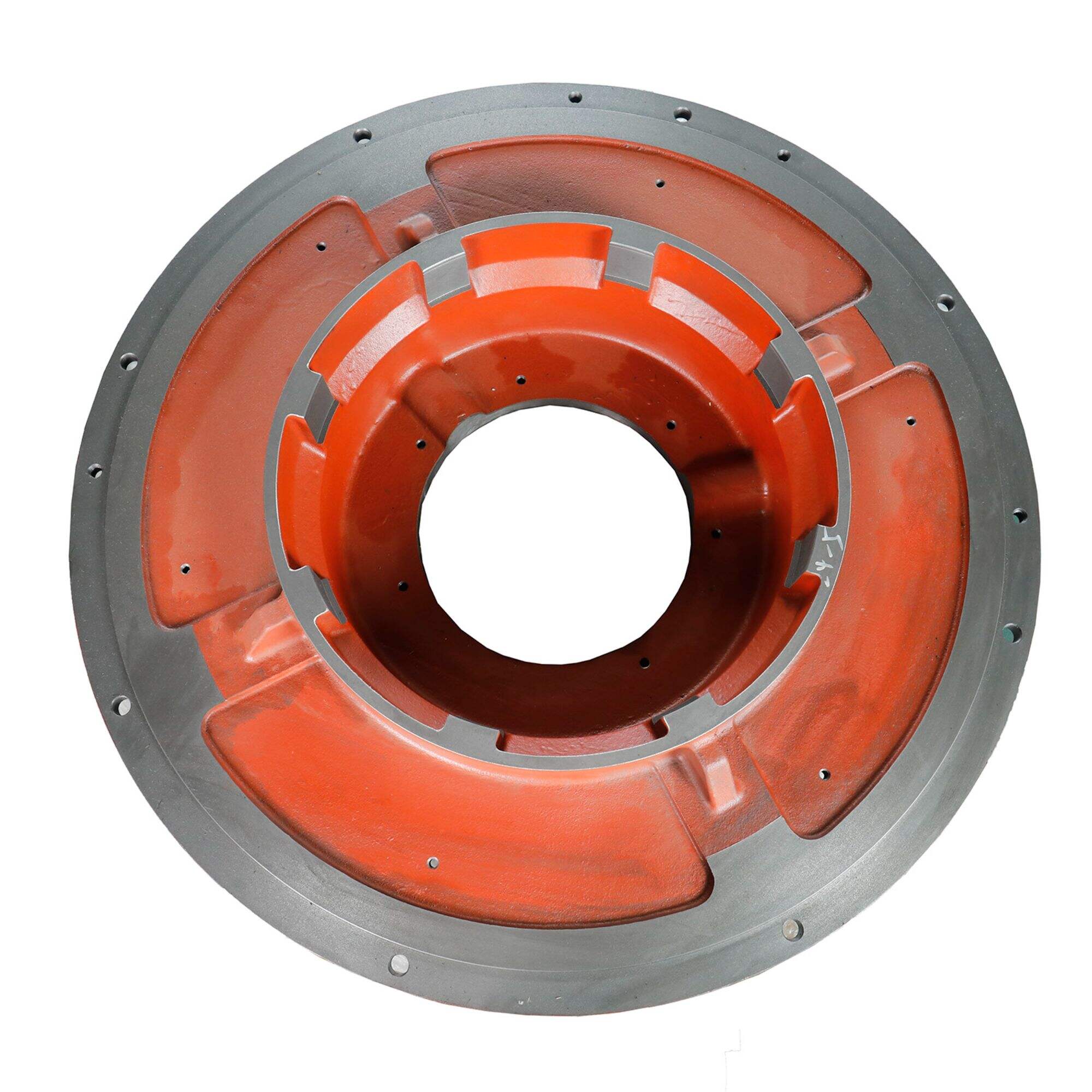

Manufacturers can improve their process of production better with clamp locks molds and using a type o f mold that is called multi-cavity mould. In the case of a multi-cavity mold, it features more than just one space (cavity design) and can also create many product parts simultaneously; It saves a lot of time and thereby increases the overall number of products that can be manufactured in one production.

Our customer services focused on your satisfaction. For over a decade we've provided machining services and clamp lock mold with well-known Japanese companies. Pingcheng's adherence truthful pricing is based upon our years of industry experience and knowledge of sector. We analyze the drawing special software and offer the best solutions for an affordable price once we have received an inquiry for quotes.

Pingcheng is clamp lock mold achieve their goals for business by providing our own supply chains and services solutions. We are focused on helping to extends the life and the values of your production. PingCheng could be the reliable supplier you requires. We are a trustworthy supplier who can offers you opportunities.

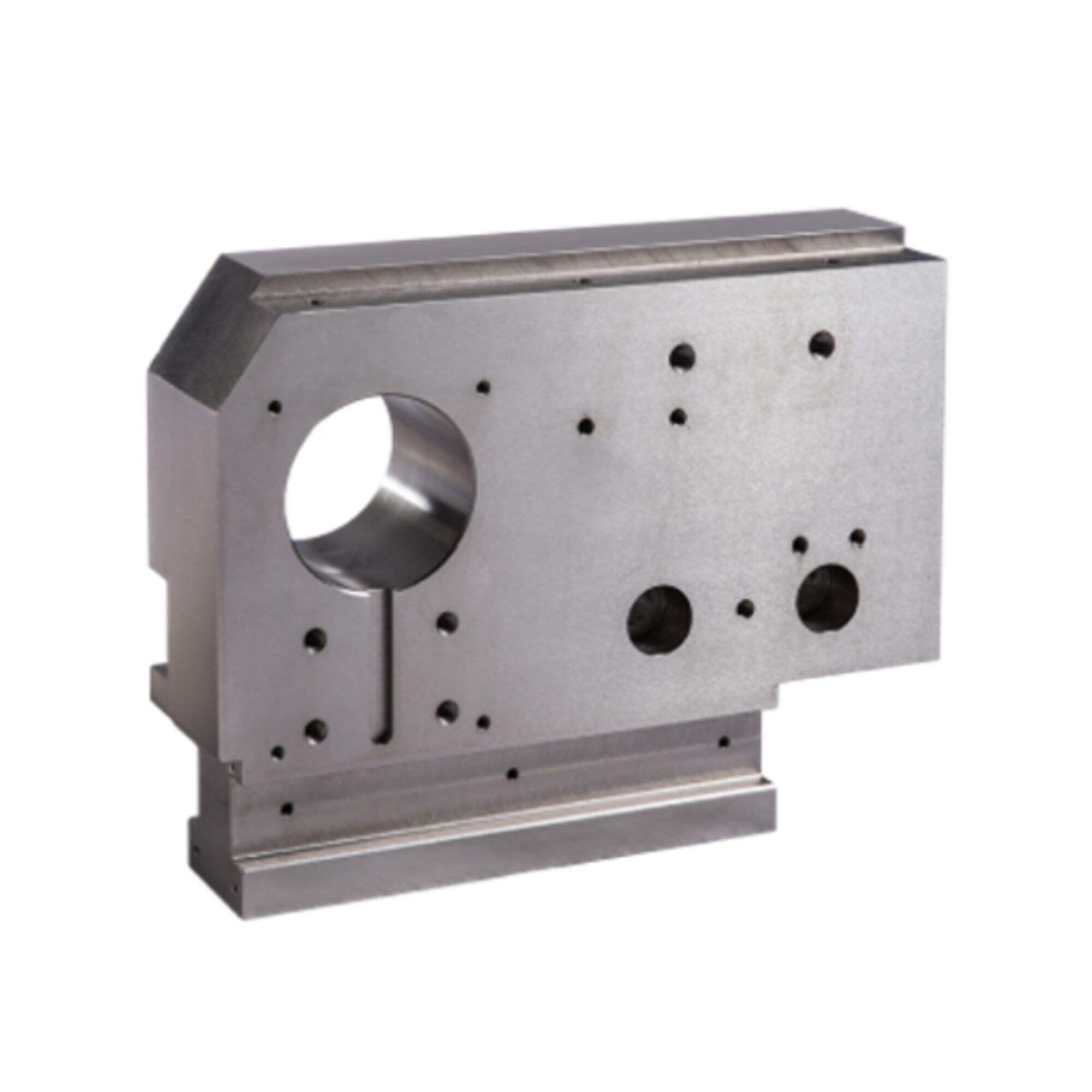

Pingcheng has now more than 20 manufacturing machines and clamp lock mold with years of experience. They aim at providing high quality. They then inspect the products by Mitsutoyo measuring tools and CMM that are calibrated on a periodic basis. Double-checking ensures that the product's quality precise and steady. Every key component is traceable and controlled during the machining process and assembly.

Pingcheng's clamp lock mold is based on decades of industry experience and understanding. We review the drawing, model it using specialized software and then provide the most competitive price.