How does hydraulic stroke technology work?, imagine a syringe that we chemically refer to as giving shots of something When we press the plunger of the needle, they force liquid through a very tiny and thin tubing. This pressure pushes medicine into the body. Similar is the principle of Hydraulic stroke technology. It uses a cylinder to pump liquid rather than a syringe, and the pressure created similarly pushes the piston inside. In turn, this enables machines to carry out physically demanding and precise operations.

Hydraulic Stroke Systems are common in, and used for a variety of applications. Construction machines and air conditioning systems, elevators - they are used everywhere. The beauty of hydraulic stroke technology and one of the best things that came with it. This allows it to perform a variety of tasks, from assisting garage doors in opening all the way up and relocating very heavy loads by massive machines.

The Industries use Hydraulic stroke technology as a useful resource due to it being efficient and accurate. It runs smoother than gear and chain operated machines because it does its work with a liquid. This is especially useful in light of the fact that minimizing noise is a key consideration, for instance with air conditioning systems commonly used throughout homes and offices.

What is more, hydraulic stroke strategies are much better electricity conserving schemes in relation to some other mechanized devices. The liquid that is employed in hydraulic systems are supposedly of the kind which cannot be compressed, hence it does not get squished. As a result energy is not lost in transit from one point to another. So there is no power used by the system when it's not needed to operate, which results in an additional energy-saving by skipping this step compared with other systems.

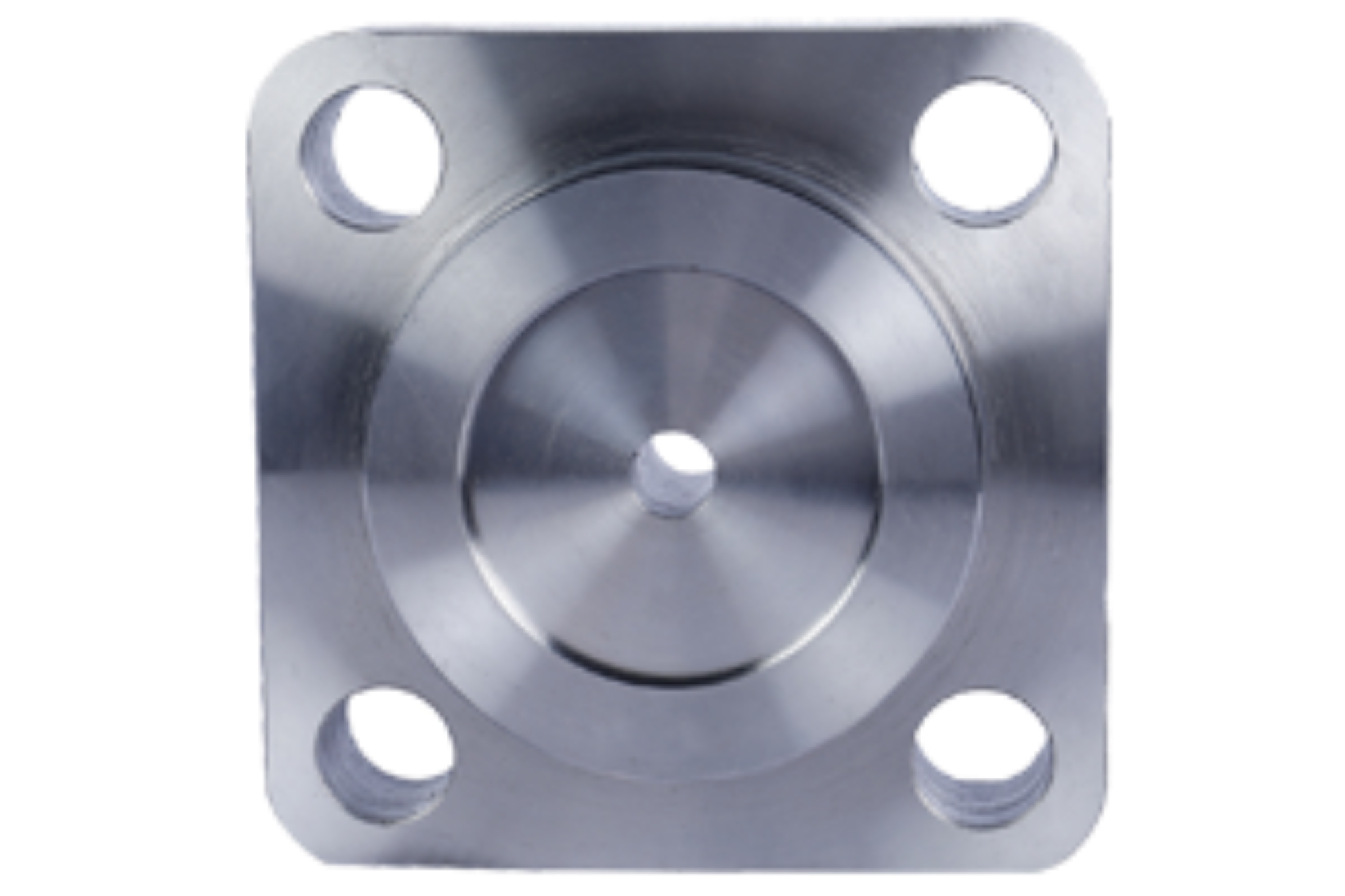

Larger systems and more powerful devices are several factors to consider when choosing hydraulic stroke parts, depending on the size of your system and how much power you want. By taking all these factors into account you'll be able to choose the right parts for your individual needs, guaranteeing that you get effective performance from your hydraulic system.

Similar to any other mechanical machine, the hydraulic stroke system requires proper maintenance in order for it remain functional. Important maintenance steps are frequent changing the liquid in the system, examination of mechanical hoses and also tubes is any kind of leaks as well as maintaining all-natural setting up particles free.

If you encounter any difficulties in your hydraulic stroke equipment, it is important to troubleshoot away the issue and resolve right immediately. Hydraulic stroke equipment: hydraulic strokes normally work fine but there can be some issues mostly related to leaks or valve problems. So these are the things you need to be able to debug any issue in order for it as not being resposive well and fix the root cause.

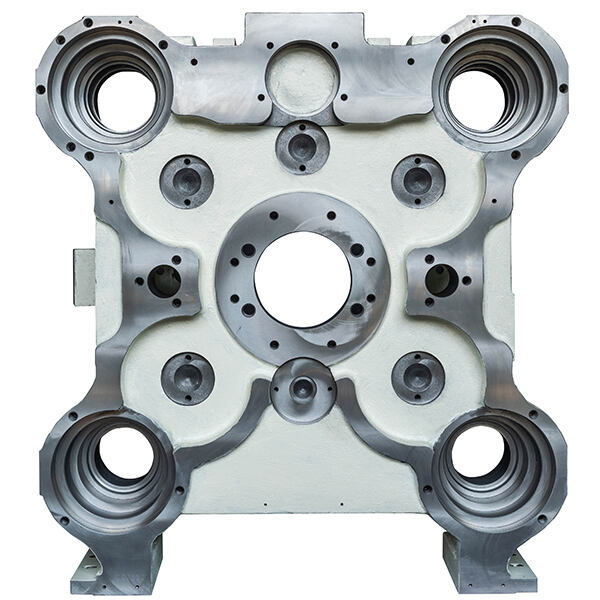

Pingcheng currently has more than 20 manufacturing facilities and 50 highly skilled technical employees. They hydraulic stroke. Mitsutoyo's measuring instruments and CMM are periodically calibrated. The double-checking keeps our quality steady and accurate. The machining and assembly of all key parts are tracked and controlled.

Based on decades in experience and a deep understanding of the industry, Pingcheng is dedicated to offering customers a fair price. When we hydraulic stroke, we examine the drawings and simulate using specialized software right away, and then provide the best solution for your price.

The supply chain and services of Pingcheng is designed to assist customers reach their business goals. We focus on extending and hydraulic stroke. PingCheng is the reliable manufacturer you're looking for. We are a partner which delivers options.

Our customers service focuses your satisfaction. We've been providing machining services and hydraulic stroke with industry-renowned Japanese companies for more 20 years. Based on years of experiences and knowledge of the industry, Pingcheng is dedicated to offering our customers an honest price. We evaluates the drawings using special software and present the best solutions at the most reasonable costs once we have received requests for quotations.