Bearings are just one part of a bearing assembly that also includes housings and supports, enclosures designed to enable the rotation of other components like wheels or gears. Bearings function like wheels to reduce friction and enable such quiet mechanical operation. Housings, meanwhile, wrap a bearing in its cavity and act as cover casement that cinematically revolves around bearings to hold them securely from extrinsic harms like dirt particle,humidity or at extreme temperatures.

One way to show how a lot of bearings and housings work is using a bicycle wheel as an example. In a wheels you will have wheel bearings that plays important role how the cycling spinning well and then bearing housing used to protect this transmission device from contamination such as soil, dust etc. Also should also be mentioned here is in countless instances, without them enabling mechanical systems dependably complete their very specific tasks?>

Bearings and housing systemsLubrication is one of the chief contributors to its service life as well reliability in bearings /housing system. The lubrication as well plays a critical role in certain aspects like wearing of components, friction among moving parts etc;

There are oil, grease and dry lubrification in bearing maintenance housing. Oil is what you might use on low-load/high-speed scenarios and grease would be an obvious choice for applications with slightly more demand/ lower speeds. Dry lubricants like graphite and molybdenum disulfide (MoS2) are known for their performance in high temperature, extreme pressurization scenarios.

Selecting appropriate bearing and housing should ensure not only of highest performance capacity but as well with durability. To choose which bearing type to use in a given application, the combined radial and thrust load that will be placed on it must first be evaluated along with any speed limitations or other considerations. For instance, if you are looking to build a high-speed machine then it requires that the bearings should be rated for similar RPMs as well.

The market is full of different types for instance ball bearing, roller bearing and plain bearing. Naturally, this family of choices includes ball bearings that provide extremely fine tolerance classes and are low frictional along with the dwell-free as well as noiseless operation. Allow high load carrying capacity,require heavy loads/are best suited for higher-speed applications.Use rollers to balance shaft revolution.

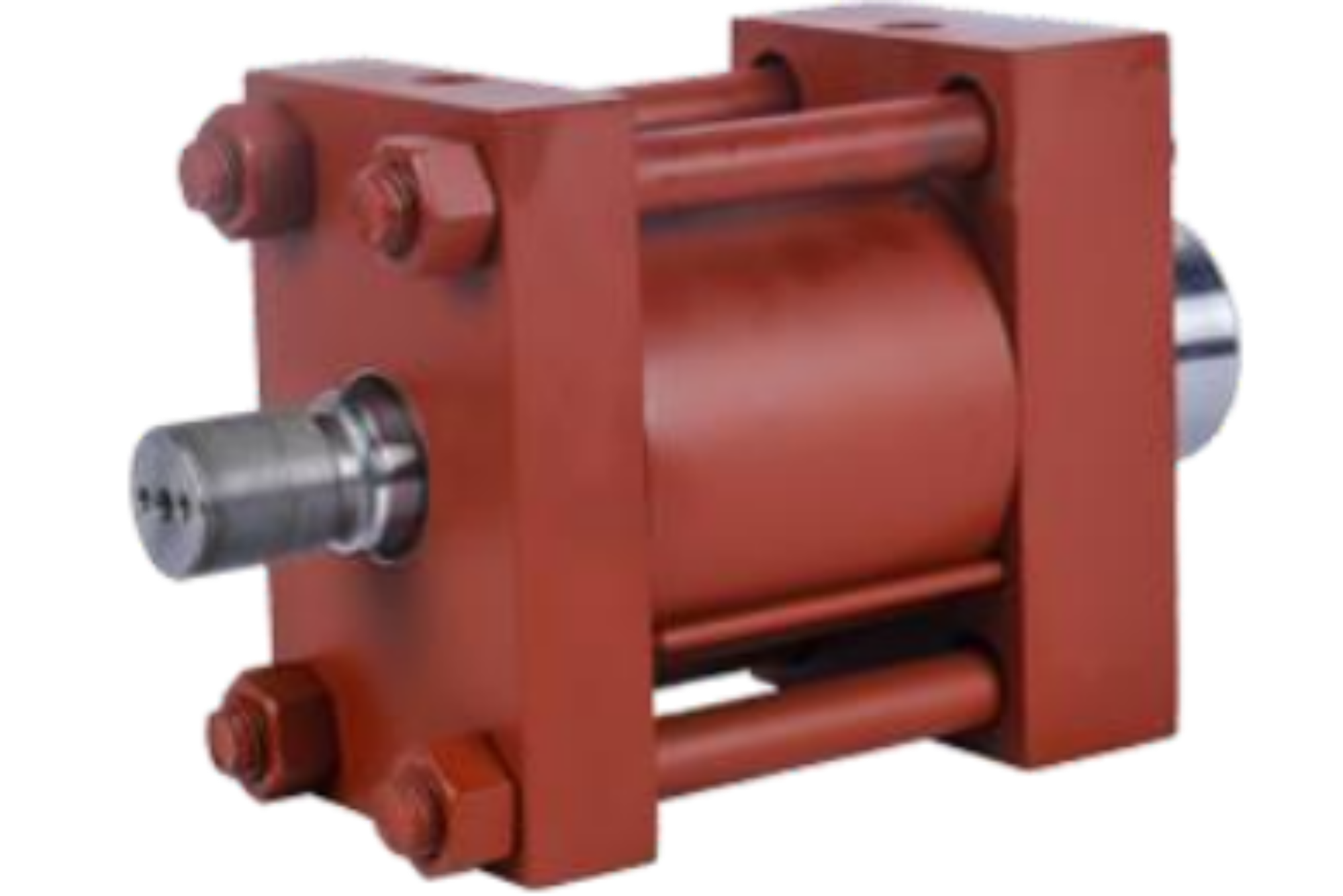

A housing is just the size, and shape of the bearing mounting. They are made of cast iron, aluminum and plastic; each has its own advantages as well as disadvantages.

Even the most fervent maintenance proponent can run into bearing and housing issues. Heard strange noises, suffered overheating and endured violent shaking while using a 2018 Compass. Whenever systems or services fail, approaches need to be systematic and careful in order to troubleshoot the problem effectively root cause analysis and avoid future failures.

Excessive Vibrations may mean misalignment, imbalances or bearing worn out and noise could indicate burner need lubrication treatments of parts which are decomposing. More often than not, overheating begins with bearings getting overloaded or creating excess heat through friction.

They wear out over time, so monitoring them is a must and addressing it ASAP if they're worn from regular inspection of the routine repair in case later on their bearing or housing system have lived longer than expected. By using a trained eye to inspect components on regular intervals, problems with worn bearings or broken housings can be addressed early enough before they become your next headline. Well, no one will ever play down repair tasks as... let's say replacing bearings or re-filling those oils that the goods continuing operation is and has always been dependent on.

Worn components, insufficient lubrication, and the influence of elements such as dust or moisture are screened meticulously during inspection. All other repairs required in order to comply with the manufacturers replacement parts and lubricants as needed for immediate repair

This is where the crucial bearing housing systems come to play, for all mechanical parts need an interplay of complex and efficient workability in order that each one works together succinctly. That also says needed maintenance and care (dah, correct lube, very good parts selection) is best way to explain the life & top performance for this kind of unit(s). So, by knowing about the bearings and housing systems and still following good maintantance act as per these guidelines people can sure their applications will work properly even after many years.

Pingcheng is now bearing and housing and 50 highly skilled technical employees. They committed to providing highest quality. Mitsutoyo's measuring instruments and CMM are calibrated regularly. The double-checking keeps quality reliable and accurate. The machining and assembling of all keys components are easily traceable and controlled.

Based on decades of experience and bearing and housing, Pingcheng is dedicated to providing its customers with a fair price. We examine the drawing, model it with specialized software and then give you the most affordable price.

The supply chain and services of Pingcheng are designed to help clients achieve their goals in business. We concentrate on extending and increasing the potential and lifespan of your manufacturing. PingCheng is a bearing and housing you've been searching for. We are a partner which delivers opportunities.

Pingcheng is a bearing and housing and lifecycle partners. The shipping of our products is only the beginning of our partnerships. Our customer services is about ensuring your satisfaction. Since more than 20 years ago, we have offered manufacturing services and have built a closed collaboration with well-known Japanese firms. Pingcheng's dedications to fair pricing is based upon our years of experiences and understanding of this sector. We analyze the drawing in an advanced software program and then provides the most efficient solution at the most reasonable cost once we have received the requests for quotation.