However, in the manufacturing world, people do use several tools and machines to help them in producing various items. A very important machine in this process is the bearing CNC. As we expect, this kind of machine is responsible for the parts of the machine that must be in place for the other machines to work well at all. A bearing CNC cuts a material shape using precise computer-controlled techniques.

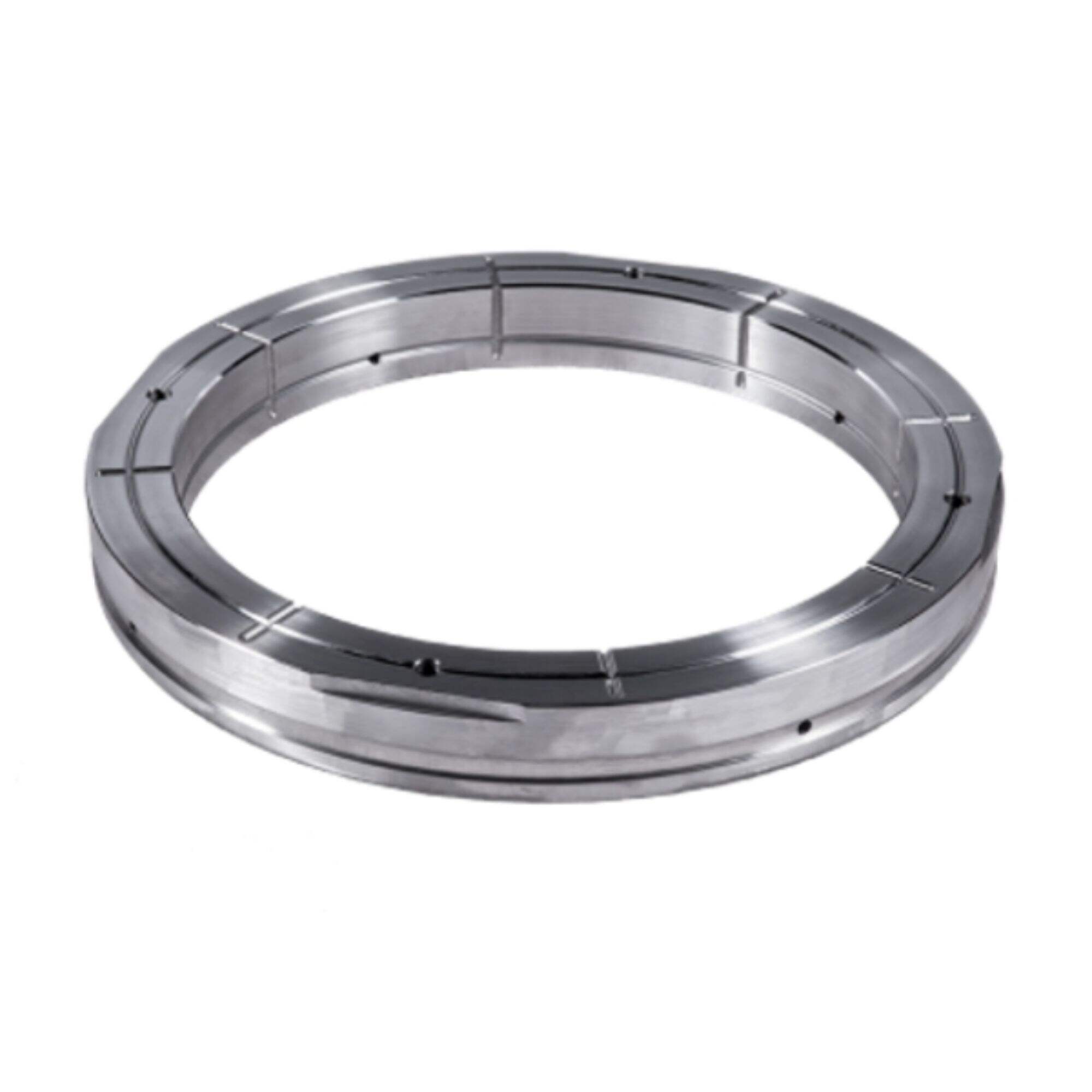

One of the parts of a machine is something called a bearing. This is important because it is responsible for the moving mechanism of the machine and how accurately it performs, also the Pingcheng's product such as linear slide rail bearings. This fluid motion allows the machine to make very precise cuts. Despite the potential complexity of the term "bearing CNC," it all sounds pretty simple after you get down to the specifics. The main concept is that the cutting tool is guided by a computer which allows it to produce shapes with high dimensional accuracy.

A rear CNC is capable of making very accurate cuts, which is one of the most impressive aspects of utilizing a bearing CNC. As the cutting is done by a computer, it can make cuts much more precise than a person can make by hand. Such accuracy is critical for producing high-quality parts for different kinds of machinery.

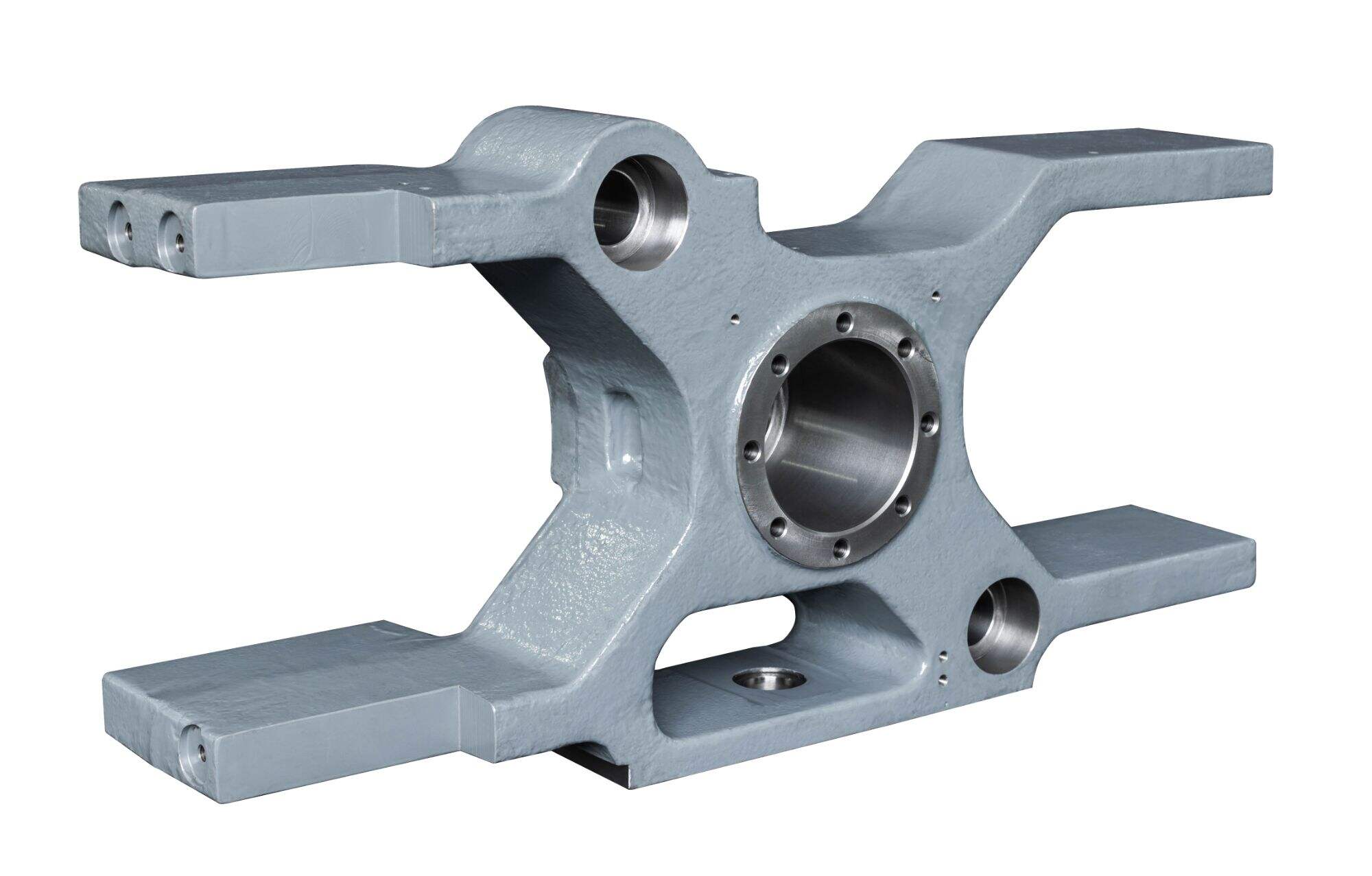

A machine is structured by building different parts, same with the moving platen supplied by Pingcheng. The parts all have to connect at just the right moment and place for the machine to work right. If even one part is off, everything else can come to a grinding halt. This is where the operating CNC comes in. You can do it with incredible accuracy with this machine, all these parts. In this way, the whole machine will run smoothly and saves replacement for unnecessary parts.

Aside from precise, bearing CNC machines contribute to quicker and more effective manufacturing processes, similar to the Pingcheng's product like 30 ton cylinder. It is all done by the computer program behind the machine, meaning it could operate far more quickly than a human would ever be able to. And, being a machine, it’s not prone to making the same kinds of errors that people do. A CNC bearing works much faster and provides much more accurate part manufacturing than older process.

To use a bearing CNC machine, you will learn to design a part using specialized computer software referred to as CAD computer-aided design, just like the clamp mold developed by Pingcheng. Use of CAD software: CAD refers to Computer-Aided Design, and you can create a 3D model of the part you are manufacturing with its usage. The model can be sent to the bearing CNC machine for part design once you have designed the part.

One of the coolest upgrades comes in the form of AI getting integrated into the production process to make it better, along with Pingcheng's product robotic base. Through the analysis of data from past manufacturing runs, AI can be used to predict when certain parts will fail. Then this information can be used to recommend changes to the manufacturing process. All of these innovations free up companies time and money by minimising unnecessary repairs or tweaks needed.

Our customer services focused on your satisfaction. For over a decade we've provided machining services and Bearing cnc with well-known Japanese companies. Pingcheng's adherence truthful pricing is based upon our years of industry experience and knowledge of sector. We analyze the drawing special software and offer the best solutions for an affordable price once we have received an inquiry for quotes.

Pingcheng's Bearing cnc and services are designed to helps customers meet their goals for business. We are focused on expanding and increasing the potential and lifespans of your productions. PingCheng is a dependable producers you are looking for. We are a suppliers that provides opportunities.

Pingcheng today has more than 20 manufacturing facilities and more than Bearing cnc. They aim at providing high quality. Mitsutoyo's measuring devices and CMM are regularly calibrated. Double-checking helps keep the accuracy of our products and steady. Every single component can be traced and monitored during machining and assembly.

Pingcheng's Bearing cnc is based on decades of industry experience and understanding. We review the drawing, model it using specialized software and then provide the most competitive price.