Low Pressure Casting is a Special and Interesting Way to Manufacture Metal Components for Several Applications With this process, pressure is used to assist the metal reach its right shape. This is key because it prevents from creating strong looking metal objects.

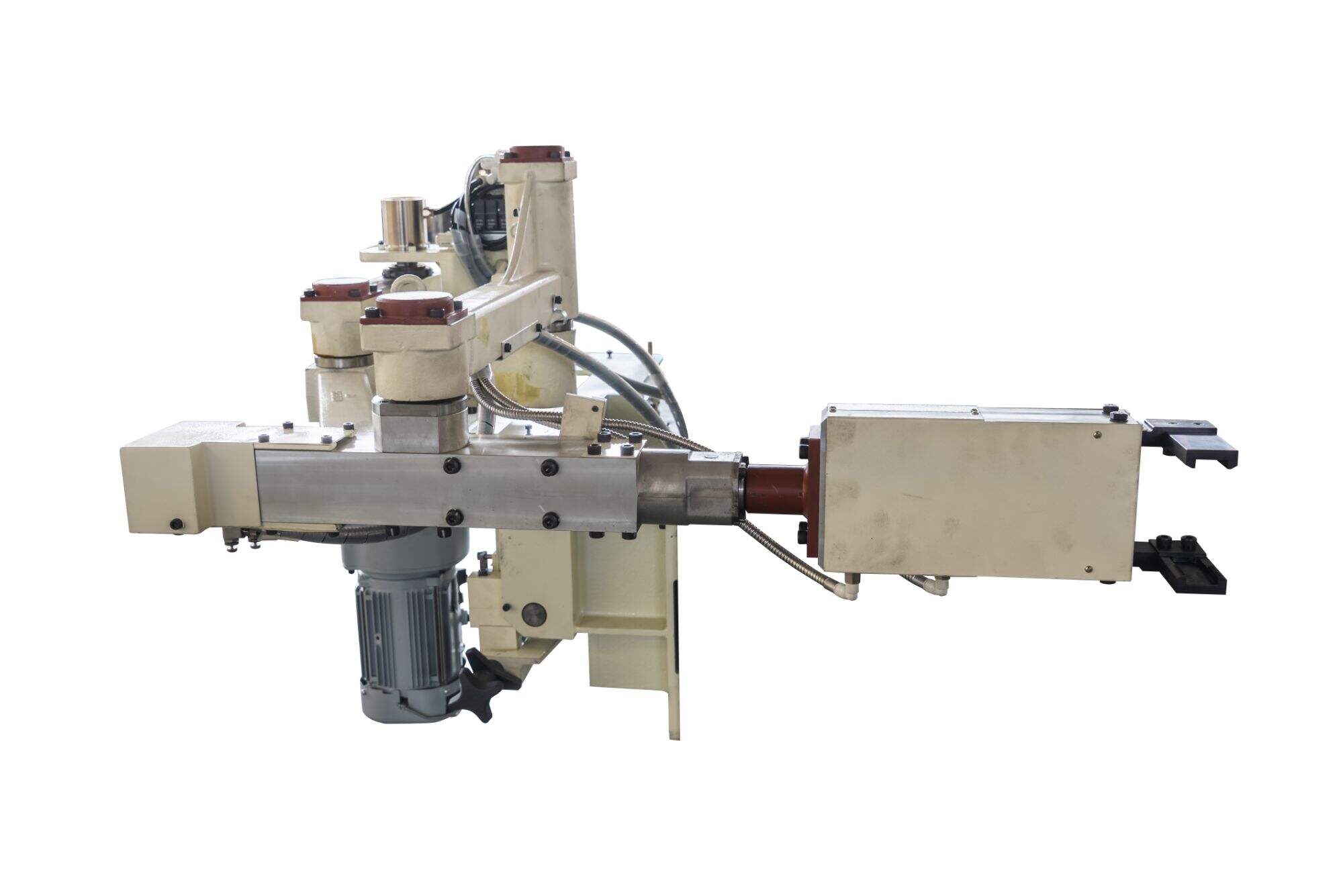

Low-pressure casting is a Technology: This process allows the creation of metal components through a unique professional machine. This press feeds liquid metal into a mold, which is an empty shape that will determine the final product. This low pressure applied to the metal allows the liquid metal to flow into all of these very small crevices in throughout this mold role. The method is widely used to produce numerous everyday items that are made from the metal material like parts of a car and attractive designs in metals which you can find in any appliance or home decor.

Low Pressure casting is well received because it allows for the manufacturing of high quality metal products. The metal, when poured into the mold fills and covers all of this space evenly. This created an equal spread, for a very strong and durable product that will last years without cracking or breaking. That also makes it easy for you to have the smoothest areas on your metal things using low pressure casting. This cleanliness is really crucial for items like auto products because they must run well and look nice to bring in possible consumers.

This can also be a good thing because it allows for less straightforward forms to made with low pressure casting but unfortunately the vast majority of wheels are simple 1 piece designs. At times metal parts contain many little features, bends, or custom shapes that must be perfect. As the metal flows into even the smallest areas in the mold, this guide pressure provides by device compels within low stress spreading. This means that it has ability to produce an efficient end product which is fully compliant with all the details of design. A little helper that makes sure every llittle thing, is just right.

For those, therefore who are making a metal part for their project or even wishing to know the best way of getting rid of small blasts, you might be wondering whether low pressure casting is new and lightest alternative that can help. Well, that really depends on what you are manufacturing and by far even a more complex question is what role in the assembly do your parts play. Not all projects can be cast using investment casting or it might not be the ideal method for that type of project. This is why you should consult an expert who knows all about this. They can be valuable in helping you determine the best means for your particular project to ensure that it is a grand success.

Low pressure casting is one of the best technologies for metal parts. Like I said earlier, it gives you final quality metal (with polished surfaces) It's very beautiful. This makes it an effective process for producing metal parts in batch if you need a large number of pieces made, quickly. Yet there are some downsides to keep in mind, too. This process, for example, is limited to certain metal types and may not be the most suitable in all cases of manufacturing specific geometry. When implementing either of these approaches it is critical that you consider both pros and cons.

Pingcheng is now home to more than 20 manufacturing facilities and 50 experienced technical workers. They low pressure casting. Then, the product is inspected by Mitsutoyo measuring instruments and CMM that are periodically calibrated. Double-checking makes sure that the quality of our products precise and steady. The machining and assembly of all the key components are controlled and traceable.

Pingcheng is a low pressure casting and lifecycle partners. The supply of the products is just the beginning of our partnerships. Our customer service is about ensuring your satisfactions. We have been offering the machining services and establishing a close partnerships with well-known industry Japanese companies for more than 20 years. Based on decades of experiences and knowledge of this field, Pingcheng is dedicated to offering our customers an honest prices. We examine the drawing with an advanced software program and then provide the best solution at a reasonable prices once we have received the requests for quotation.

The supply chain and services of Pingcheng are designed to aids clients achieve their goals in business. We low pressure casting as well as maximizing the values and life of your manufacturing. PingCheng is a dependable manufacturer you are looking for. We are a suppliers that offers a variety of options.

Pingcheng's low pressure casting is based on decades of industry experience and understanding. We review the drawing, model it using specialized software and then provide the most competitive price.