The advancement in plastic manufacturing will not be possible without the process of injection molding. This is the process of molding a shape by melting plastic pellets with heat and hydraulic press. Vertical Hydraulic Injection Molding Machine is one of the most unique types of injection moulding machines. 2021-03:What can a vertical injection molding machine offer for toy industry. This article introduce new type of vertical clamping from taiwang machinery, how competitive of the great features and accurency.In todays talking about this competitiveness.

True to the industrial revolution, notably in plastic products production, are actually vertical plastic injection moulding machine. The machines work in a vertical design with the mold lying flay above and injection unit swinging from underneath. These are some of the advantages provided by this unique design over vertical Injection Moulding machines:

There are a number of key benefits to vertical hydraulic IMM compared with horizontal offerings. There main advantages are their small and accessible design. These machines are vertical in operation so they require less floor space; making them perfect for smaller machining facilities. Another big advantage is that they are power efficient as well. They even higher that come with power saving hydraulic system, which gives overall less energy consumption. In the longer term, this could account for very substantial savings in energy costs to a manufacturer.

How Vertical Clamping Can Improve The Quality Of Your Product - Advantages of Using A Vertical Hydraulic Injection Moulding Machine

2. By improving product quality - Due to the hydraulic changes in Pingcheng vertical injection molding machine price results will improve recycled material, making it even more quantitatively available for many other industries. They not just achieve that by reducing the waste on materials. They are able to save cost and material, because of their construction allowing the gravity use in their vertical operation. This equipment also enables exact dosing of the injection And since it forms a hydraulic system that maintains pressure constant, retains uniformity in plastics to be injected into the mold. The consistency that it brings, adds quality and standardization to the products.

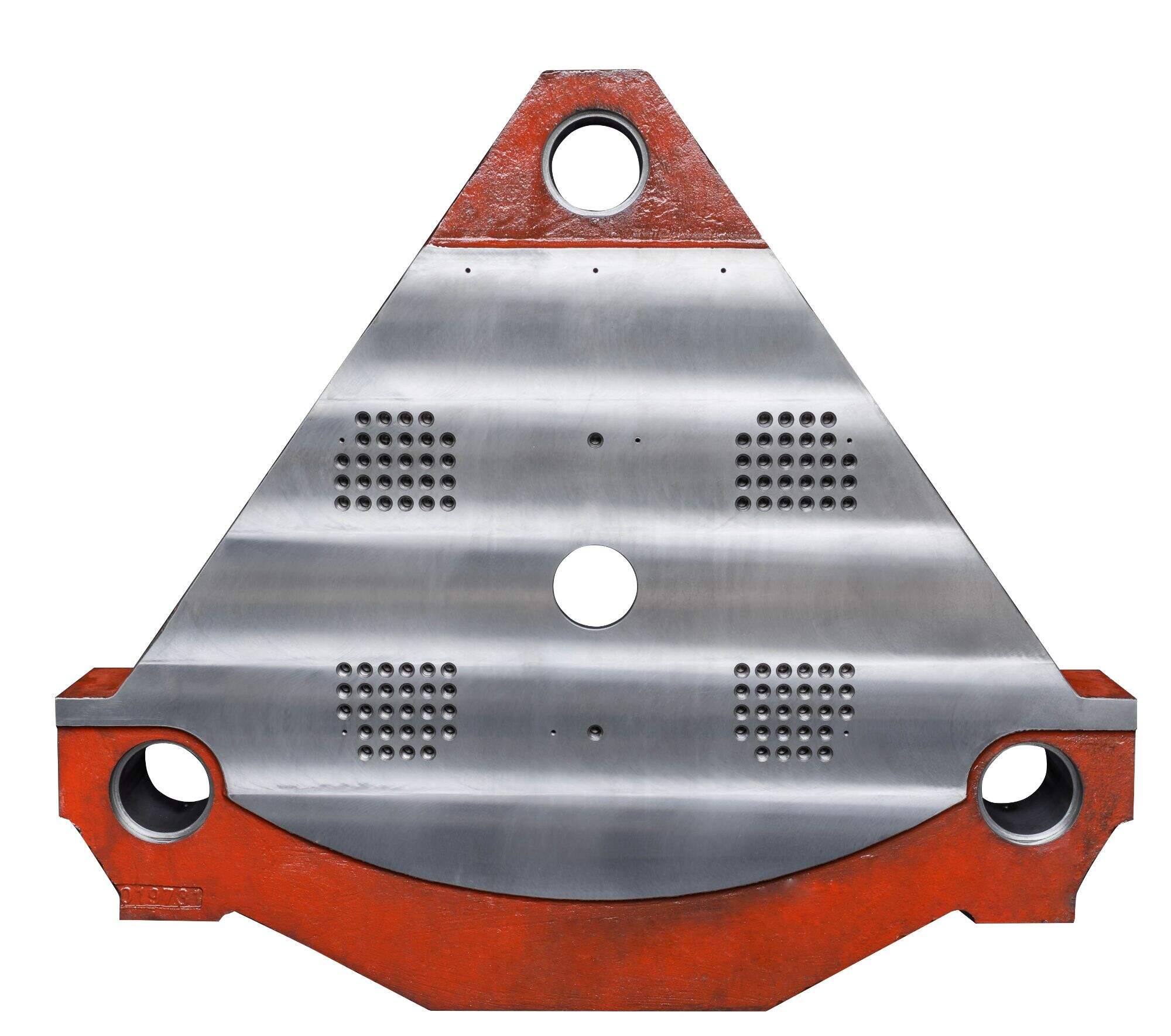

Vertical hydraulic injection moulding machines are another type that get attention for its versatility. Plastic mold machine can be used to manufacturing different types of Plastic products like small components as well large parts. The Pingcheng vertical plastic injection machine are also able to work with a range of plastic materials, including polycarbonate, nylon and polypropylene. Another factor of their versatility is that they can manufacture a wide range of products. They can machine complicated parts including undercuts and internal and external threads.

The uses of vertical hydraulic injection moulding machine are manifold and it is used in many car parts, automotive parking tools and primers for high-performance macroeconomic yards like medical systems. These vertical injection machine operate on the very clean mold that can be made from one cavity item to make a lot of products just as filler covers fuel tanks, bumpers with shells, dashboard assemblies etc. With these parts taking the brunt of abrasion and the elements they need to be built strong, especially if off-road driving is anticipated which mega points up how exact a hydraulic system must work. Medical sector use hydraulic vertical injection molding for manufacturing of syringes, IV bags and catheter. The Molding of Micro Plastic Product: For these products, sterility and precision are essential so the injection process has to be ingestible in order for a continuous throughput.

From this paper, it is apparent that the Vertical hydraulic injection moulding machine has brought a substantial change in plastic manufacturing sector. They are more environmentally friendly, and because of their manufacturing versatility can produce a wide range of products that horizontal presses cannot. In addition, you have a lot more control over the cycle and there is an incredibly consistent level of quality across your offering. The ability of other self-service machines to equal the flexibility, accuracy and quality. These Pingcheng vertical injection molding machine benefits differentiate it from other machines and are a fundamental reason for its popularity.

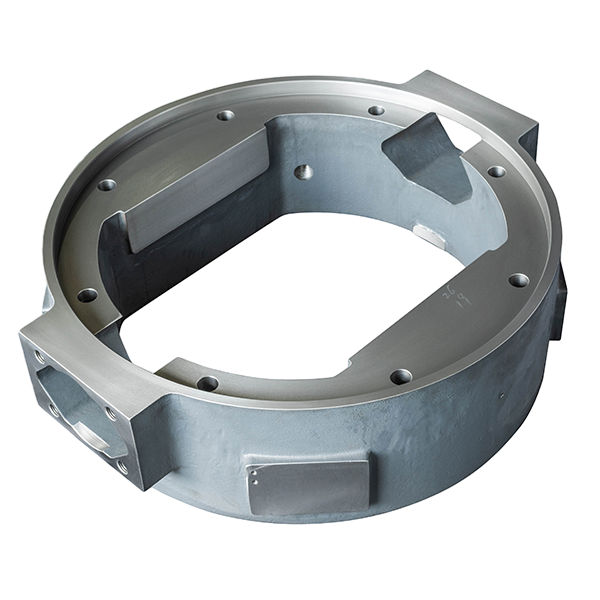

Pingcheng is now Vertical hydraulic injection moulding machine and 50 highly skilled technical employees. They committed to providing highest quality. Mitsutoyo's measuring instruments and CMM are calibrated regularly. The double-checking keeps quality reliable and accurate. The machining and assembling of all keys components are easily traceable and controlled.

With years in experience and a Vertical hydraulic injection moulding machine, Pingcheng is dedicated to providing customers with honest price. When we receive a the request for quote, we review the drawings and simulates using special software right away, and then provide the most effective solution with a fair price.

Our customer services focused on your satisfaction. For over a decade we've provided machining services and Vertical hydraulic injection moulding machine with well-known Japanese companies. Pingcheng's adherence truthful pricing is based upon our years of industry experience and knowledge of sector. We analyze the drawing special software and offer the best solutions for an affordable price once we have received an inquiry for quotes.

Pingcheng is Vertical hydraulic injection moulding machine achieve their goals for business by providing our own supply chains and services solutions. We are focused on helping to extends the life and the values of your production. PingCheng could be the reliable supplier you requires. We are a trustworthy supplier who can offers you opportunities.